In the era of electrification and ever-increasing power demands, managing heat has become one of the most critical challenges in modern electronics. As devices become more compact and power densities rise, efficient thermal management is no longer optional—it is an essential factor that determines overall performance, reliability, and even product lifespan. This is especially true for systems that use Insulated Gate Bipolar Transistors (IGBTs), which are widely used in power electronics for industrial drives, electric vehicles (EVs), renewable energy systems, and rail traction. One of the most effective tools to manage heat in these systems is the IGBT cold plate.

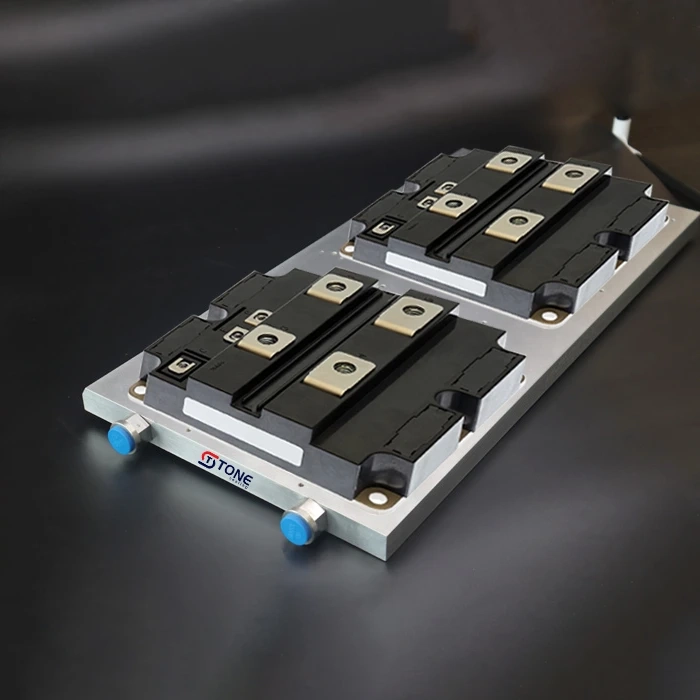

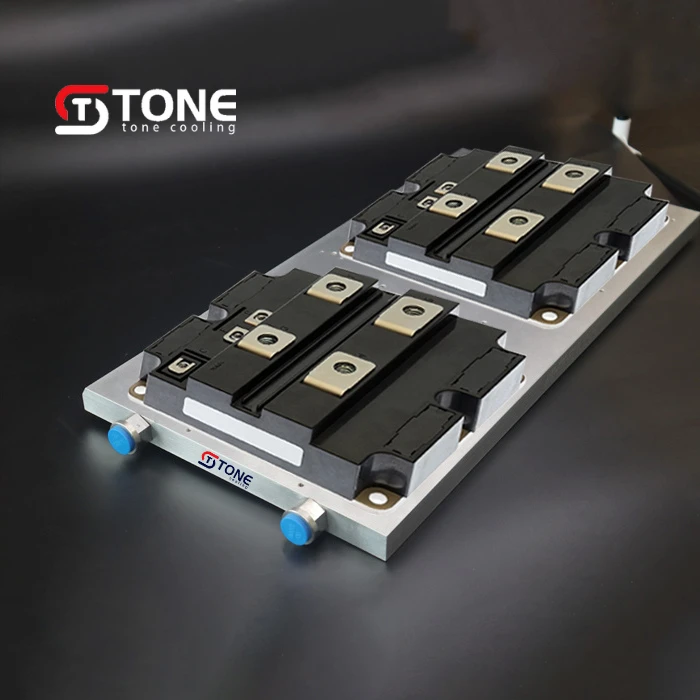

At Tone Cooling Technology Co., Ltd., we specialize in designing and manufacturing high-performance IGBT cold plate cooling solutions that address the growing thermal challenges of the power electronics industry. Our cold plates are custom-engineered to deliver precise, reliable, and powerful heat dissipation for IGBT modules across various applications.

What Is an IGBT Cold Plate?

An IGBT cold plate is a liquid-cooled heat sink designed specifically to remove heat from IGBT modules. Integrated into systems where air cooling is insufficient, these aluminum or copper baseplates allow fluid to pass through internal channels, effectively absorbing and transporting heat away from the high-power semiconductor devices.

These cold plates maintain temperature uniformity, prevent overheating, and enhance the performance of IGBT modules by mitigating the risk of thermal stress or failure.

Why Thermal Management in IGBT Modules Is Critical

1. High Power Density

IGBTs are common in high-voltage and high-current applications such as:

- Motor drives

- Inverters

- Power supplies

- Energy storage systems

With higher power density comes increased heat generation. Without proper cooling, the temperature of an IGBT module can exceed safe operational limits, risking thermal runaway or catastrophic failure.

2. Thermal Stress and Degradation

Over time, repeated thermal cycling—heating up during operation and cooling down when idle—can cause internal stress that degrades the bond wires, solder joints, and thermal interfaces inside the IGBT module.

3. Efficiency and Performance

Even small increases in IGBT junction temperature can reduce efficiency, lead to power losses, and significantly shorten the operational life span of the system.

Therefore, integrating a robust, well-engineered IGBT cold plate is critical to ensuring long-term reliability and optimal performance.

