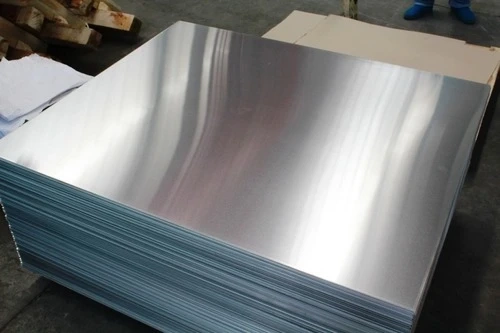

When choosing stainless steel sheets, one must consider the environment in which they will be used. Usually, corrosion-resistant SS sheets are employed. Austenitic stainless steels have exceptional mechanical qualities and superior resistance to corrosion due to the large levels of nickel and chromium they contain. Numerous austenitic stainless sheets of steel can also be formed and joined. Austenitic stainless steel grades 304 and 316 are two of the most popular types.

About SS 304 Sheet Plate

The most popular austenitic stainless steel sheet is typically thought to be the stainless steel 304 sheet. It has a significant quantity of chromium—between 18 and 20 percent by weight—and nickel—typically between 8 and 10.5 percent by weight. Manganese, silicon, and carbon are some further important alloying components. Iron makes up the majority of the remaining chemical composition.

Even at cryogenic temperatures, which are considered to be very low temperatures, SS 304 Sheet Plate exhibit excellent toughness. The high chromium and nickel content in 304 stainless steel sheets provides outstanding corrosion resistance. In intermittent service up to 870 degrees C and in continuous service up to 925 degrees C, SS 304 Sheets exhibit good oxidation resistance.

About SS 316 Sheet Plate

Grade 316 stainless steel has comparable high chromium and nickel contents to grade 304 stainless steel. 316 is primarily composed of iron, with minor amounts of carbon, silicon, and manganese. The chemical composition of 304 and 316 stainless plates of steel differs significantly, with SS 316 often containing 2 to 3 percent by weight of molybdenum compared to barely trace quantities in 304.

The greater corrosion resistance of stainless steel 316 Sheet is due to the higher molybdenum content. When choosing an austenitic stainless steel sheet for nautical applications, the stainless steel 316 sheet is frequently regarded as one of the best options.

Which grade to choose?

The increased molybdenum content in SS Grade 316 Sheets can have negative impacts on formability, hence SS 304 Sheets can be employed if the application demands exceptional formability. In general, Grade 304 sheets cost less than Grade 316 sheets, so if cost is an issue, SS 304 sheet plate needs to be chosen.