Plastic injection moulding is a common process for manufacturing goods and products on a large scale. It is quick and can be customized in any way you are looking for. Many plastic manufacturing companies reach out to factories that provide these services and help the companies in customizing and manufacturing the products of their liking or choice. So, in this way, the product your company produces can be easily manufactured by having a tie-up with the factories that provide these services.

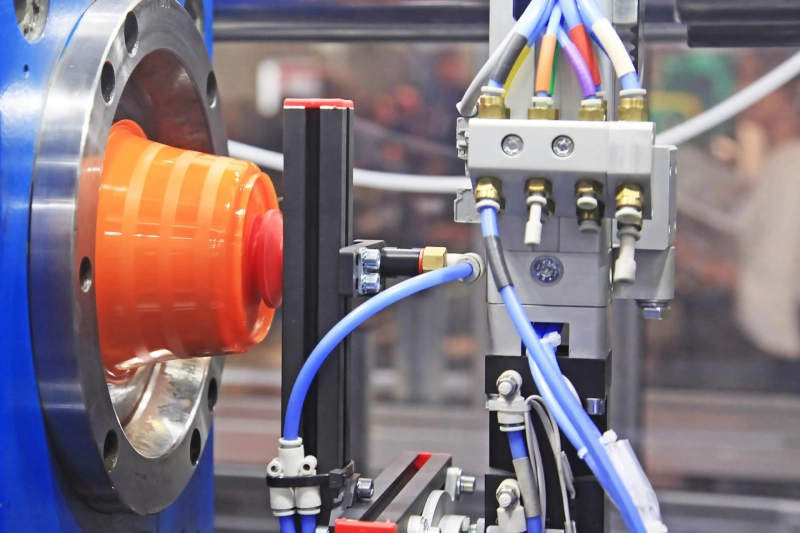

What is plastic injection moulding?Injection moulding is the way toward utilizing plastic to make a wide scope of parts and items. The infusion forming machine utilizes handcrafted moulds to round them out as indicated by particulars, making indistinguishable duplicates that can be redone in an assortment of ways. What’s more, injection moulding is an adaptable cycle, taking into account a wide scope of various materials and completions, which makes it a well-known alternative in endless ventures with totally various objectives and requirements.

Because of this adaptability, the injection moulding machine fabricating is even utilized for the absolute most in-demand products in the world, creating parts in aviation, clinical fields, and the automobile industry. Whether you're hoping to deliver few sections for testing, or need a dependable technique for delivering huge amounts of parts in a rush, infusion trim can be an ideal decision, particularly when working with plastics. What’s more, the one of a kind cycle when assembling part with an infusion shaping machine likewise implies that you can deliver complex parts with unpredictable plans, which isn't something that can be said to pretty much all assembling choices out there.The capacity to make enormous amounts of parts at a reasonable expense additionally makes it undeniably appropriate for the creation of different wares. Indeed, almost certainly, many of the family things that you have might have been delivered utilizing injection moulding.

How will the process of custom plastic moulding work for you?Custom formed thermoplastics are created in nurdles, small pellets of plastic expected to make transport simpler for trade. When the nurdles are utilized by a maker to create a plastic application, they are dissolved together to frame a liquid shower, moulded into the last structure and afterwards restored, or dried. When the thing is relieved, it is in its last shape. Metals, then again, are regularly sent as stock, including bar stock, pipe stock, and metal poles. Stock is a type of formed crude metal that comes in unpredictable sizes. It is shipped to producers so they can dissolve the metal down and use it for different purposes, including further delivery or last assembling. Different kinds of metals, including many utilized for certain embellishment activities, are sent as powders that can be warmed into a liquid structure.

Most moulding methods require the utilization of a releasing specialist. A releasing agent is a kind of grease that decreases the odds of a formed material adhering to the inside surface of the mould.There are plastic mould manufacturers in china, that you can reach out to for easy customization of your products.