How IGBT Cold Plates Work

1. Heat Transfer Mechanism

Unlike passive cooling, IGBT cold plates use liquid coolant (typically water, water-glycol mixtures, or synthetic coolants) to transfer heat away from the IGBT. The fluid enters the plate, absorbs heat from the hot surface of the IGBT, and exits the plate, carrying the heat away to a radiator or chiller unit.

2. Internal Channel Design

Cold plates feature internal channels that can be:

- Serpentine: For uniform flow and easy manufacturability

- Pin-fin or micro-channel: For enhanced surface area and turbulence, enabling better thermal performance

3. Mounting to IGBT Modules

IGBT modules are typically bolted or clamped to the cold plate using thermal interface material (TIM) to ensure proper contact. The cold plate then acts as a thermal bridge between the module and the coolant loop.

4. Material Considerations

Materials like aluminum and copper are used due to their high thermal conductivity. Aluminum offers good performance and lower weight, while copper provides superior heat dissipation.

Tone Cooling's IGBT Cold Plate Solutions

At Tone Cooling Technology Co., Ltd., we deliver customizable, high-efficiency IGBT cold plate solutions, tailored to each customer’s specific design and thermal requirements.

Our expertise includes:

- Custom Channel Design: Micro-channels, pin fins, serpentine flow paths, and more

- Advanced Welding Technologies: Friction stir welding and vacuum brazing for robustness and zero-leakage

- Material Selection: Copper, aluminum, or hybrid materials based on your performance goals

- Simulation & Design: CFD modeling and thermal simulation for optimal flow and heat dissipation

- Compatibility: Designed to match IGBT modules from leading manufacturers (Infineon, Mitsubishi, Fuji Electric, etc.)

Key Benefits of Using IGBT Cold Plates

✅ Enhanced Cooling Efficiency

Liquid cooling is much more efficient than air cooling, often 3–10 times more effective, making cold plates ideal for high-power-density applications.

✅ Smaller System Footprint

With better cooling comes the ability to shrink form factors or pack more functionality into the same space—crucial for compact enclosures like EV powertrains or data centers.

✅ Longer Component Life

Maintaining a lower, more consistent temperature reduces thermal fatigue, increasing the service life of IGBTs and other components.

✅ Lower Maintenance

A well-designed IGBT cold plate system can operate reliably for years with minimal maintenance, especially when integrated into a closed-loop cooling system.

✅ Operational Stability

Temperature fluctuations can cause electrical parameters to drift. Cold plates minimize such changes, contributing to system precision and stability.

Also Read: Benefits of IGBT Cold Plates in Power Electronics [Infographic]

Design Considerations for IGBT Cold Plates

When designing an IGBT cold plate, it’s essential to consider:

⚙️ Thermal Requirements

Understand the heat load, maximum allowable junction temperature, and ambient operating conditions.

🧪 Coolant Selection

Choose a fluid that balances thermal capacity, compatibility, corrosion resistance, and budget. Options include:

- Deionized water

- Glycol-water mixtures

- Synthetic oil-based coolants

🛠️ Mounting Interface

Ensure a flat and smooth surface to maintain proper contact between the IGBT and cold plate.

Use thermal paste or gap fillers as recommended.

💧 Flow Rate and Pressure Drop

Balance the desired heat transfer with available pump power and flow capacity.

🔄 Maintenance and Flexibility

Consider ease of access, cleaning protocols, and modular designs if the system will scale.

Case Study: EV Inverter Cooling With Tone Cooling’s Cold Plate

Client Problem:

An EV manufacturer faced thermal throttling issues with their IGBT-based inverter system, which led to degraded acceleration and component overheating.

Our Solution:

We designed a custom IGBT cold plate with:

- Enhanced pin-fin microstructuring for better flow turbulence

- Lightweight aluminum body for vehicle optimization

- Leak-proof friction stir welded seals

Results:

- 25% improvement in cooling efficiency

- 20°C reduction in average IGBT temperature

- Extended service life and improved driving performance

Smart Integration With Other Cooling Technologies

Although highly effective on their own, IGBT cold plates can be integrated with other cooling components, like:

- Heatsinks (for added surface radiation)

- Fans (for hybrid systems)

- Thermal interface materials (TIM) customized with nanoparticle fillers

- Vapour chambers or heat pipes for additional heat spreading

This makes them an excellent addition to multi-tiered cooling systems that need to work under extreme conditions.

A high-performance IGBT cold plate represents one of the most effective strategies for extending the life and enhancing the performance of your power electronics systems. With the rise of electric mobility, renewable energy, automation, and high-power computing, the need for reliable and compact thermal management has never been greater.

FAQs About IGBT Cold Plates

❓ What is the lifespan of an IGBT cold plate?

▶️ With proper maintenance and operation within specs, Tone Cooling’s cold plates can last 10 years or more.

❓ Can I retrofit an IGBT cold plate into an existing system?

▶️ Yes, we offer custom-fit cold plates that align with existing mechanical constraints and fluid loop architecture.

❓ What coolant is best for cold plates?

▶️ For most applications, deionized water or ethylene glycol mixtures offer a good balance of thermal performance and cost. We can recommend based on your system’s needs.

❓ Are Tone Cooling's cold plates compatible with all IGBT modules?

▶️ Yes. We support all major module formats such as:

-62mm modules

-EconoDUAL™ modules

-PrimePACK™

-Customized footprints

❓ How can I ensure the cold plate performs optimally?

▶️ Use it with approved mounting torque, proper TIM, and within rated flow/pressure specs. We also provide engineering support and simulation validation for peace of mind.