You might be familiar with a sentence Grinding is a black art. It doesn’t matter that you have the latest equipment and you keep lubricating wheels and other parts at your production unit. However, it matters a lot if you are careful while executing several jobs to get the expected results. Advancements in technology and manufacturing procedures have changed a lot. Due to this, grinding hasn’t been a tricky job now. However, there is a need for smart planning and studies to avoid errors and get high-grade finished products.

As grinding is the last step of a product production so unplanned grinding can influence other jobs at the production floor. You need to take proper care of this process. Here are some steps that can facilitate the grinding operation:

Embrace Grinding Wheels and Cylindrical Grinding

Begin with the wheel. The perplexing range of grit sizes, grain structures, abrasive & bond types, and hardness grades available in the catalogue or wheel manufacturer’s site is not for marketing. You need an array of grinding wheel options if you will grind several types of materials at distinguished hardness levels. Keep in mind there is nothing as general with grinding wheels.

Opt for cylindrical grinding. People who are engaged in manufacturing gears, shafts, impellers, and spins are familiar with it. Smart machining shops involved in grinding parts at their in-house units have an excellent control over delivery and prices on the use of sophisticated technology. You must contact an expert if you have no in-house grinding facility.

Keep the operation cool

Keep lubricating your CNC Grinding Machine. For this, you can utilize neat oil that is lubricious and reduces heat and friction between equipment and parts being grinded. This fluid does a harmful job by removing the left heat and can influence the accuracy of parts badly. To avoid this, you should apply water-soluble fluid for lubrication purposes. With this, you can keep your tools and equipment pieces at your shop cool.

Keep tracking your operation at the production unit

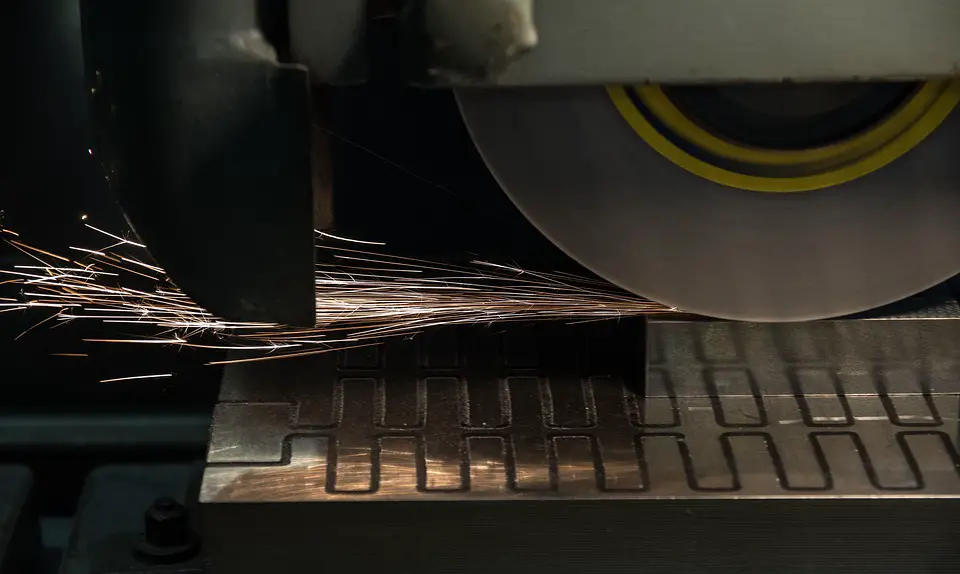

As documentation helps you stay safe so the technology does with the tracking. Each point you read in the user manual applies equally to internal grinding, centerless, and surface. To comprehend it better, suppose that your grinding fluid is clean and a perfect wheel. Try to answer the queries like proper infeed amount, occurrence of traverse, surface speed for material as well as grinding wheel and sparking time.

You should document while resolving the related queries. With this, you can quickly and easily comprehend what’s going on at your production unit while executing grinding jobs. Your tracking of the final operating parameters of a job like what you tried, what worked well, and what didn’t work for your grinding job is critical for your manufacturing business. If you have any confusion on its operation, consult the manufacturer of CNC Grinding Machine and follow what they instruct you on how to execute your grinding operation.

Conclusion

Executing the grinding process well is vital if you are serious about enhancing your operation. Whether it is opting for an appropriate method, keeping machines cool, and tracking the operation, you must be ready to take every possible step. Your utmost care and wise decision on operating machine will help you attain the maximum output.