Researchers in Glasgow, Scotland, have successfully 3D-printed a lithium-ion battery. The new battery is constructed using a polylactic acid (PLA) material with nano- and microscale pores to increase its surface area. The team's new method allows them to precisely control the size of the electrode pores and the electrode placement. The researchers used a biodegradable, bio-based material called polylactic acid, which is made from corn, sugar cane, and starch.

The company has achieved several milestones in its proprietary 3D-printing technology. The company has patented techniques for producing the three key elements of the battery. It has also researched the production of mass-produced batteries with greater energy density and higher charging cycles. The next step is to improve the battery's performance and efficiency. In the meantime, the team is focusing on minimizing energy and material wastes during the production process.

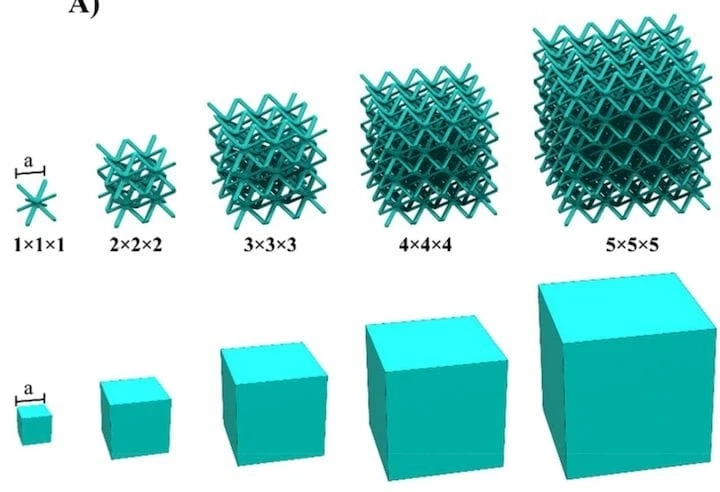

The process of 3D-printing allows thicker layers to be used for energy storage in the battery cell. This increases the gravimetric energy density by over 20 percent. Blackstone's technology also enables them to customize the cell size to meet customer needs, saving 15 percent of space and cost. Furthermore, the company claims that their technology is flexible and scalable, meaning they can build custom-sized lithium batteries. The company claims that it can save the consumer more than 70 percent of their CAPEX.

The three-dimensional printing process has a number of advantages. It reduces energy consumption by around 25%. The energy consumption is reduced by 20%. Moreover, it provides 20% more energy density and less inactive material than traditional batteries. It also allows them to be customized and shaped, meaning they can be molded into any shape and size. These benefits will translate into higher energy-density for portable electronics and electric vehicles.

The technology utilises a water-based process that allows the three-dimensional printing of lithium-ion batteries to be manufactured to customer specifications. The three-dimensional printer can produce the three elements separately and then put them together in a casing. This makes the process eco-friendly and helps reduce waste materials. It also produces a battery that weighs only 1.5g. In addition to this, it also reduces energy usage by 25 percent.

The Swiss firm has made breakthroughs in 3D printing solid-state lithium-ion batteries, announcing a new manufacturing facility in Dobeln, Germany. The process has shortened the production process and ensured long-term access to battery materials. It also cuts energy consumption by 25 percent, which is crucial as the drying process accounts for up to 57% of the total energy usage of batteries. Its 'Thick Layer Technology' reduces inactive material and costs by 20%. The company's proprietary method has a flexible process that can produce any shape.

The researchers used a special ink that could be 3D-printed to create lithium-ion batteries. The new ink also possesses titanium oxide particles that can be directly deposited into the battery. By using this ink, the team was able to produce a battery with better performance than existing conventional methods. Further tests revealed that the printed battery had enough energy to power a green LED for 60 seconds. The technology was initially used in a prototype and is now widely available.

0