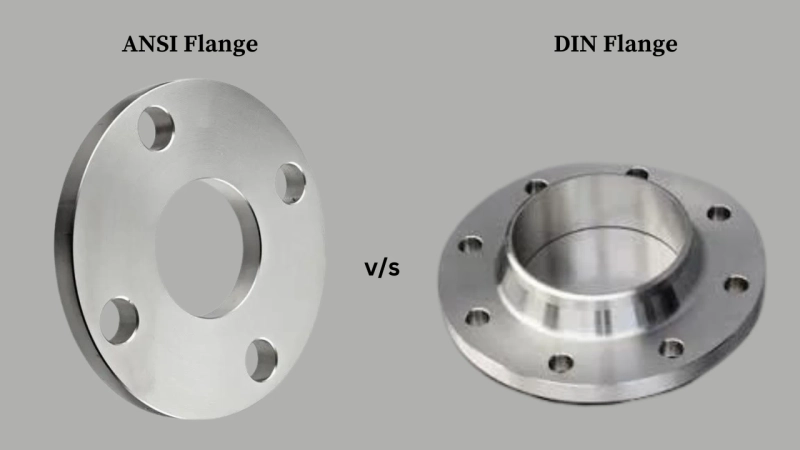

If you're curious about how DIN and ANSI flanges are different, you're in luck! Flanges are important for connecting pipes, and it's key to pick the right type for things to go smoothly. In this blog, we'll explain the basics in simple terms. We'll look at the features of ANSI and DIN flanges. Knowing about these standards helps with your projects. Let's talk about flanges easily and make your next choice super easy!

ANSI flanges

Definition

Let's talk about ANSI Flanges, which are strong metal connectors used a lot in American industries. ANSI is commonly known as the American National Standards Institute.

These flanges are like the reliable hometown heroes for many projects in the United States. They work well with local standards and are popular because they are dependable.

Purpose and use

Now, what makes these ANSI Flanges special? Well, they come in different types and sizes, each serving specific purposes in machines and projects. Whether it's welding neck or slip-on flanges, they've got it covered. If you're working on a project in the U.S., you know about these.

Now, let's talk about the advantages. ANSI Flanges are familiar and easy to use in the U.S. They work well with American equipment and standards. But here's the thing – they are not as well-known outside the United States. If you're working on a project globally, people might not be as familiar with them.

DIN flanges

Definition

DIN Flanges, also known as Deutsches Institut für Normung Flanges, are important in industries, especially in Europe and around the world. These flanges follow specific rules set by a German organization to make sure they work well with many different things.

Purpose and use

DIN Flanges come in different types and styles, giving them the ability to fit different needs. One good thing about them is that people everywhere agree to use them, making them a top choice for projects worldwide. They can work well with parts from different places, making things simpler.

These flanges are known for being very exact and trustworthy. The rules not only talk about how big they are but also what they comprise and how to test them, making sure they are good quality. This is especially important in industries where safety and how well things work are really important.

Even though DIN Flanges are popular in Europe, it's good to know that they might be less common in the United States. This is important when working on projects with mostly American things. But because people around the world agree on using them, DIN Flanges are still a good choice for projects that involve many different places.

Key differences between ANSI and DIN flanges

Picking the right flange is super important in the world of industrial fittings.

Let's talk about the main differences between ANSI and DIN flanges and break them down in simple terms.

Size and shape

ANSI flanges are like using inches, while DIN flanges are more like centimeters. They're similar but use different scales.

Handling tough conditions

Think of your flange as a superhero for tough industrial tasks. ANSI and DIN flanges have different abilities when it comes to handling pressure and temperature. ANSI is like the American hero, and DIN is the European hero. Knowing these differences is crucial for making sure your flange can handle the heat of the job.

Fit and seal

Imagine flange faces as puzzle pieces that need to fit perfectly. ANSI and DIN flanges have different shapes of puzzle pieces. ANSI flanges have flat or raised faces, while DIN flanges have a special groove face. This also applies to gaskets, the rubbery parts that make sure everything stays sealed tight. Matching these pieces is important to avoid leaks and keep a strong connection.

In simpler terms, ANSI and DIN flanges have their own languages – different ways of sizing, handling pressure, and even the shapes of their faces. So, picking between them is like choosing between a hamburger and a sandwich – both are good, but with small differences that suit specific preferences.

Choosing the right flange

When it comes to industrial parts, picking the right piece for your job is super important to keep things running smoothly. Let's make it easy to understand.

Deciding between ANSI and DIN flanges depends on what you need for your project. Here's a simple guide:

Think about your project

When choosing a flange, think about your project. Consider things like what equipment you're using, how much pressure it needs, and what materials are involved. ANSI is often used in the United States, while DIN is used more around the world. If your project is in the U.S., go for ANSI. If it's international, go for DIN.

Consider international projects

If your project is in different countries, choose a flange that's accepted everywhere. DIN flanges are handy tools used in many projects, so using them could make your project simpler. But if your project is only in the U.S., ANSI flanges might be easier to find and less expensive.

Ask experts for advice

Talk to professionals like engineers. They know a lot about what your project needs. They can help you understand the differences between ANSI and DIN flanges so you can make a smart choice.

Choosing the right flange (ANSI or DIN) makes sure everything works together well and is safe for your industrial projects. Pick the one that fits your project's needs, whether it's ANSI for a U.S. project or DIN for projects all around the world. Your choice matters for your industrial work to be successful.

Conclusion

When you need flanges for your projects, trust Texas Flanges. We know all about ANSI and DIN flanges, so we help you pick the right ones for smooth operations. Our Texas Flanges team is committed to giving you high-quality solutions that fit your needs.

Whether you want reliable ANSI flanges or widely accepted DIN flanges, we've got you covered. Choose Texas Flanges for your projects because we have the expertise for excellent results.

Your success is important to us; we're here to help you at every step. For strong, reliable, and effective flange solutions, Texas Flanges is the name to rely on. Get in touch with us today for flanges that last a long time.

FAQs

What's the big difference between ANSI and DIN flanges?ANSI flanges are American, and DIN flanges are European. The main differences arise from their sizes, their capacity to handle pressure, and their common usage locations. To pick the right one, think about where your project is and what matches up with it.

In the U.S., folks like using ANSI flanges because they follow American rules. But if you're working on a project anywhere else in the world, DIN flanges are a good choice. They're accepted globally and fit well with different equipment and situations.

Look at where your project is happening and where your equipment comes from. If it's in the U.S., go for ANSI. If it's somewhere else, consider DIN. Talk to experts, figure out the size and pressure you need, and that'll help you make the right choice.