As the world began to take clean air and quiet cities seriously, old-school diesel towable boom lifts suddenly felt like relics of the past. But let’s talk about a hybrid towable lift—the best of both worlds. Think of it as your trusty ute (utility vehicle) that can suddenly switch to electric mode when you’re indoors or need to lower your noise. You get the power for outdoor work and whisper-quiet performance inside a warehouse. (Tesla mode, anyone?).

In this post, we’ll cover:

- Emissions vs regulations: Why diesel alone doesn’t cut it anymore—and how hybrids reduce pollutants without losing muscle.

- Fuel and running costs: We’ll break down what’s cheaper over time—diesel, electricity, or both.

- Noise levels: How a hybrid lift lets you nap—or let someone else nap—while it runs.

- Where each shines: When a diesel lift still rules the rough terrain and when a hybrid showboats indoors.

- Care & maintenance needs: Juggling engine service with battery checkups—it’s a dual system.

- Full picture on sustainability: Understanding the carbon savings and the battery footprint.

By the end, you’ll see why hybrid towable boom lifts aren’t just a trendy gadget—they’re a smart choice in our tighter-emission era after 2025. Let’s figure out which model works best for your job and your planet.

As environmental regulations are tightening worldwide, you have to choose the right towable boom lift.

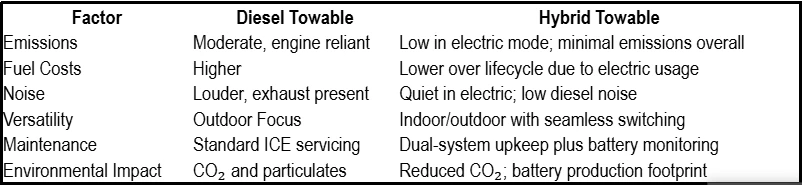

Here's a breakdown of hybrid and diesel options across key parameters:

Comparing Hybrid Vs. Diesel Towable Boom Lifts

1. Power Source & Emissions

Diesel Lifts: Utilise internal combustion engines, which emit CO₂ and particulates. The newer diesel machines are built with Tier 4 emissions controls and lighter steel frames. They produce less CO₂ per hour than the older models.

Hybrid Lifts: Pair lithium batteries with a smaller diesel unit. They can work on indoor or lightweight tasks in electric-only mode, cutting emissions, with diesel generators used for heavy-duty or recharge functions.

2. Fuel Efficiency & Operational Cost

- Diesel Lifts: Even with better fuel efficiency relative to petrol lifts, diesel remains a major operational expense. Torque at low RPM is beneficial for efficiency, but the costs add up over extended periods.

- Hybrid Lifts: Enable significant savings —batteries handle lighter duties, and the diesel engine runs less. Some of the regenerative systems actively charge batteries while running. Some hybrid models, for instance, shut down after 90 seconds, saving fuel and noise.

3. Performance & Versatility

- Diesel Lifts: Offer enhanced outdoor performance and increased lift capacities. Best suited for rough terrain and areas with sustained power.

- Hybrid Lifts: Tend to match diesel performance. Some models are fully recharged in under 1 hour, utilising fast-charging technology to replenish both USB devices and the built-in battery pack quickly. They are compact and feature an electric mode for use indoors and in mixed job sites.

4. Noise & Workplace Impact

- Diesel Lifts: Produce loud, modulating sound and exhaust, typically unsuitable for urban or indoor settings.

- Hybrid Lifts: Silent during electric operation to contribute to reducing the noise levels in the work environment. When the small diesel generator fires up, the noise is still considerably less than full diesel power.

5. Maintenance & Lifecycle

- Diesel Lifts: They require regular servicing, including oil changes, filter replacements, and maintenance of the emissions system. Heavy steel can mean a greater maintenance burden.

- Hybrid Lifts: Dual systems are more complicated, but the latest-model devices have simplified diagnostics. Remote access for error detection enhances the device's availability. Battery pack management is a new consideration, although it results in less engine wear.

6. Total Environmental Impact

Life cycle analyses show clear benefits from partial hybridization: 25–75% electrification can dramatically cut CO₂, ozone-depleting substances, and acidification during use. However, battery manufacturing adds environmental costs in the form of the materials used and the energy required to extract, process, and manufacture them. Even though the energy savings from battery use outweigh these impacts.

Final Outlook

Hybrid towable boom lifts are emerging as the practical middle ground. They offer strong outdoor capabilities with notable reductions in emissions and noise. While they cost more upfront and involve dual-system maintenance, they have lifecycle benefits like cleaner operations, fuel and noise savings, and regulatory compliance. These benefits make them ideal for mixed urban and interior job sites in the post-2025 era.

Bottom Line

Towable hybrid boom lifts are proving to be the ideal solution, offering exceptional outdoor performance while significantly reducing emissions and noise. They’re more expensive initially and require maintaining two systems. Still, all the advantages in their lifecycle (cleaner operations, fuel and noise savings, regulatory compliance) make them perfect for mixed urban and interior job sites in the post-2025 era.

Frequently Asked Questions (FAQs)

1. Why is my towable boom lift moving jerkily or slowly?

Sluggish and jerky flow is typically related to a hydraulic problem. It can be caused due to dirty fluid, worn seals, or hoses. Contamination of hydraulic oil limits the flow, which results in slow or non-uniform operation of the boom. Additionally, exhaust filters and flush fluids should be replaced according to the manufacturer's schedule. Check the tyres and seals as well, and repair them where necessary.

2. What causes boom lifts to not start or stall shortly after starting?

Typical offenders include empty or contaminated fuel, a clogged gasoline filter, a dead battery, or a faulty security system (tilt or seat mattress). When it won't start or stalls, inspect the fuel level and purity, replace filters, check the battery charge, clean the terminals, and ensure that no safety switches prevent operation.

3. How do I fix platform instability or tilt warnings while in use?

The main cause of instability can be uneven ground, overloading, or improperly calibrated tilt sensors. Whenever possible, it is necessary to place the lift on the rock-solid ground and ensure that the weight limits of the platform (as well as tools and material) are adhered to. If tilt alarms persist while conditions are steady should be regarded as an indication of improper functioning. Let a technician check and recalibrate the tilt sensor.

4. What should I check when electrical controls become unresponsive?

Unreliable controls or controls that seem to behave erratically are often indicators of a fault in the electrical system. It is typically caused by a loose connector, broken wires, a faulty switch or sensor, or a weak battery. Fully inspect and visually check all cables and harnesses, tightening or replacing loose wires as needed. Test or check switches and sensors using a multimeter, and replace the battery or clean terminals as necessary.

5. Can I use a towable boom lift on grass or slopes?

Using a towable lift on grass or a sloped surface can be challenging. The unstable ground may lead to instability and when the trigger gear is activated, it can cause the plate to malfunction. Some rental supervisors require soil testing before use. The stabiliser pads should be used at all times to ensure safe operation, and the unit should be levelled to ensure stability. It is not advisable to work on a surface that is not sufficient to support the weight of the equipment. Where there is uncertainty, consult an engineer or obtain additional ground support.