Can a single-chip microcomputer replace a PLC? This question is like flour can replace noodles. The answer is no. When hearing this answer for the first time, many people may have doubts. Why can't the MCU replace the PLC because it has such powerful functions and rich functions?

1. Single chip microcomputer

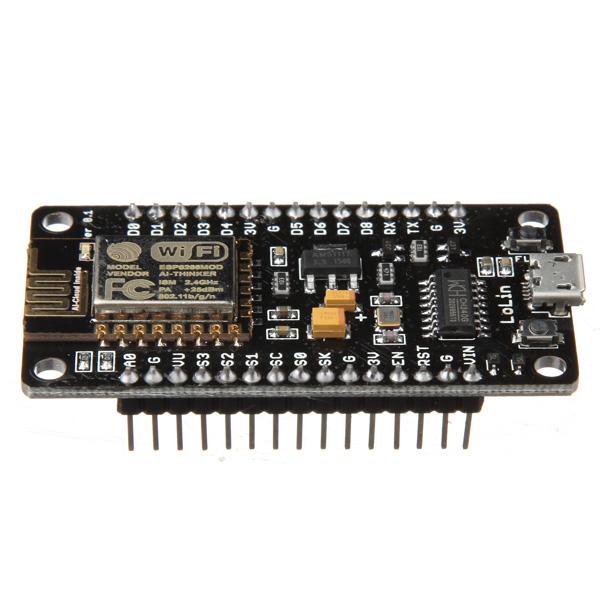

Single Chip Microcomputer, also known as Microcontroller Unit, abbreviated as MCU, is a kind of integrated circuit chip, which uses VLSI technology to integrate the Central Process Unit with data processing capabilities, random access memory (RAM), read-only memory (ROM), multiple I/O ports and interrupt systems, timers/counters and other functions (may also include display drive circuits, Pulse width modulation circuit, analog multiplexer, A/D converter and other circuits) are integrated on a silicon chip to form a small and complete microcomputer system, which is widely used in various fields. Such as mobile phones, PC peripherals, remote controls, to automotive electronics, industrial stepping motors, robotic arm control, etc., you can see the MCU.

2. PLC

PLC, the full name Programmable Logic Controller, is a programmable logic controller, which is a digital operation electronic system specially designed for application in an industrial environment. It uses a programmable memory to store instructions for performing logic operations, sequence control, timing, counting and arithmetic operations, and control various types of mechanical equipment or production through digital or analog input and output. process.

3. Why can't the single-chip microcomputer replace the PLC?

1) Stability and reliability

Some people say that this is a false problem. The single-chip microcomputer is a component, and the PLC is a system composed of components and huge software. The two are not comparable in this respect. This is not wrong. Most PLC control chips are actually single-chip microcomputers. In other words, PLC can be regarded as the secondary development of single-chip microcomputers. In terms of industrial protection level, the stability and reliability of single-chip microcomputers cannot be compared with PLC IP67.

2) I/O function

The I/O points of the single-chip microcomputer are really limited, but what about the PLC? For different field signals, there are corresponding I/O points that can be directly connected to industrial field devices (such as buttons, switches, sensor current transmitters, motor starters or control valves, etc.), and are connected to the CPU main board through the bus connection. Almost any production line in the industry has hundreds or even thousands of I/O points, which is completely unmatched by single-chip microcomputers.

3) Extended functions

In addition to control, a complete industrial production line also has communication, host, configuration, motion control and display, etc., all of which need to rely on a complete industrial system and communication protocol, such as Siemens’ PROFIBUS-DP communication, Mitsubishi Heavy Industries CC-LINK and so on. The communication between MCU and PC, MCU and MCU mostly use serial port.

4) Development Cycle

There are more than 200 PLC brands. Almost every brand has different programming software, and they are constantly improving their own programming software to make it easier and simpler to serve electrical engineers, and various program blocks are also increasing. The more convenient and humanized it is to call arbitrarily, such as PID module, motion control module, etc., which greatly reduces the development pressure of engineers and shortens the development cycle. How to realize the microcontroller? If there is no ready-made module to use, it can only be developed. Then engineers who have done non-standard automation equipment will encounter a problem-insufficient construction period.

5) Communication distance

At present, most of the pipelines are to be integrated and monitored across regions. The communication methods used are mostly Ethernet plus repeaters, or direct civilian broadband optical fibers. In the end, the things used are likely to be Microsoft's IE browser. Obviously PLC has an RJ-45 interface. Even if the body does not have an RJ-45, it can be equipped with an Ethernet module. Can the PCB board of the microcontroller add this interface and then develop Ethernet communication? How long does it take to develop?

6) Programming language

This is an advantage for the microcontroller, but also a disadvantage. As mentioned above, there are more than two hundred PLC brands and more programming software. Although the programming languages of most PLCs are the same, the electrical engineer must learn from the hardware parameters, software components, and components of the PLC every time they come into contact with a PLC of a different brand. It's handy to understand all aspects of programming software and so on from the beginning to use. The programming language of the single-chip microcomputer is C language or assembly language, which is common to any single-chip microcomputer.

4. Conclusion

After the above explanation, we can see that PLC can actually be regarded as the secondary application development of single-chip microcomputer, but it has its own distinct characteristics. So far, China’s single-chip application and embedded system development has gone through more than 20 years of development in various fields such as national economic construction, military and household appliances, especially mobile phones, auto navigation equipment, PDAs, smart toys, and smart devices. Industries such as home appliances and medical equipment are all using single-chip microcomputers. There are currently more than 100,000 engineers engaged in the development and application of single-chip microcomputers.