Introduction:

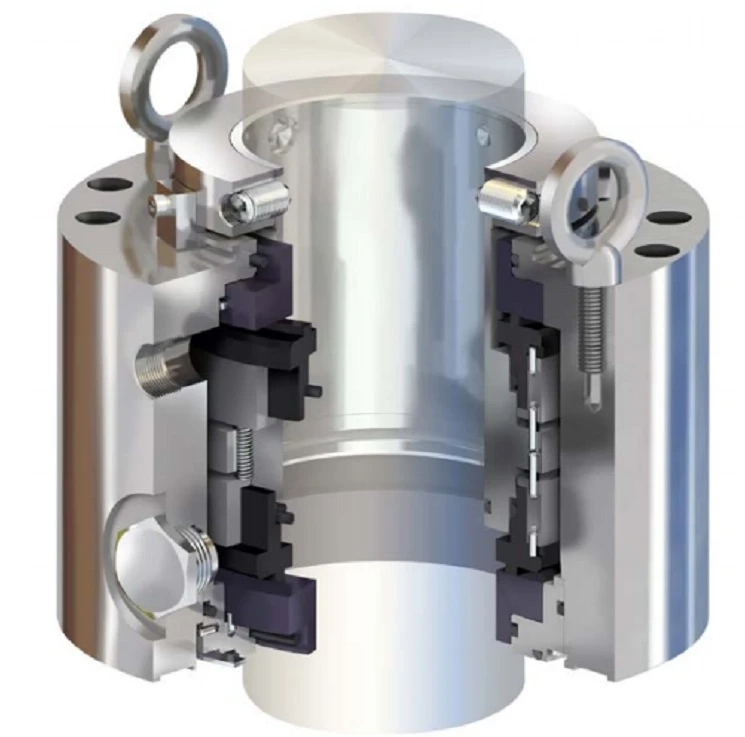

Mixer seals play a crucial role in various industries where efficient and reliable mixing operations are essential. These seals are designed to prevent leakage and contamination in mixing equipment, ensuring optimal performance and process integrity. This article explores the significance of mixer seals, their benefits, and their applications in different industries.

Importance of Mixer Seals:

Mixer seals are critical components that provide a secure sealing solution for mixing equipment. They prevent leaks, maintain product quality, and protect the integrity of the process. By containing fluids and preventing contamination, mixer seals contribute to efficient and reliable mixing operations.

Superior Sealing Performance:

Mixer seals offer superior sealing performance, even under challenging conditions such as high pressures, aggressive chemicals, and extreme temperatures. They are engineered with precision and designed to withstand the demanding environments encountered in various industrial applications.

Reduced Downtime and Maintenance Costs:

Efficient mixer seals help minimize downtime and maintenance costs. By preventing leaks and minimizing the risk of equipment failure, these seals contribute to uninterrupted mixing processes, reducing the need for costly repairs and ensuring smooth operations.

Versatility Across Industries:

Mixer seals find applications in diverse industries, including chemical processing, pharmaceuticals, food and beverage, and wastewater treatment. Their versatility allows them to be used in different types of mixers, including agitators, blenders, and reactors.

Customized Solutions:

Mixer seals can be customized to meet specific requirements, considering factors such as operating conditions, mixer design, and fluid compatibility. Customization options include selecting the right materials, seal face configurations, and auxiliary features to optimize sealing performance and longevity.

Mixer seals play a crucial role in ensuring efficient and reliable mixing operations across various industries. With their superior sealing performance, customization options, and versatility, these seals contribute to the integrity of the process, minimize downtime, and reduce maintenance costs. By choosing high-quality mixer seals, industries can achieve optimal mixing performance, maintain product quality, and enhance overall operational efficiency.