Your consumers will be able to rely on the same exceptional quality each time they open a box of your pre-rolls if you install some automation and equipment in your plant, such as cone filling machines and other pre-roll machines. There is a pre-roll machine that fits your demands and budget, regardless of whether you are just getting started or wish to branch out into other areas of this quickly expanding market.

Making a lot of pre-rolled cones by hand is just not cost-effective. Fortunately, it is not necessary for the current cannabis market. From the blossom to the finished pre-roll, there are numerous machine alternatives available today that can improve the final product that customers can rely on and expedite the entire process. Since the grind is what turns your flower from buds into particles small enough to fit into pre-rolled cones, we like to say that it begins with the grind. Nevertheless, there are numerous grinders that produce those particles in various ways, and we shall discuss their unique advantages and disadvantages that impact the end product.

Sifting, which is sometimes disregarded yet is essential to creating high-quality pre roll filling machine, is the next process that a pre-roll machine may assist with. By eliminating stems, seeds, and other debris that can shred your pre-rolled cones or produce hot spots that could cause canoeing or accelerate the rate at which one side of your pre-roll burns down, sievers help guarantee uniform particle size. Any pre-roll production process must have the appropriate sifter and the necessary size screens.

Why choose us

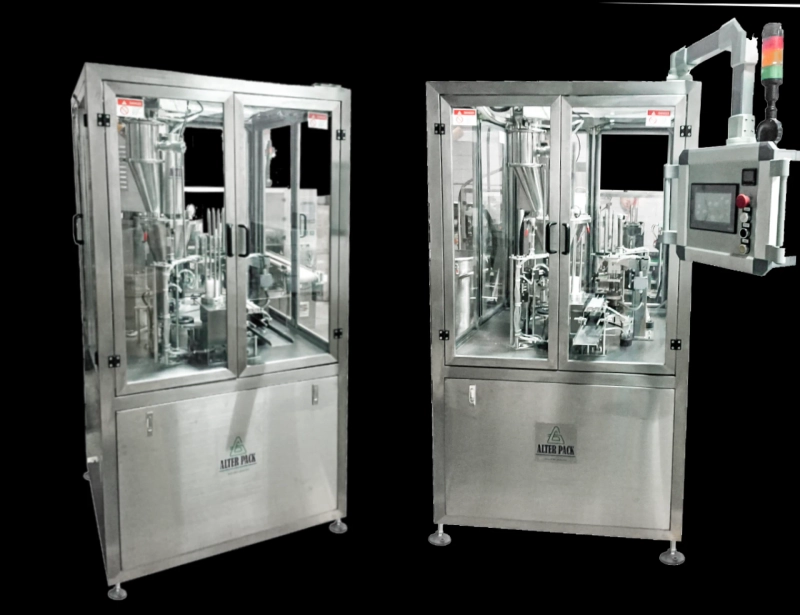

The cone filling equipment itself should not be disregarded and although there are many various models, sizes, and price points to choose, these devices are the most important and prevalent pre-roll machines in the cannabis market. Their purpose is to manually pack and fill pre-rolled cones. Pre-roll machines are now available for every level of production, ranging from tabletop bumpboxes to sophisticated, automated pre-roll injection machines. You must weigh the unique advantages, disadvantages, and intricacies of each option to choose the best one for you and your company.