When it comes to electronic manufacturing, the choice of a PCB assembly partner plays a pivotal role in the success of your projects. For businesses in Indiana seeking reliable PCB assembly services, finding the right partner is not only a matter of convenience but a critical decision that impacts the quality, efficiency, and ultimately the success of the final product. Now, we will delve into the key considerations that businesses should keep in mind when selecting a PCB assembly in Indiana.

Expertise and Experience:

The first and foremost consideration is the expertise and experience of the PCB assembly partner. Look for companies in Indiana that have a proven track record in the industry, with a portfolio that showcases successful projects and a depth of experience that aligns with your specific requirements.

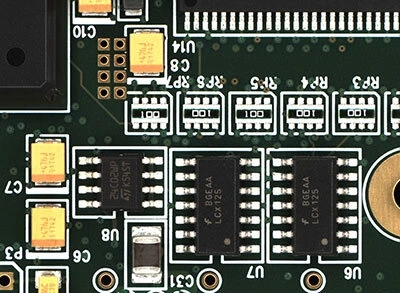

Technology and Equipment:

State-of-the-art technology and advanced equipment are crucial for efficient and high-quality PCB assembly. Explore the capabilities of potential partners in Indiana, ensuring that they are equipped with the latest tools and technologies to meet the evolving demands of electronic manufacturing.

Quality Standards and Certifications:

Quality is non-negotiable in electronic manufacturing. Verify that the PCB assembly partner in Indiana adheres to industry standards and holds relevant certifications. Compliance with standards ensures that your products meet the required specifications and regulations.

Turnaround Time:

Time-to-market is a critical factor in today's fast-paced business environment. Assess the turnaround time offered by the PCB assembly partner. A reliable partner in Indiana should be able to deliver within reasonable timelines without compromising on quality.

Flexibility and Scalability:

Consider the flexibility and scalability of the PCB assembly partner. As your business grows, your manufacturing needs may change. An adaptable partner in Indiana can accommodate these changes seamlessly, ensuring a long-term and fruitful collaboration.

Supply Chain Management:

Efficient supply chain management is essential for uninterrupted production. Evaluate how the PCB assembly partner in Indiana manages its supply chain, including sourcing of components and handling any potential disruptions.

Communication and Collaboration:

Effective communication is the foundation of a successful partnership. Choose a PCB assembly partner in Indiana that values clear and transparent communication, fostering a collaborative relationship that enhances the overall project outcome.

Cost Considerations:

While cost should not be the sole determining factor, it is undeniably an important consideration. Evaluate the pricing structure of potential partners in Indiana, ensuring that it aligns with your budget without compromising on quality.

Conclusion:

Choosing the right PCB assembly partner in Indiana is a decision that requires careful consideration of various factors. By prioritizing expertise, technology, quality, and other key considerations, businesses can establish a strong partnership that contributes to the success and growth of their electronic manufacturing endeavors. Remember, the right partner not only assembles PCBs but also adds value to your entire supply chain and product development process.