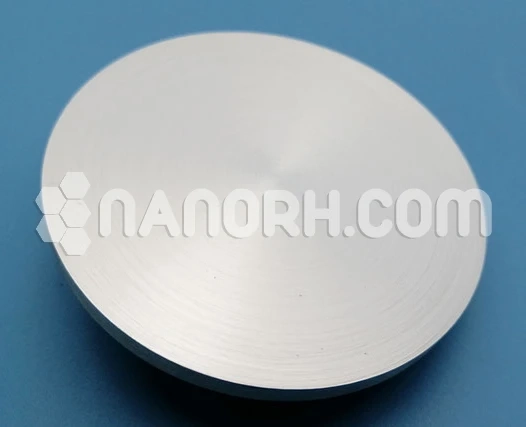

Sputtering targets are materials employed in the sputtering process, commonly used in the production of thin films. In sputtering, atoms from the target material are dislodged and deposited onto a substrate, creating a thin film. Typically composed of metals or compounds like oxides, nitrides, or carbides, these targets are carefully chosen to impart specific properties to the resulting thin film, such as conductivity, transparency, or hardness.

How do various industries employ sputtering targets?

Sputtering targets find widespread application across industries for depositing thin films onto diverse substrates. In the semiconductor sector, they are crucial for manufacturing integrated circuits and solar cells. The automotive industry utilizes these targets to coat components with wear-resistant films, enhancing durability. Moreover, in the medical field, sputtering targets are employed to create bioactive coatings on medical implants, improving their biocompatibility.

What is the process of manufacturing sputtering targets?

The production of sputtering targets involves several key steps:

Material selection and purification to ensure high quality and purity.Melting and casting the material into a solid form, typically a cylindrical ingot.Machining the ingot into the desired target shape, such as a disc or rectangular plate.Conducting quality control tests to ensure dimensional accuracy and purity.Packaging and shipping the sputtering target to customers for use across industries.What is the typical lifespan of sputtering targets?

Sputtering targets generally last for several hundred hours of continuous use. However, their longevity can vary based on factors like the material being sputtered, power and pressure settings, and overall target quality. Regular maintenance, including cleaning and inspections for wear and tear, can contribute to extending their lifespan.

How are sputtering targets installed and maintained?

Installing a sputtering target involves carefully following the manufacturer's instructions. Typically, the target is placed in a chamber, secured in a target holder, and the chamber is evacuated. Proper power and pressure settings are then applied. Maintenance includes regular cleaning to eliminate contaminants and inspecting for signs of cracking or pitting. Handling the targets with care is crucial to prevent physical damage.

In conclusion, sputtering targets play a pivotal role in various industries, and understanding their frequently asked questions aids in informed decision-making. These targets are vital for thin film production, with their meticulous selection and manufacturing ensuring the desired film characteristics. By comprehending the properties and materials involved, manufacturers can effectively produce high-quality thin films for applications in electronics, optics, and energy. Sputtering targets, offering a versatile method for depositing thin films, are reliable tools for diverse industrial applications due to their quality and effectiveness.

Source: https://havily.com/interesting-facts-you-need-to-know-about-sputtering-targets/