CMMS software provides a systematic approach to maintenance management, enabling businesses to optimize their maintenance activities, reduce downtime, and extend the lifespan of their assets.

At its core, a CMMS serves as a comprehensive database that stores crucial information about an organization's assets, including equipment, machinery, facilities, and infrastructure. This database typically includes details such as equipment specifications, maintenance CMMS history, warranties, and manuals. By maintaining a centralized repository of asset information, CMMS software allows maintenance teams to quickly access relevant data, track asset performance, and make informed maintenance decisions.

One of the key features of CMMS software is its ability to facilitate preventive maintenance. Preventive maintenance involves scheduling routine inspections, servicing, and repairs to prevent equipment breakdowns and minimize unplanned downtime. With a CMMS, maintenance managers can create maintenance schedules based on factors such as asset usage, manufacturer recommendations, and regulatory requirements. The software sends automated notifications and work orders to maintenance technicians, ensuring that preventive maintenance tasks are completed on time and according to schedule.

In addition to preventive maintenance, CMMS software also supports corrective maintenance, which involves addressing unexpected equipment failures and breakdowns. When a maintenance issue arises, technicians can use the CMMS to report the problem, generate work orders, and track the status of repairs in real time. By streamlining the corrective maintenance process, CMMS software helps organizations minimize downtime, improve asset reliability, and reduce maintenance costs.

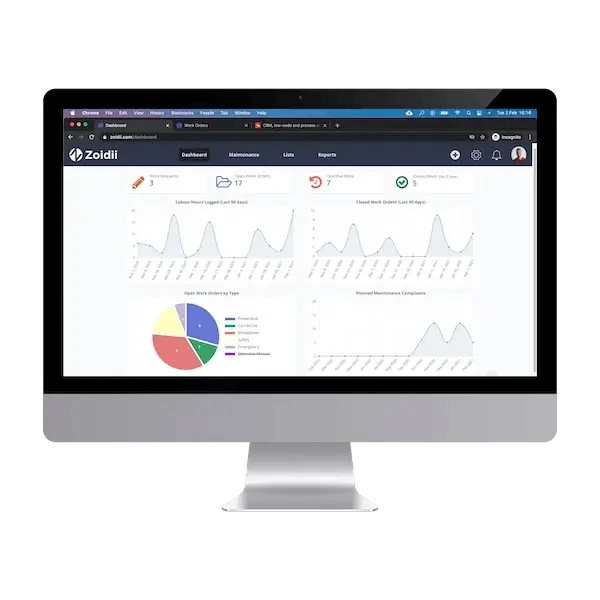

Furthermore, CMMS software offers advanced reporting and analytics capabilities that enable organizations to gain valuable insights into their maintenance operations. Maintenance managers can generate customizable reports on key performance metrics such as equipment uptime, maintenance costs, and work order completion rates. By analyzing this data, organizations can identify trends, pinpoint areas for improvement, and optimize their maintenance strategies for greater efficiency and effectiveness.

Another benefit of CMMS software is its integration with other business systems and technologies. CMMS systems can often integrate with enterprise resource planning (ERP) systems, asset management software, and Internet of Things (IoT) devices to provide a seamless flow of information across the organization. This integration enables organizations to automate data exchange, improve collaboration between departments, and enhance overall operational efficiency.