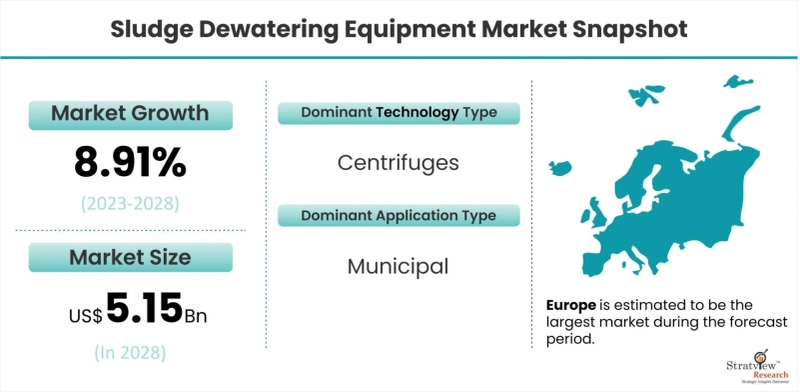

According to Stratview Research, the sludge dewatering equipment market was estimated at USD 3.07 billion in 2022 and is likely to grow at a CAGR of 8.91% during 2023-2028 to reach USD 5.15 billion in 2028.

Efficient sludge management is essential for industries and municipalities to meet environmental regulations, reduce disposal costs, and minimize their environmental footprint. A critical component of this process is choosing the right sludge dewatering equipment. With a plethora of options available, selecting the most suitable equipment can be a complex task. In this comprehensive guide, we will outline key factors to consider when choosing the right sludge dewatering equipment.

Understand Your Sludge:The first step in selecting the right equipment is to understand the characteristics of your sludge. Sludge can vary significantly in composition, including its solids content, particle size, and chemical makeup. Consider whether your sludge is primary or secondary, biological or chemical, as these factors will influence your equipment choice.

Dewatering Method:There are several methods for dewatering sludge, each with its advantages and limitations. Common methods include belt filter presses, centrifuges, screw presses, and filter presses. Research and compare these methods to determine which is best suited for your specific sludge type and treatment goals.

Capacity and Throughput:Assess the volume of sludge your facility generates on a daily or hourly basis. Your equipment choice should be capable of handling the required throughput efficiently. Oversized equipment can be costly and energy-inefficient, while undersized equipment may lead to process bottlenecks.

Required Dryness or Cake Solids:The dryness or cake solids content you need to achieve is a critical parameter. Different equipment types excel at producing different levels of dryness. Determine your target dryness level and choose equipment that can consistently meet these requirements.

Energy Efficiency:Energy consumption is a significant operating cost for sludge dewatering equipment. Look for equipment models that are energy-efficient and incorporate features like variable speed drives, automatic controls, and energy recovery systems to minimize operational expenses.

Maintenance and Operational Costs:Consider the maintenance requirements and associated costs of your chosen equipment. Some equipment may require more frequent maintenance and replacement of wear parts, impacting long-term operating costs. Factor in the cost of spare parts and servicing when making your decision.

Footprint and Space Constraints:The physical footprint of the equipment is essential, especially if you have limited space available. Choose equipment that fits within your facility's spatial constraints while still allowing for easy access for maintenance.

Environmental Considerations:Evaluate the environmental impact of your equipment choice. Some dewatering methods may produce higher volumes of waste or require more chemicals, which can affect your sustainability goals. Opt for equipment that aligns with your environmental objectives.

Regulatory Compliance:Ensure that the chosen equipment complies with relevant environmental and safety regulations. Compliance is crucial to avoid fines and legal issues associated with sludge management.

Cost-Benefit Analysis:Perform a thorough cost-benefit analysis to assess the overall economic feasibility of your equipment choice. Consider both the initial capital investment and ongoing operational costs, as well as any potential savings from reduced disposal fees and resource recovery.

Consult with Experts:When in doubt, seek advice from experts or consultants with experience in sludge dewatering. They can provide valuable insights into the specific challenges and opportunities related to your sludge management needs.

In conclusion, choosing the right sludge dewatering equipment is a crucial decision that can significantly impact your facility's operational efficiency, compliance with regulations, and bottom line. By understanding your sludge characteristics, treatment goals, and the factors mentioned above, you can make an informed choice that ensures effective sludge management while minimizing costs and environmental impact. Remember that selecting the right equipment may require careful research and consultation with experts in the field, but the benefits of improved sludge dewatering are well worth the effort.