Honing stones can be isolated into two classifications. Normal honing stones and manufactured honing stones. Regular honing stones are only that, Chefs choice knife sharpener normal stones. These stones were taken from a quarry. Manufactured honing stones can be involved various materials. The manufactured materials utilized frequently for honing stones are ceramics and jewel. Obviously every material has its advantages and disadvantages.

Regular honing stones

Normal honing stones are explicit stones that were straightforwardly taken from a mountain, cut up into straight pieces and wrapped for shipment. Instances of normal honing stones are the Ardennes coticule honing stones, Skerper Arkansas stones and Belgian Blue stones.

Upsides and downsides of normal honing stones

The primary benefit of normal honing stones is that overall they last more than manufactured honing stones. Moreover, regular honing stones gradually eliminate material. These whetstone hone gradually which implies that the final product is somewhat more refined and controllable. What\'s more, you hone your knife on a totally normal item. That could likewise be a significant benefit to many. The greatest detriment is that honing takes somewhat more than when you utilize manufactured honing stones. Also, no normal honing stone is something very similar. The grain size and the coarseness of the stone can\'t be precisely resolved per stone. That is the reason a gauge is given of, for instance, 6000 to 8000 coarseness. Particularly with regards to the higher grain measures this isn\'t something you like.

Ceramic honing stones

Ceramic honing Sharpening stone holder will be stones where engineered fired particles are consolidated and transformed into one stone. Get yourself a honing stone for a dollar in Chinatown. On the off chance that your city doesn\'t have a Chinatown, get one or move some place cultivated.

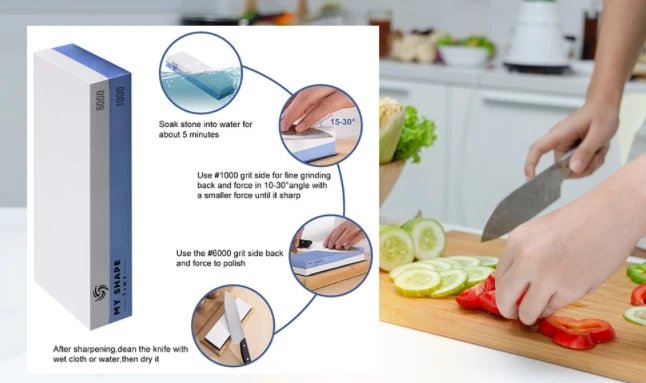

This is a "water stone" which implies you put water on it while utilizing it to coast the honing dust off it. Some lean toward an "oil stone" which implies you put oil on it. A few stones are conceived sleek. When the oil is in there water doesn\'t function admirably any longer.

This specific stone has had some utilization so it\'s doled out in the center. That makes it difficult to hold the knife at the right point. So we\'ll have to smooth it.

As a matter of fact it doesn\'t actually matter for blades, yet when you begin honing plane cutting edges you\'ll make a religion of leveling your stone.

Instructions to hone kitchen blades

Dealing with your kitchen blades is considerably more significant than purchasing extravagant ones. Truth be told, on the off chance that you make taking incredible consideration of your blades some portion of your daily schedule, a reasonable knife will last you numerous years and numerous suppers.

In case you\'re a home cook who is anxious about how to hone your blades, don\'t be—there are honing apparatuses that require almost no method (like electric sharpeners). In the event that you would like to become familiar with a more exact strategy, attempt the whetstone technique beneath. Also, in case you\'re not prepared for it is possible that, you can generally keep a sharpening steel close by and take your blades to the aces when they need honing.

Chapter by chapter guide

Step by step instructions to know when your knife Sharpening stone holder needs honing

Honing versus sharpening

Methods for honing

Tips for keeping your blades sharp

Instructions to know when your knife needs honingA sharp knife is a protected knife! A sharp knife will cut neatly and effectively, while a dull knife will require more power, in this manner setting out more open doors to slip. You\'ll have the option to tell when your knife has lost its well honed edge when it\'s not, at this point neatly cutting, or on the off chance that you feel yourself pushing down on the knife to get it to manage its work.

On the off chance that you actually aren\'t sure, attempt the paper test: hold up a solitary sheet of printer paper (or a collapsed piece of paper) and cut down through the top and out aside. A sharp cutting edge will slice through the paper; a dull edge that requirements honing will haul through the paper, or leave behind a raggedy edge.