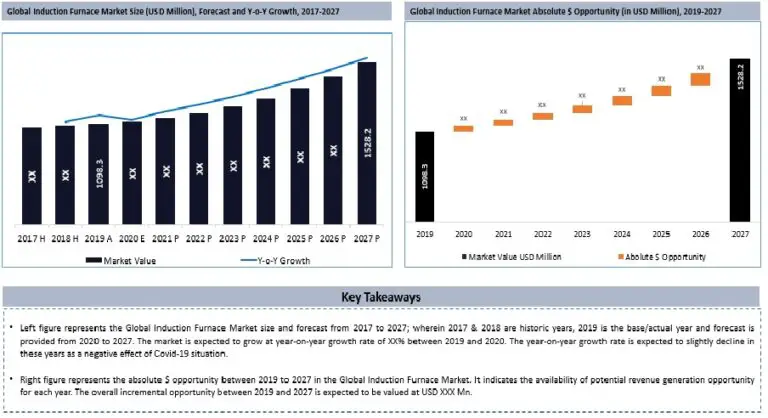

The Global Induction Furnace Market was valued at USD 1,098.3 million in 2019 and is projected to reach USD 1,528.2 million by 2027, expanding at a CAGR of 5.1% during the forecast period. In terms of volume, the market is projected to expand at a CAGR of 4.2% during the forecast period. Induction furnace is an electrical furnace that comprises shell, inductor coil, crucible, and cooling system. It enables melting of metal with the help of induction heating. It is an easily-controlled and energy-efficient melting process that is based on the heating effect of the electromagnetic field. The magnetic flux in induction furnace generates the heating effect in the internal side of the furnace. The inductor coil produces magnetic flux when alternating current passes through it.

Market Dynamics

Large-scale projects spread across sectors from petrochemicals to infrastructure and real estate have ensured a high demand for base metals such as steel and copper. The different projects include construction, infrastructure, petrochemical industries, and all large users of steel and copper. Moreover, several long-term trends are currently enhancing growth in copper demand and are expected to continue the same trend in the coming years. These trends include increased use of renewable energy sources & energy efficiency, wide uptake of electric vehicles (EVs), increased consumer use of electronics that require significant amounts of copper to function. The steel and copper industry is expected to grow in Asia Pacific due to robust demand, policy support, and increasing investments.

The macroeconomic factors such as growing industrial activities and the upgrade in metal processing & production and an increase in the demand for refined metals in many countries, thus augmenting the adoption of induction furnace. Specialized industrial induction furnaces are crucial to the processes performed by foundries, manufacturers, mining companies, engineering operations, and steel production companies. Metallurgical industrial induction furnaces are at the center of operations for these industries, providing induction heat necessary to perform processing functions.

CLick For Free Sample Report – https://growthmarketreports.com/request-sample/114

Segmental Outlook

On the basis of types, the induction furnace market has been bifurcated into coreless induction furnace and channel induction furnace. The coreless induction furnace segment held a significant market share in 2019 and is anticipated to expand at considerable CAGR during the forecast period due to increasing applications of coreless induction furnace in the steel industry and copper industry. The coreless induction furnace comprises of the coils carrying electrical current. A metallic charge consisting of pig iron, scrap, and ferroalloys are usually melted in such a vessel. When an electrical current is applied to the coil, a magnetic field forms that in turn generates thermal energy resulting in the melting of the charge.

Regional Outlook

In terms of regions, the market has been segregated into North America, Europe, Asia Pacific, Latin America, and Middle East & Africa. Asia Pacific held a significant share of the market in 2019 and this trend is expected to continue during the forecast period. The share is attributed to the strong presence of metal processing companies, increasing scrap, and booming automotive sector. China dominates the induction furnace market in Asia Pacific; however, due to the ban on induction furnaces for the production of steel, the market in the country is expected to be hampered to a certain extent.

Competitive Landscape

- Key players in the market include Electrotherm, Danieli, SMS, Inductotherm Corporation, IHI, and OTTO JUNKER. These companies are considered as key manufacturers of induction furnace based on their revenue, regional presence, research & development (R&D) activities, and supply chain management system.

- These players are adopting key strategies such as acquisition, merger, and geographical expansion to strengthen their market position.

- In March 2017, Meltech completed the sale of its fourth induction furnace system to the Newby Foundries group. The foundry functions at a high utilization operating a two or three shift system, five days a week.

About Growth Market Reports:

GMR provides global enterprises as well as medium and small businesses with unmatched quality of “Market Research Reports” and “Industry Intelligence Solutions”. GMR has a targeted view to provide business insights and consulting to assist its clients to make strategic business decisions and achieve sustainable growth in their respective market domain. Our key analysis segments, though not restricted to the same, include market entry strategies, market size estimations, market trend analysis, market opportunity analysis, market threat analysis, market growth/fall forecasting, primary interviews, secondary research & consumer surveys.

Contact:

Growth Market Reports

Phone: +1 909 414 1393

Email: sales@growthmarketreports.com

Web: https://growthmarketreports.com

Follow Us: LinkedIn | Twitter

0