An ultrasonic piezo transducer is a vital component in various industries, from medical imaging to industrial automation and non-destructive testing. These transducers use the piezoelectric effect to generate and detect ultrasonic waves, making them essential for precision sensing, distance measurement, and high-frequency applications.

However, selecting the right ultrasonic piezo transducer can be challenging due to the variety of factors involved, such as frequency, material, sensitivity, and application requirements. In this blog, we will guide you through the key considerations when choosing an ultrasonic piezo transducer, ensuring you select the most suitable one for your specific needs.

Understanding the Working Principle of an Ultrasonic Piezo Transducer

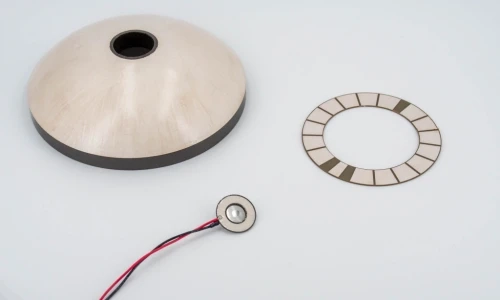

Before diving into selection criteria, it’s crucial to understand how an ultrasonic piezo transducer works. The transducer consists of a piezoelectric material—typically ceramic or quartz—which converts electrical energy into mechanical vibrations (ultrasonic waves) and vice versa.

These waves travel through a medium and interact with surfaces, allowing the transducer to measure distances, detect flaws, or create images in applications like medical ultrasound and industrial inspections.

Factors to Consider When Choosing an Ultrasonic Piezo Transducer

1. Application Requirements

The first and most important step is identifying the intended use of the transducer. Some common applications include:

- Medical Imaging (e.g., ultrasound machines)

- Non-Destructive Testing (NDT) (e.g., flaw detection in materials)

- Industrial Automation (e.g., object detection, liquid level measurement)

- Sonar and Underwater Sensing (e.g., marine navigation and fish detection)

- Cleaning and Processing (e.g., ultrasonic cleaning systems)

Each of these applications requires different specifications, so it’s essential to define your purpose clearly.

2. Frequency Range

Ultrasonic piezo transducers operate at different frequencies, usually between 20 kHz to several MHz. The right frequency depends on your application:

- Low Frequencies (20 kHz – 200 kHz): Suitable for high-power applications like ultrasonic cleaning and welding.

- Mid Frequencies (200 kHz – 1 MHz): Commonly used in industrial applications like fluid level measurement and object detection.

- High Frequencies (1 MHz – 15 MHz): Best for medical imaging and high-precision inspections, as they provide finer resolution.

3. Sensitivity and Power Output

- Higher sensitivity means better signal detection, which is essential for medical diagnostics and flaw detection.

- Power output is crucial for applications like ultrasonic cleaning, where strong vibrations are needed.

Choosing a transducer with the right balance of sensitivity and power ensures accurate results.

4. Material and Durability

The material of the piezoelectric element plays a key role in performance. The two most commonly used materials are:

- PZT (Lead Zirconate Titanate): Offers high sensitivity and efficiency, making it ideal for industrial and medical applications.

- Quartz: Provides stability and durability, often used in high-frequency applications.

For harsh environments (e.g., underwater sonar or high-temperature applications), encapsulation and coatings should also be considered for longevity and protection.

5. Beam Angle and Directivity

- Narrow beam transducers focus waves in a specific direction and are ideal for distance measurement and imaging applications.

- Wide beam transducers provide broader coverage, which is beneficial for area-based scanning and detection systems.

Understanding the beam angle and directivity helps optimize performance for your specific application.

6. Mounting and Integration

Consider how the transducer will be integrated into your system. Some key aspects include:

- Surface-mounted vs. Immersed transducers (depending on the application)

- Electrical connectivity options (e.g., wired or wireless)

- Size and shape constraints based on device design

7. Environmental Factors

If the transducer is used in extreme conditions, consider:

- Temperature resistance (some piezo materials degrade at high temperatures)

- Moisture and waterproofing (important for underwater applications)

- Chemical resistance (needed in medical or industrial settings)

Choosing the right transducer based on environmental factors ensures longevity and reliability.

8. Cost and Availability

Balancing cost and performance is essential, especially in high-volume applications. Custom-made transducers may offer better performance but come at a higher cost. Off-the-shelf options are more affordable but may not meet specific requirements.

Common Mistakes to Avoid When Choosing an Ultrasonic Piezo Transducer

- Ignoring Frequency Requirements: Choosing the wrong frequency can lead to poor resolution or inadequate penetration depth.

- Overlooking Sensitivity Needs: Low-sensitivity transducers may not detect weak signals, affecting measurement accuracy.

- Selecting the Wrong Beam Angle: A misaligned beam can lead to inaccurate results or missed detections.

- Not Considering Environmental Factors: Using a transducer in unsuitable conditions can lead to premature failure.

- Focusing Only on Cost: Cheaper transducers may not provide the desired precision or durability.

Future Trends in Ultrasonic Piezo Transducers

As technology advances, ultrasonic piezo transducers are evolving with:

- Miniaturization for portable and wearable medical devices

- Integration with IoT for real-time monitoring and smart automation

- Improved materials for higher sensitivity and durability

- Advanced signal processing algorithms for better accuracy

The demand for high-precision sensing and non-contact measurement is growing, making ultrasonic piezo transducers even more critical in modern industries.

Conclusion

Choosing the right ultrasonic piezo transducer involves understanding your application, selecting the correct frequency, evaluating sensitivity, and considering environmental factors. Whether it's for medical imaging, industrial automation, or ultrasonic cleaning, the right transducer can significantly improve performance and reliability.

By following the selection criteria outlined in this guide, you can ensure that your ultrasonic piezo transducer meets the exact needs of your application, leading to better efficiency, accuracy, and long-term durability.