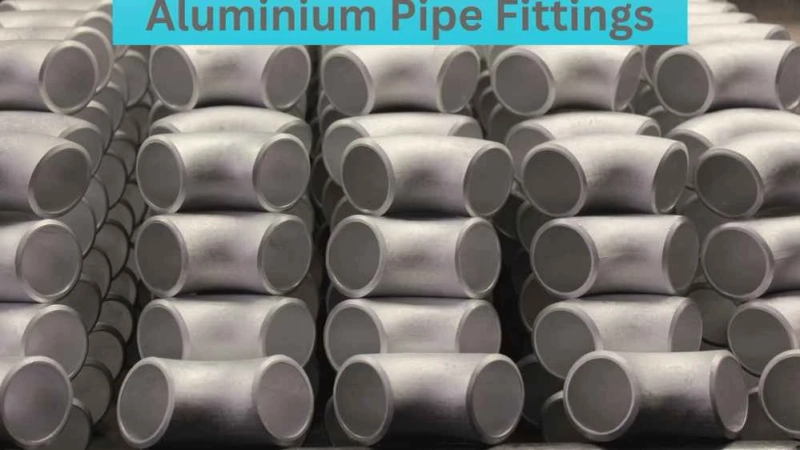

Aluminium pipe fittings are used in various industrial applications where lightweight, corrosion-resistant, and durable piping systems are required. Here is everything you need to know about aluminium pipe fittings:

Material:

Aluminium pipe fittings are made from aluminium, a lightweight metal known for its excellent corrosion resistance and high strength-to-weight ratio. Aluminium is widely used in various industries due to its versatility, durability, and low maintenance requirements.

Types of fittings:

Aluminium pipe fittings come in various styles, including elbows, tees, reducers, couplings, flanges, end caps, and more. These fittings connect aluminium pipes, tubes, or equipment in a piping system.

Benefits of aluminium pipe fittings: Aluminium pipe fittings offer several advantages, including:

Lightweight:

Aluminium is much lighter than other metals such as steel, making aluminium pipe fittings ideal for applications where weight is a concern, such as in aerospace, automotive, and marine industries.

Corrosion resistance:

Aluminium has a natural oxide layer that provides excellent corrosion resistance, making aluminium pipe fittings suitable for use in corrosive environments, including chemical processing and marine and offshore applications.

Durable:

Aluminium pipe fittings are known for their durability and can withstand harsh conditions, including extreme temperatures, high pressures, and corrosive environments, without degrading or losing their performance over time.

Low maintenance:

Aluminium pipe fittings require minimal maintenance, as they are resistant to rust, corrosion, and degradation, reducing the need for frequent inspections and repairs.

Versatility:

Aluminium pipe fittings can be used in various applications due to their versatility, including HVAC systems, compressed air systems, water supply systems, and more.

Installation:

Aluminium pipe fittings are typically joined using welding, brazing, or threaded connections, depending on the specific type of fitting and the application requirements. Proper installation techniques and tools should ensure a leak-free and reliable connection.

Standards:

Aluminium pipe fittings are manufactured according to various industry standards, such as ASTM, ASME, ANSI, DIN, and ISO, to ensure their quality, performance, and compatibility with other piping components.

Considerations:

When selecting aluminium pipe fittings for your application, consider factors such as the type of fluid or gas being transported, the operating conditions (temperature, pressure, and corrosive environment), the size and configuration of the piping system, and the applicable industry standards.

Maintenance:

Aluminium pipe fittings require minimal maintenance, but regular inspection for signs of corrosion, leaks, or damage is recommended. If any issues are identified, proper repairs or replacements should be carried out promptly to ensure the continued performance of the piping system.

In conclusion, aluminium pipe fittings are excellent for lightweight, corrosion-resistant, and durable piping systems. They offer several advantages, including their lightweight nature, corrosion resistance, durability, and low maintenance requirements. Proper selection, installation, and maintenance are crucial for ensuring the performance and reliability of aluminium pipe fittings in various industrial applications.