Corrugated plastic sheets are innovative materials known for their durability, strength, and versatility. These lightweight yet robust sheets feature a distinctive corrugated design that enhances structural integrity and provides numerous benefits across various industries. In this comprehensive guide, we\'ll delve into the advantages, types, applications, and design features of corrugated plastic sheets, offering insights into their wide-ranging uses and benefits.

Advantages of Corrugated Plastic Sheets

Durability and Strength

Corrugated plastic sheets are renowned for their exceptional durability and strength, making them ideal for demanding applications that require long-lasting performance. Unlike traditional materials such as cardboard or wood, corrugated plastic sheets resist moisture, chemicals, and impact damage, ensuring reliable protection for packaged goods and construction projects.

Lightweight and Easy to Handle

Despite their robust construction, corrugated plastic sheets are lightweight and easy to handle, making them convenient for packaging, transportation, and installation. Their lightweight nature reduces shipping costs and labor requirements while facilitating quick and efficient handling in various settings.

Versatility and Flexibility

Corrugated plastic sheets offer unparalleled versatility and flexibility, allowing for a wide range of applications across diverse industries. From packaging and signage to construction and agriculture, these sheets can be customized to meet specific requirements and tailored to fit unique project needs.

Types of Corrugated Plastic Sheets

Polypropylene Corrugated Sheets

Polypropylene corrugated sheets are popular choices for packaging, signage, and construction applications due to their lightweight yet durable properties. These sheets offer excellent resistance to moisture, chemicals, and weathering, making them suitable for both indoor and outdoor use.

PVC Corrugated Sheets

PVC corrugated sheets are widely used in signage, advertising, and construction projects due to their rigidity, impact resistance, and printable surface. These sheets provide exceptional durability and visual appeal, making them ideal for applications that require high-quality graphics and long-lasting performance.

Comparison of Materials

Polypropylene and PVC corrugated sheets offer distinct advantages and characteristics that cater to different needs and preferences. While polypropylene sheets excel in terms of lightweight design and chemical resistance, PVC sheets offer superior rigidity and printability for visually impactful applications.

Applications

Packaging and Shipping

Corrugated plastic sheets are commonly used for packaging and shipping due to their lightweight, durable, and protective properties. These sheets provide cushioning and support for fragile items, ensuring safe transit and delivery while reducing the risk of damage during handling and transportation.

Signage and Advertising

In the signage and advertising industry, corrugated plastic sheets serve as versatile substrates for indoor and outdoor displays, banners, and promotional signage. Their smooth, printable surface allows for vibrant graphics and crisp imagery, making them effective marketing tools for businesses and organizations.

Construction and Building

In the construction and building sector, corrugated plastic sheets find applications in roofing, cladding, and temporary structures. Their lightweight design, weather resistance, and ease of installation make them ideal for roofing projects, temporary barriers, and protective coverings during construction activities.

Design Features

Corrugation Patterns

Corrugated plastic sheets feature distinctive corrugation patterns that enhance structural strength and rigidity. Common patterns include square wave, sine wave, and trapezoidal profiles, each offering unique performance characteristics and aesthetic appeal for different applications.

UV Stabilization

UV stabilization additives are often incorporated into corrugated plastic sheets to enhance weather resistance and prolong colorfastness. UV-stabilized sheets maintain their appearance and performance in outdoor environments, resisting fading, discoloration, and degradation from prolonged sun exposure.

