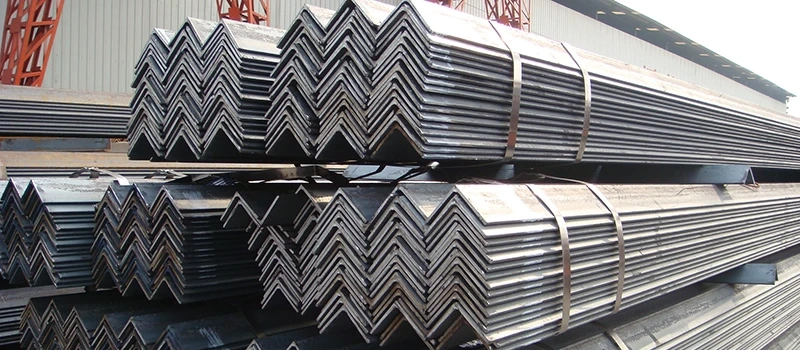

In the realm of construction, manufacturing, and structural engineering, materials that offer strength, versatility, and simplicity of fabrication are highly valued. Mild Steel (MS) angles, also known as angle irons or L-shaped structural steel, are omnipresent parts that fulfill these requirements in different applications. In this exhaustive outline, we delve into the characteristics, manufacturing cycle, applications, and advantages of MS angles, shedding light on their multifaceted role in different industries.

Understanding MS Angles

MS angles are structural steel parts described by their L-shaped cross-segment, featuring two legs of equal or unequal lengths joined at a right angle. These angles are typically produced using mild steel, a low-carbon steel variation known for its simplicity of fabrication, weldability, and cost-effectiveness. MS angles are available in different sizes, thicknesses, and lengths to suit different structural and engineering requirements.

Manufacturing Cycle

The manufacturing system of MS angles involves several means, including:

Steel Billet Creation: The cycle begins with the development of steel billets through essential steelmaking cycles like fundamental oxygen heater (BOF) or electric bend heater (EAF). These billets act as natural substances for the creation of MS angles.

Rolling Mill: The steel billets are warmed and gone through a progression of rolling mills to form the ideal cross-sectional shape. For the situation of MS angles, the billets are rolled into L-shaped profiles with two legs joined at a right angle.

Cutting and Finishing: After the rolling system, the MS angles are sliced to the necessary lengths and exposed to finishing cycles, for example, straightening, surface treatment, and inspection to guarantee dimensional exactness and surface quality.

Key Characteristics of MS Angles

Strength and Durability: MS angles offer high strength and durability, making them suitable for load-bearing applications in construction, manufacturing, and structural engineering projects.

Versatility: MS angles are versatile structural parts utilized in a great many applications, including building frames, supports, bracing, and reinforcements.

Simplicity of Fabrication: MS angles are not difficult to create, cut, weld, and manipulate using normal fabrication strategies like cutting, drilling, welding, and bending, allowing for simple customization and assembly in different tasks.

Cost-Effectiveness: MS angles are cost-viable structural steel parts contrasted with different materials, making them a favored decision for construction and it are central to engineer projects where cost contemplates.

Applications of MS Angles

Construction and Building Designs: MS angles find broad use in the construction industry for building frames, roof trusses, supports, columns, and bracing elements. They give structural stability and support in residential, commercial, and industrial buildings.

Manufacturing and Fabrication: MS angles are utilized in manufacturing and fabrication processes for producing machinery frames, hardware supports, conveyor systems, and storage racks. They act as structural parts in different industrial applications where strength and stability are required.

Infrastructure and Engineering Undertakings: MS angles play a vital role in infrastructure tasks like scaffolds, flyovers, dams, and transmission towers. They offer structural help and reinforcement in civil engineering projects requiring load-bearing designs.

Architectural and Interior Design: MS angles are also utilized in architectural and interior design applications for creating decorative elements, parts, shelving systems, and furniture frames. Their versatility and tasteful appeal make them suitable for both structural and decorative purposes.

Advantages of MS Angles

Strength and Durability: MS angles offer high strength and durability, providing reliable structural support and stability in different applications.

Versatility: MS angles are versatile parts utilized in a great many applications across industries, from construction and manufacturing to architectural and interior design.

Simplicity of Fabrication: MS angles are not difficult to create, cut, weld, and manipulate using normal fabrication strategies, allowing for simple customization and assembly in assorted projects.

Cost-Effectiveness: MS angles are cost-viable structural steel parts contrasted with different materials, making them an economical decision for construction and engineering projects.

Conclusion

MS angles, with their solidarity, versatility, simplicity of fabrication, and cost-effectiveness, are indispensable parts in construction, manufacturing, and structural engineering projects. From building frames and supports to machinery frames and architectural elements, MS angles play a vital role in providing structural stability, support, and reinforcement in different applications. As industries continue to prioritize productivity, durability, and cost-effectiveness, the demand for MS angles is supposed to areas of strength for remain, innovation and headways in structural steel fabrication for years to come.