Incoloy 800Ht Plates are one of the most durable and toughest alloys. It has a high tensile strength and good elongation properties. These features are ideal for applications that involve welding, bending, and other metalworking processes. This material is also resistant to carburization and nitriding atmospheres.

Exceptional tensile strength

Incoloy 800ht is a nickel-chromium alloy that provides excellent resistance to oxidation and high-temperature environments. Incoloy 800HT Plates are used in various types of processes and machinery. This alloy also demonstrates excellent resistance to chloride stress corrosion cracking.

800 series alloys are used in petrochemical furnace cracker tubes, electrical heating elements, process piping, and extruded tubing for reforming furnaces. They are also utilized in retorts and heat exchangers for nitric acid media.

The alloy 800 HT exhibits excellent resistance to chlorine, steam, industrial chemicals, and salt water. It has good elasticity, high tensile strength, and resistance to pitting corrosion. Alloy 800 is suitable for welding by common stainless steel welding techniques.

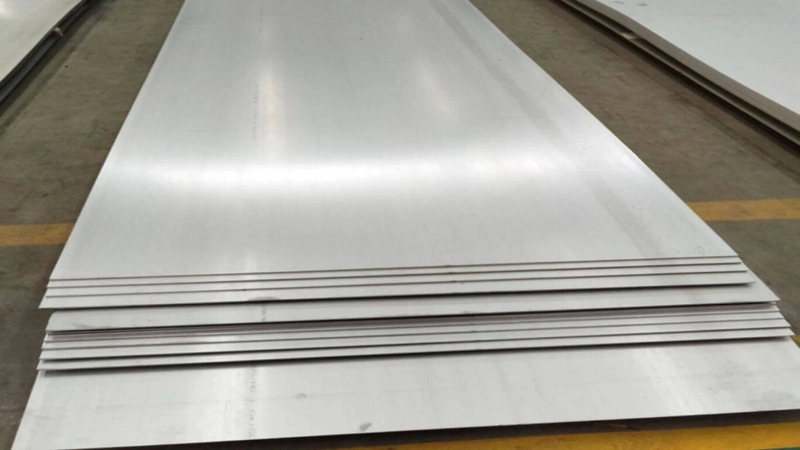

Incoloy 800ht Plate is manufactured with the help of advanced tools and techniques to ensure durability and long service life. These sheets and plates are tested according to industry standards and specifications.

Good elongation and impact resistance

Alloy 800HT is an alloy with excellent corrosion resistance and high oxidation resistance. It is an alloy of nickel, chromium, and aluminum. This alloy is used for many applications, such as boilers, heat exchangers, and retorts. In addition, it is also widely used for chemical and petrochemical processing.

Incoloy 800HT is primarily used for applications that require good elongation and impact resistance. A high chromium content helps prevent oxygen from corroding. In addition, the alloy has good resistance to chlorine, fresh water, and seawater. Another benefit of the alloy is its high flexibility. The material is particularly suited for nuclear energy systems.

Incoloy 800HT is used for heat-treating equipment such as superheater tubing, dispensing equipment, and dispensing pumps. The alloy is also used in the chemical and petrochemical industries for piping systems in nitric acid media.

Resistance to carburization

If you are looking for high-temperature resistance, then the 800 series alloys are your best option. They are known for their excellent high-temperature strength and corrosion resistance. In addition, these alloys are known to resist carburization.

The 800HT alloy is used in a variety of applications. For example, it is employed in cracking furnaces and in heat exchangers. It also has applications in the chemical and petrochemical industries. Moreover, it is used in nuclear power plants.

The 800H alloy is a chromium-nickel-aluminum alloy characterized by an excellent combination of high-temperature strength, oxidation, and corrosion resistance. Also, this alloy has a high concentration of nickel and chromium. These elements allow the alloy to withstand chloride stress-corrosion cracking.

The composition of the alloy determines the degree of carburization. Carburization is the process whereby a metal is subjected to a high-temperature environment, which causes it to absorb a large amount of carbon. During this process, a layer of alumina is formed on the surface of the metal.

Nitriding atmospheres

Nitriding atmospheres on Incoloy 800Ht plates are not harmful to the alloy. This is because the alloy has a chemical balance that provides excellent resistance to nitriding.

This alloy is also resistant to oxidation and hydrogen. It is a nickel-iron-chromium alloy that is commonly used in various applications. A high concentration of nickel allows the alloy to resist stress fracture corrosion.

These Incoloy 800Ht Plates are used in nuclear power plants, petrochemical processing, chemical processing, and heat treatment equipment. The alloy can also be used for heat exchangers in nitric acid media, superheater tubing, and piping systems.

Alloy 800HT has good elongation and flexibility and is easily welded. It can be hot-worked and cold-worked. Besides, its tensile strength is superior to standard austenitic stainless steel.

Typical applications

Incoloy 800Ht plates are used in heat exchangers and heat treatment equipment. They have high resistance to oxidizing and reducing atmospheres. Moreover, it is also resistant to carburizing conditions. Similarly, it is also used in the chemical and petrochemical processing industries. It is also widely used in power generation facilities.

The nickel-based alloy 800HT is an option for nuclear reactors operating in gas-cooled high-temperature environments. It is also used in pressure vessel service above 815degC. However, its tribological behavior needs thorough knowledge. A well-controlled crystal grain provides a high creep strength. This strength is achieved through the use of high-temperature heat treatments.

Typical applications of Incoloy 800HT plates include power generation, petrochemical, chemical, and food processing industries. The material is also used for piping systems and furnace components.