Plasma is a state of matter distinct from solid, liquid, or gas and is a component in fusion reactors. Plasma technology is a popular source for converting solid to liquid and liquid to gas in modern industry. The process includes heating up the gas until all the atoms lose their electrons and leave a highly electrified collection of nuclei and free electrons. The purpose of plasma technology in one industrial unit may differ from another, and it is substantive in manufacturing. This article discusses a breakdown of plasma applications and their benefits.

Plasma cleaning

For a business that involves maintenance and processing, a cleaning system is essential for washing and cleaning equipment parts regularly. After a process that generates waste materials, the residue could stay in the machine and cause disruption. A clean component ensures equipment optimizes productivity rates by maintaining its functionality. Plasma-enhanced chemical vapor deposition can clean unwanted substances from the surface of plastic, metal, and other materials. Plasma treatment can remove particles that could develop molds and stubborn stains.

Metal treatment

A rusted part may cause disruption to the function of the whole machine, causing downtime and creating a huge loss to the business. When a metal object collects rust after exposing to humidity or water in the processing, there is a risk of developing corrosion on its surface. At the same time, applying traditional paints on the material is not an option to reduce the deterioration. Implementing plasma treatment on the metal is the best approach to save the material from quick corrosion.

Adhesion assistance

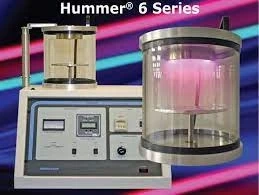

In a manufacturing unit that involves bonding and joining two different sections of a part, there is a need for an agent to bond them. When another technic, such as bolting with nuts and screws, is impossible, plasma technology can complete the complicated task. Adding plasma heating to the adhesion work can expand the surface and reach its hummer sputter targets. The dissolving of the substance prevents abrasion, dents, and smudges while conjoining through fluidity without leaving a mark on the surface.

Dyeing fabrics

It is not easy to apply traditional ink on the textile material, especially when the processing unit is dealing with bulk orders. The liquid for coloring may not blend with the fabric due to its unsuitable capillarity. If putting excess ink to absorb into the layers can ruin the cloth, increasing the adhesiveness with plasma treating is the method to color threads, yearns, and textile layers regardless of the material type. Cotton, wool, silk, polyester, and other synthetic resins can rely on plasma treatment.

Packaging

The packaging industry includes different segments of the procedure to pack, label, and store particular products in warehousing units. Some materials for packing are easy to fold and stick to one another when packing them. However, many packaging materials require unique processes to improve adhesion and flexibility by applying plasma. The technic allows materials to fold into appropriate shapes by heating and gluing them together. To enhance the sputtering system in the facility, enterprises should get plasma system repair and upgrade programs.

If you own a business relying on automated machines for binding and cleaning, find a company that provides plasma treatment for quality and high production rates.