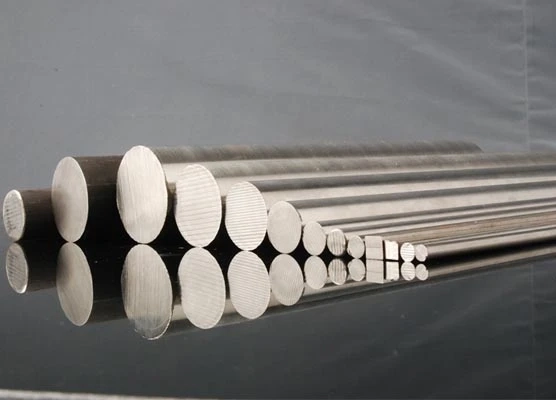

If you are looking for alloy steel that is affordable, solid, and easy to work with, then the Alloy Steel F12 rods might be the solution you need. Though not very well-known in general, this type of steel is a great choice for manufacturers and users who want to get their hands on a reliable material at a competitive price point. If you would like to learn more about this uncoated alloy steel and why it’s such a good choice for many different applications, keep reading!

This article will explain everything you need to know about the F12 alloy steel rods so that you can make an informed decision before buying any materials.

What is F12 Alloy Steel?

F12 alloy steel is an uncoated low-carbon alloy steel that is typically used for general engineering purposes and manufacturing. This means that F12 is extremely useful for creating parts for a variety of different industries and applications, including agricultural, chemical, construction, food and beverage, industrial, mining, power generation, refineries, and more. F12 is low-alloy steel that is made of Iron as the main component, along with other trace elements and special chemical compounds that make it a little different from standard Iron. These trace elements and compounds are what give each type of steel its specific properties. Because of these trace elements and compounds, F12 alloy steel has excellent resistance to corrosion and oxidation, making it a great choice for a wide variety of applications and industries where corrosion might be a big problem. It is also very easy to process, which makes it a great choice for those who don’t have a lot of experience working with metals.

Why Use F12 Steel?

As you’ve already read, F12 is a great steel for a wide variety of applications due to its corrosion resistance, high strength, and easy processing. It is also very affordable, which makes it a great choice for those who are on a limited budget and need to control costs. In general, F12 is an excellent choice for general engineering uses and manufacturing because it has everything you need in one material and at a price that fits almost any budget. In addition to all of these benefits, F12 alloy steel is very easy to work with, which makes it a great choice for those who don’t have a lot of experience working with metals or need to work with materials that are easy to handle. Despite being easy to work with, this material offers great strength and resistance to corrosion, making it a great choice for numerous applications and industries.

F12 Alloy Rod Manufacturing Process

The manufacturing process of F12 alloy steel rods is very similar to the process of making other types of uncoated low-carbon steels. The main difference between these materials and F12 is that F12 is a fully killed steel, meaning that it has a controlled carbon content, which makes it more corrosion resistant. To make Alloy Steel F12 Rods, the steel plant starts with a fully cleaned and inspected iron ore. After that, the iron ore is smelted to remove impurities, creating pig iron. Next, the pig iron is refined through a process called carbon decarburization, which removes the carbon impurities and creates uncoated low-carbon steel. Finally, the uncoated low-carbon steel is killed and converted into F12 alloy steel.

F12 Alloy Rods Properties

Corrosion resistance: The main reason why F12 is such a good choice for so many applications is its excellent corrosion resistance. This steel has a very low carbon content, which makes it a great choice for applications where corrosion is a big problem. Because of its low carbon content, F12 has excellent resistance to corrosion and oxidation, making it a great choice for a wide variety of applications and industries.

Strength: The main component of F12 is Iron. Because of this, F12 has excellent strength, making it a great choice for those who plan on using the materials they create for heavy-duty applications where high strength is needed.

Ease of use: F12 is low-carbon steel, which makes it easy to work with and process. Because it is low-carbon, this material is very easy to cut, shape, and machine, making it a great choice for those who don’t have a lot of experience working with metals.

Benefits of Using F12 Alloy Steel

Affordable: Alloy Steel F12 is an affordable uncoated low-carbon steel that is very easy to process, making it a great choice for those on a limited budget who need to control costs. This material is an excellent choice for general engineering uses and manufacturing because it is affordable and easy to work with steel.

Easy to work with: Because F12 is low-carbon steel, it is very easy to work with, making it a great choice for those who don’t have a lot of experience working with metals. This steel is easy to cut, shape, and machine, making it a great choice for those who don’t have a lot of experience working with metals.

Excellent corrosion resistance: The main reason why F12 is such a good choice for so many applications is its excellent corrosion resistance. This steel has a very low carbon content, which makes it a great choice for applications where corrosion is a big problem.

F12 Alloy Steel Rods Properties and Specifications

Standard: ASTM A182 / ASME SA182

Dimensions: ASTM / ASME

Thickness: 50 mm to 6000 mm Long

Length: 1 To 6 Meters, Custom Cut Length

Form: Round, Square, Hex (A/F), Rectangle, Wire (Coil Form), Wire mesh, Billet, Ingot, Forging Etc.

Alloy Steel F12 Rods Manufacturer, Alloy Steel F12 Rods Stockist, Alloy Steel F12 Rods Supplier, ASME SA182 Alloy Steel F12 Rods, Alloy Steel F12 Rods Supplier in Mumbai, India.