Efficient production is the backbone of any successful manufacturing operation. Companies continually seek ways to optimize output, reduce costs, and maintain consistent product quality. Engaging manufacturing consultancy services can support enterprises by identifying inefficiencies, implementing solutions, and ensuring long-term improvements.

Here, we explore how these services help streamline processes and boost productivity.

What Do Manufacturing Consultancy Services Offer?

Manufacturing consultants analyze processes and find opportunities for efficiency improvements. Their expertise spans various areas, such as operational flow, resource management, supply chains, and compliance with standards.

Key areas where consultants provide value include:

- Improving production layouts and workflows.

- Streamlining inventory management strategies.

- Reducing unnecessary delays and bottlenecks.

- Integrating advanced tools like automation and analytics.

They systematically identify wasteful practices, introduce cost-saving measures, and align production with strategic business goals.

The Role of Manufacturing Quality Systems

A major aspect of process enhancement is the use of manufacturing quality systems. These systems define structured processes to ensure consistent adherence to quality standards throughout production cycles.

Key benefits of using manufacturing quality systems include:

- Preventing defects through robust quality controls.

- Reducing rework and material waste.

- Enhancing customer satisfaction with reliable products.

- Complying with regulatory and industry standards.

For instance, implementing standards such as ISO 9001 focuses on continuous improvement across all operational areas. An expert consultant can help businesses adopt and optimize these systems.

How Consultants Improve Production Efficiency

Below are specific ways consultants drive productivity improvements.

Analyzing Operational Processes

Consultants start by examining every aspect of the production process. This includes assessing workflows, worker productivity, machinery usage, and stock availability. By pinpointing inefficiencies, they recommend actionable improvements.

For example, if excessive time is wasted on transporting raw materials within the plant, restructuring production zones or adjusting storage policies may solve the issue.

1.Integrating Technology

Technology plays a critical role in modern manufacturing. Tools like IoT sensors, automated equipment, and predictive analytics enhance efficiency. Consultants facilitate integration by training teams and ensuring smooth operations during technology upgrades.

Pro Tip: Use data analytics to track machine downtime and schedule proactive maintenance, reducing unexpected breakdowns.

2. Optimizing Supply Chain Management

A well-organized supply chain ensures timely receipt of materials and delivery of finished goods. Consultants improve supplier selection, logistics planning, and demand forecasting, creating a seamless flow of resources.

3. Applying Lean and Six Sigma

Lean manufacturing eliminates waste, while Six Sigma emphasizes quality improvement. Consultants implement principles like Just-In-Time (JIT) inventory or DMAIC (Define, Measure, Analyze, Improve, Control) methodology to boost efficiency.

4. Training and Workforce Development

An efficient workforce is integral to productivity. Consultants provide training to improve employee skills and align them with the latest technologies and production standards.

5. Enhancing Quality Assurance

Integrating strict quality assurance protocols ensures manufacturers consistently produce high-quality goods. Manufacturing quality systems ensure tests, checks, and compliance measures are in place to maintain standards.

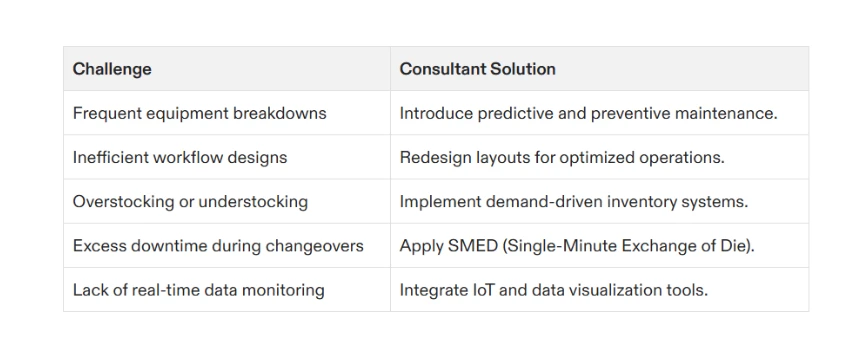

Common Efficiency Challenges

Here are some common production challenges manufacturing consultants address:

Real-World Impact of Consulting Services

Consider a mid-size electronics manufacturer struggling with high defect rates and missed deadlines. A consultancy team:

- Conducted workflow audits to identify bottlenecks.

- It recommended using ISO-certified manufacturing quality systems.

- Trained production teams on advanced machinery handling.

As a result, the manufacturer reduced reject rates by 15% and improved output consistency, meeting customer demands without delays.

Investing Smartly

While engaging consultants incurs costs, the financial and operational returns outweigh the investment. Improved processes mean better product quality, reduced waste, and higher customer retention. These gains contribute to long-term growth.

Pro Tip: Set clear business objectives before hiring consultants. This helps in measuring their impact effectively.

The World Economic Forum emphasizes adopting advanced technologies to enhance production efficiency. Incorporating practices outlined in resources like ISO standards ensures global compliance and improvement.

Final Thoughts

Manufacturing consultancy services combine technical expertise with practical insights to boost efficiency. They drive value by addressing key pain points, implementing manufacturing quality systems, and promoting proactive changes across operations. Whether reshaping workflows, integrating technology, or refining quality controls, their contributions help manufacturers stay competitive and resilient in a demanding market.

By leveraging the right expertise, companies can optimize performance, reduce costs, and achieve consistent production excellence.