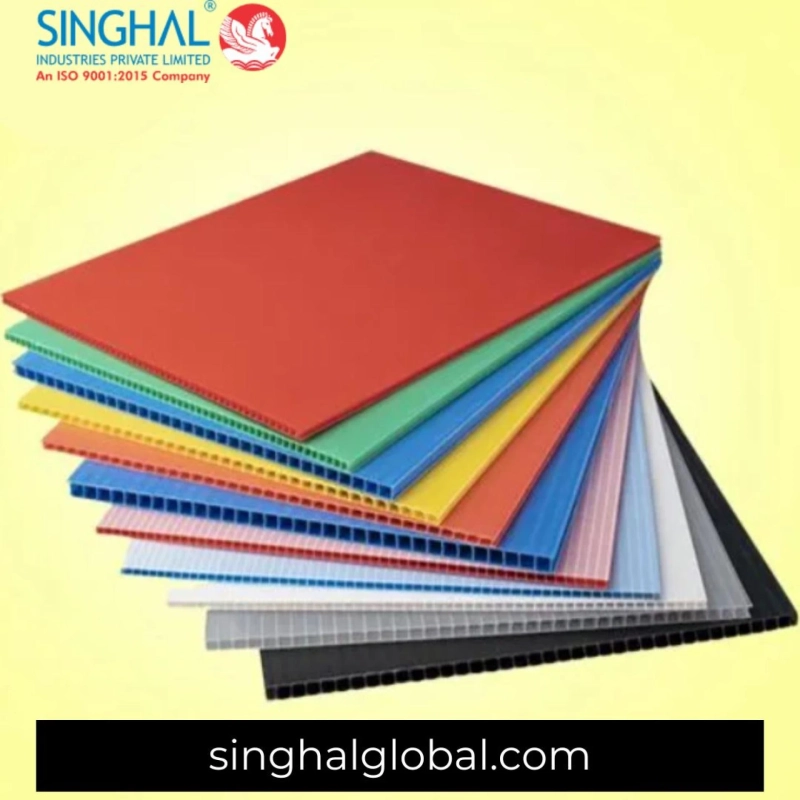

Color Options and Printing Capabilities

Corrugated plastic sheets are available in a wide range of colors and finishes to suit diverse aesthetic preferences and branding requirements. Additionally, these sheets offer excellent printing capabilities, allowing for custom graphics, logos, and messaging to be applied directly onto the surface for promotional or informational purposes.

Factors to Consider

Thickness and Strength

Consider the thickness and strength requirements when selecting corrugated plastic sheets for specific applications. Thicker sheets offer increased durability and load-bearing capacity, making them suitable for heavy-duty packaging and structural applications.

Environmental Impact

Evaluate the environmental impact of corrugated plastic sheets, including their recyclability, biodegradability, and sustainability credentials. Opt for sheets made from recycled materials or eco-friendly alternatives to minimize waste and reduce environmental footprint.

Cost-Effectiveness

Balance cost considerations with performance requirements when choosing Best plastic corrugated sheet for projects. While initial costs may vary depending on material quality and specifications, selecting high-quality sheets that offer long-term durability and reliability can result in cost savings over time.

Maintenance Tips

Cleaning and Storage

Maintain the cleanliness of corrugated plastic sheets by regularly cleaning them with mild soap and water to remove dirt, debris, and stains. Store sheets in a dry, ventilated area away from direct sunlight and extreme temperatures to prevent warping or damage.

Repair and Maintenance

Repair minor damage to corrugated plastic sheets using adhesive patches or sealants to reinforce damaged areas and prevent further deterioration. Inspect sheets regularly for signs of wear or damage and address any issues promptly to prolong their lifespan and performance.

Conclusion

In conclusion, corrugated plastic sheets offer a versatile and cost-effective solution for a wide range of applications across industries. With their durability, strength, and flexibility, these sheets provide essential protection, packaging, and structural support in diverse settings. By considering factors such as material type, design features, and maintenance requirements, businesses and consumers can harness the full potential of corrugated plastic sheets for their projects and initiatives.

FAQs

Can corrugated plastic sheets be recycled?

Yes, corrugated plastic sheets are recyclable materials that can be processed and reused to create new products. Recycling facilities accept corrugated plastic sheets for recycling, helping to reduce waste and conserve valuable resources.

Are corrugated plastic sheets waterproof?

Yes, corrugated plastic sheets are waterproof materials that resist moisture, making them suitable for outdoor applications and environments with high humidity or rainfall. These sheets provide effective protection against water damage and maintain their structural integrity in wet conditions.

How do I cut corrugated plastic sheets?

To cut corrugated plastic sheets, use a sharp utility knife or scissors to score along the desired cutting line. Then, carefully bend the sheet along the scored line to create a clean, precise cut. Alternatively, use a power saw with a fine-tooth blade for larger or thicker sheets.