In the modern manufacturing landscape, precision is everything. One small misalignment can derail production schedules, compromise product quality, and inflate costs. This is where CMM Fixtures come into play. They ensure accurate measurements, reduce human error, and optimise workflow efficiency. But designing these fixtures isn’t just about accuracy—it’s about balancing precision with practicality. In this blog, we explore how businesses can master this balance and why investing time in thoughtful design pays dividends.

The Role of CMM Fixtures in Manufacturing

A Coordinate Measuring Machine (CMM) is a cornerstone in quality control. It measures the geometry of physical objects with extreme accuracy, using a probe to collect data points. However, without a reliable fixture, even the most advanced CMM can produce inconsistent results.

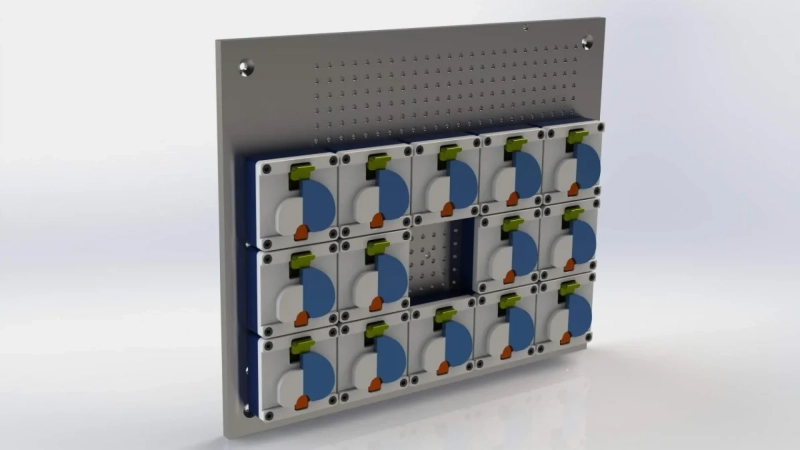

CMM Fixtures hold parts securely during measurement, ensuring repeatability and reducing variability. Think of them as the unsung heroes that prevent parts from shifting, warping, or vibrating during inspections. The right fixture translates into faster inspections, higher throughput, and fewer rejected components—essential in industries like aerospace, automotive, and precision engineering, where tolerances can be as tight as 0.01mm.

Why Balancing Precision and Practicality Matters

It’s tempting to over-engineer CMM Fixtures, adding every possible clamp, support, or alignment feature. But this can backfire. Overly complex fixtures are expensive, hard to maintain, and time-consuming to set up. On the other hand, overly simple fixtures may compromise measurement accuracy.

The sweet spot lies in designing fixtures that are precise, durable, and easy to use. According to a 2023 report by IndustryWeek, companies that invested in optimised fixturing solutions reported a 35% reduction in measurement time and a 22% decrease in defective parts. That’s not just a number—it’s efficiency and quality translating directly into cost savings and improved customer satisfaction.

Key Principles in Designing Effective CMM Fixtures

Designing effective CMM Fixtures requires a blend of engineering expertise, material knowledge, and practical insight. Here are some guiding principles:

Repeatability First: Your fixture should position the part identically each time. Even tiny deviations can skew measurement results.

Material Matters: Aluminium is lightweight but less rigid, while steel offers strength at the cost of weight. The choice depends on the part and inspection requirements.

Ease of Use: A fixture that takes hours to set up negates the efficiency of using a CMM. Quick-release clamps and modular components can save significant time.

It’s also essential to consider how your fixture integrates with existing jigs and fixtures on the shop floor. Standardising fixturing elements reduces training requirements and simplifies inventory management.

Avoiding Common Pitfalls

Even experienced engineers can fall into traps when designing CMM fixtures. One common mistake is ignoring thermal expansion. Materials expand and contract with temperature, which can subtly affect measurements. Another is overcomplicating clamping mechanisms—more parts mean more potential points of failure.

Furthermore, fixture designers sometimes underestimate the human factor. Operators need intuitive setups. If a fixture is confusing or fiddly, errors creep in. A fixture that prioritises operator experience alongside measurement accuracy often delivers the best results.

Integrating Jigs and Fixtures with CMM Systems

Jigs and Fixtures are traditionally associated with manufacturing processes like drilling, milling, and assembly. However, their principles are equally vital in metrology. By integrating CMM-specific fixtures with existing jigs and fixtures, companies create a cohesive system where production and inspection flow seamlessly.

For example, modular fixtures that can transition from CNC machines to CMMs minimise handling, reduce part wear, and enhance measurement consistency. This synergy not only saves time but also enhances product reliability—a critical differentiator in high-stakes industries.

Real-World Impact

Consider a precision engineering firm producing aerospace components. Before optimising their CMM Fixtures, inspection cycles were slow, and errors in alignment led to occasional scrapped parts. After redesigning their fixtures with practicality in mind—using lightweight aluminium frames, quick-release clamps, and standardised locators—they reduced inspection time by 40% and virtually eliminated setup errors.

This is more than efficiency; it’s a competitive edge. In industries where precision is non-negotiable, the right fixture design can mean the difference between winning contracts and missing deadlines.

Tips for Businesses Investing in CMM Fixture Design

1. Engage Experienced Designers: Fixture design is both art and science. Experienced engineers anticipate practical challenges that automated systems cannot detect.

2. Standardise Where Possible: Standard components simplify maintenance and reduce lead times for replacements.

3. Test Early and Often: Prototype fixtures and conduct trial inspections to identify unforeseen issues before full-scale deployment.

Additionally, adopting digital tools like CAD modelling and simulation software can predict how fixtures perform under real-world conditions. This reduces the risk of costly redesigns and ensures that your fixture balances precision with practicality from the outset.

The Future of CMM Fixtures

Innovation in fixturing is accelerating. Modular systems, lightweight composites, and automated clamping solutions are becoming more common. Smart fixtures equipped with sensors can even detect misalignment or wear in real-time, alerting operators before errors occur.

As manufacturing trends shift toward Industry 4.0, the interplay between precision measurement and practical fixturing will only grow. Companies that embrace this balance will not only enhance product quality but also streamline operations and improve workforce efficiency.

Conclusion: The Art of Balance

Designing CMM Fixtures is about more than mechanical design—it’s about harmonising accuracy with usability, cost, and workflow integration. When executed thoughtfully, fixture design enhances measurement precision, reduces waste, and drives operational excellence.

By understanding the principles of good fixture design, integrating with existing jigs and fixtures, and leveraging modern technology, manufacturers can achieve a perfect equilibrium: precision without impracticality. In today’s competitive market, that balance is not optional—it’s essential.