The Internet of Things (IoT) is transforming how we use technology, impacting everything from smart homes to industrial automation. Printed circuit board manufacturers face new challenges and opportunities in this evolving landscape.

IoT devices require small, efficient, and reliable PCBs, often demanding miniaturized components and high-density interconnects (HDI). To meet these needs, manufacturers are turning to advanced materials and technologies. Flexible and rigid-flex PCBs are increasingly popular, offering the necessary flexibility and stability for compact, complex IoT devices.

Automation and artificial intelligence (AI) are crucial in modern PCB manufacturing. Automated processes ensure precision and reduce errors, while AI algorithms optimize PCB layouts and predict potential issues, enhancing quality and reliability.

Rapid prototyping services allow for quick iterations and faster time-to-market, which is essential in IoT development. Advanced testing facilities simulate various environments to ensure the durability and reliability of IoT devices.

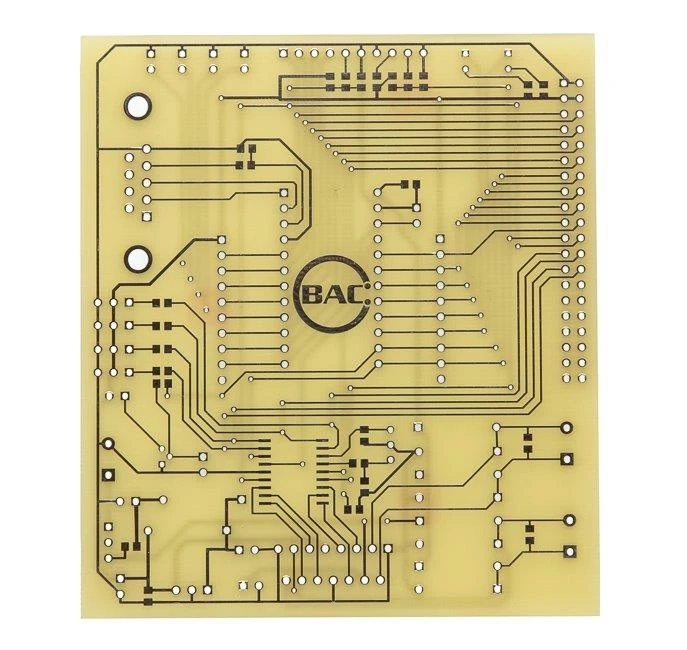

Bay Area Circuits (BAC) is leading the way in adapting to the age of IoT. As a full turnkey PCB manufacturer, BAC provides comprehensive solutions and PCB design services to support the success of IoT projects. Contact BAC to bring your IoT ideas to life.

For more information, Read this blog