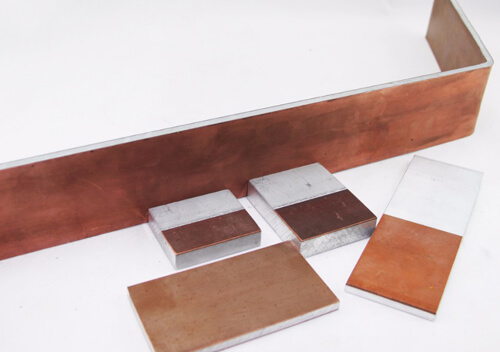

Copper Laminated Busbars contain adaptable covered copper associations that are delivered utilizing profoundly conductive electrolytic review copper thwart and sheets. These overlaid Busbars experience squeeze welding where singular copper strips are combined through applying direct present and additionally weight, which brings about guaranteeing least resistance and also in improving the item life and in addition in the lessening of downtime.

Further, these likewise highlight predominant mechanical and electrical properties at higher temperatures. These component higher power thickness and additionally better electromagnetic similarity (EMC).

General Properties:

- • Size -lengths up to 1000mm

- • Thickness – = 1,6 mm. = 2 mm

- • Weight – Weight per feet in kg

- • Standard & Material -ASTM D150 ASTM D149

Application Areas:

- • Custom Power Distribution Assemblies

- • Multi-Layer Laminated Copper Connectors

- • Multi-Layer Bus Bars

- • Capacitor and IGBT Structures

Laminated bus bar also meets the needs of industries like:

- • Telecom

- • Power Generation

- • Electromechanical Motor Controls

- • Aerospace applications

- • Military applications

0

ince our establishment way back in the year 1990. We - Chhajed Steel & Alloys Pvt Ltd. An ISO 9001 : 2015, ISO 14001 : 2015, OHSAS 18001:2007 certified are manufacturing and exporting a comprehensive range of electrolytic & copper in the form of strips, wires, flats, rods, section, pipes & tubes. Our product range includes bus bar (heavy type), flexible bus bar - type I, strips, rods & pipes, copper wire, bus bars & flats, flexible connectors, bus bar assemblies, flat copper wire, winding strips & wires of copper, forged copper clamp and flexible bus bar - type II. These precision engineered products are widely used in several industrial and commercial projects. We have earned the reputation of dependable supplier among a large client base in global marketplace. This position is earned due to our consistency in product's quality and timely services offered to the clients. For effective production, we have our own manufacturing facilities located in Daman which is ZERO tax Zone Products Our range of products includes bus bar (heavy type), flexible bus bar - type I, strips, rods & pipes, copper wire, bus bars & flats, flexible connectors, bus bar assemblies, flat copper wire, winding strips & wires of copper, forged copper clamp and flexible bus bar - type II. • Copper Bars • Copper Rods • Copper Tape and Foil • Copper Pipes & Tubes • Flexible Copper Products • Other Copper Products • Brass Bars • Brass Rods

https://chhajedcopperbrass.com/