Catering is the art of offering food and beverage facilities to customers in areas where people work together or where people, such as the elderly, patients and children are sheltered. With industrialization, the trend towards out-of-home nutrition has accelerated in recent years. These results indicate the importance of food safety in catering and food businesses. From this viewpoint, while food safety should be the most critical concern in the food service industry, adequate focus and attention is not paid.

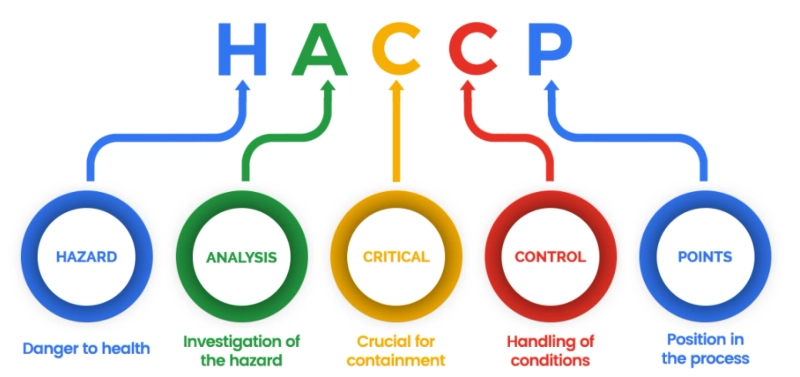

Hazard Analysis Critical Control Points is a comprehensive approach to the diagnosis, measurement, and control of hazards to ensure food safety from production to consumption.

How to set up a HACCP system in food business? The steps:

Definition of Terms and Intent: It should be determined the hazards (microbiological, physical or chemical) are discussed in the HACCP framework, whether the work relates to the protection of the product and/or the microbial quality elements, whether the safety of the product will be assured at the end of processing or at the point of consumption, as well as the conditions of storage and use.

Creation of the HACCP team: The HACCP team should be consisting of a specialist in quality assurance, a specialist in the manufacturing line, an engineer who knows the hygienic layout, the efficiency and the use of equipment and materials, and an expert in hygiene and sanitation.

Identification of the product: full descriptions of the products should be drawn up, within this scope, the composition, the layout of the product, the processes applicable to the product and the guidance in the services should be defined.

Creation of the Production Flow Chart: Before conducting the hazard analysis, production flow charts relating to meals should be drawn up. For this reason, applications beginning with the collection of raw materials for manufacturing and operation should be clearly explained in the flow chart along with the technical details. Then it has to be assessed.

Hazard Analysis: In order to achieve this, starting from the raw material, all the phases that the commodity encounters before it reaches the customer should be planned in the form of a flow chart. The general flow chart relating to the goods should provide information on shipping, receipt of the raw material, storage in the company, processing phases, heat treatment time and temperature, pH specifics, water activity, etc. variables influencing the survival possibility of microbes and the growth of the bacterial during shipment, storage, and shelf life. Infrastructure details, construction, machinery capability used during development, storage areas and environments, cleaning and sanitation procedures should be added to these schemes.

Decision Tree and Determination of Critical Control Points: In order to assess the potential risks by doing a hazard review at the first stage, it should be decided if each hazard at each stage is a CCP or not by using a decision tree. Using the decision tree, the phase or stage identified as CCP should be checked and the CCP should be minimized to an absolutely preventable or acceptable level with measures.

Limitation and Control Criteria: Criteria for the monitoring of critical control points should usually be implemented as critical limits by defining tolerance limits.

If you need HACCP certification consultancy or ask questions about how to apply HACCP in food industry or any other sector, you can contact us, and we can help you with the process and application for HACCP certification.