Bulk material handling forms an integral part of any commercial process. Industries like manufacturing and mining rely on conveyor systems for material handling. Picking the right conveyor system can be difficult with many suppliers to choose from.

You can choose a suitable material handling conveyor system based on the material you're transporting. Other factors to consider when looking for a well-designed conveyor system include material type, flow rate, speed, and mechanism.

Conveyor Systems for Bulk Material Handling

Transporting tons of bulk material remains a challenge for most industries. You need a streamlined process that ensures safety, compliance, and performance. When the material isn’t flowing properly, even the most advanced systems fall short on performance. Common problems that industries face during bulk material handling are:

Poor Flow Rate – Sometimes, bulk materials form a stable arch that blocks the flow completely. Lifting such problematic materials requires professional help and heavy-duty equipment. Stock Contamination – When bulk material stagnates over time, it can contaminate a whole collection of products. Accumulated material affects material quality, colour, texture, and several other safety norms.Machine Damage – Material build-up often results in structural damage. The damage commonly manifests in the form of small cracks and dents. In such cases, businesses often hire experts to repair the damage.You have many benefits to consider in using a conveyor system. First, this bulk material handling equipment decreases the need for manual labour. It also helps reduce labour costs in the facility. Second, a custom-made conveyor system offers greater control over your inventory. It ensures there are no misplaced items or damaged goods. Lastly, a material handling conveyor system ensures workplace safety with its ergonomic design and helps meet production goals.

To design a material handling conveyor, you have to consider several factors. Depending on your processing facility and type of material, you can get a customized design. Other ways to reduce downtime with a well-designed belt conveyor include setting the conveyor belt to pull rather than push to maximize the load capacity. You can also consider the flow rate to choose between a moderate and fast-paced belt. Moreover, you can review options with a conveyor belt designer as per your business needs.

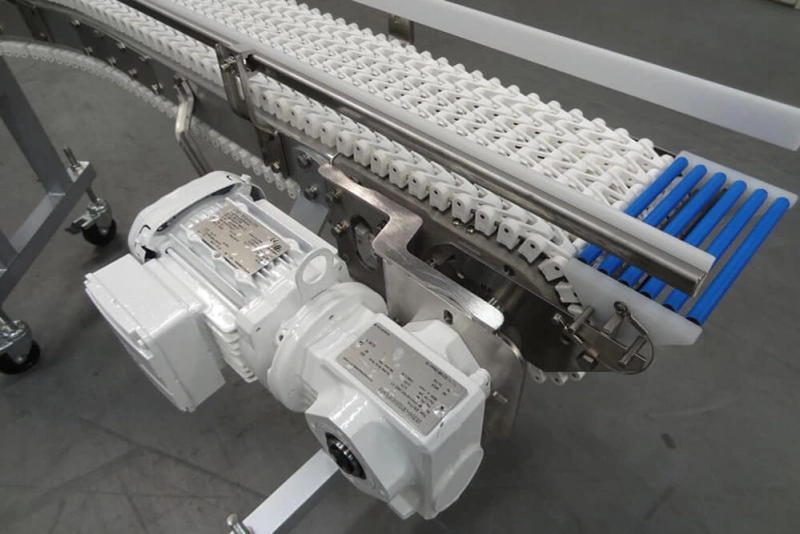

Different Types of Conveyor Systems

Conveyor systems are common in industrial and commercial processes. They transport products from a manufacturing unit or a packaging line. The material handling system starts from a single point of delivery to a point of pick-up. Conveyor systems have a design that can consist of leather, rubber, plastic, metal, or fabric.

Conveyor systems also have a particular thickness and tensile strength. Top industries use heavy and lightweight belting in their design. When you're looking for transfer conveyor manufacturers, get a quote from an expert.

There are some standard options you can start with.

Belt Conveyor System

Engineered to ensure continuous operation, a conveyor belt works around a pulley system. The design features one pulley that rests at the head of the conveyor. Combined with a drive unit and a heavy-duty belt, the system transmits force and moves the materials forward. Conveyor belts are most commonly used at airports, but these belt systems have a wide range of applications.

This type of conveyor system addresses changes in elevation. They're very useful in mining operations and oil refineries. They provide a cheap and secure way to transport products over a long-distance haul. Their design also features sidewalls to prevent any spillage.

Screw Conveyor System

This type of conveyor system transports bulk quantities of granular solids (powder and grains). These systems have higher operational efficiency. Designed with a rotating screw shaft, they can transport goods of varying densities. This material handling infrastructure comes with a flexible design.

Common products transported by screw conveyors are fertilizers and pesticides, animal feeds, pulp and grain, wood chips, cement, ash, and solid wastes. You can construct the conveyor system in a variety of positions. Based on your industrial needs, you can transport bulk materials that are abrasive in nature or are hazardous or toxic. These conveyor systems also come in handy for transporting free-flowing fluids and hygroscopic materials.

Chain Conveyor System

Chain conveyor systems transport materials that are wide, lengthy, or heavy. The design promotes the continuous transport of several products at a time.

Many industries rely on chain conveyor systems because these systems allow the uniform movement of materials. Businesses use this material handling technology for their production lines. For instance, the automotive industry mostly depends on chain conveyors.

There is a wide range of options available for these systems. For instance, a pallet handling conveyor uses a motor to move two to four chains at a time. The best thing about this system is that it's inexpensive.

Meanwhile, a factory handling conveyor uses medium-sized conveyors in food manufacturing units. The system also features several kinds of conveyor systems sharing the same perimeter.

Get a Custom Conveyor System Design

A conveyor system tailored to your facility can reduce your maintenance costs. Before settling on a design, talk to a professional engineer for guidance. Get in touch with experts who understand accumulation conveyor design. You can also specify the quantity and type of material that requires transportation. Accordingly, you can check for safety and health certifications and other licenses when hiring a professional.

Material handling conveyor experts have the experience and training necessary to achieve project goals. The best transfer conveyor manufacturers work with an expert team. This can include mechanical engineers, designers, and site supervisors.

We ensure the installation and maintenance of conveyors for your manufacturing unit. Talk to our engineers and determine which conveyor type is best for your business needs.

Call our experts for more information!