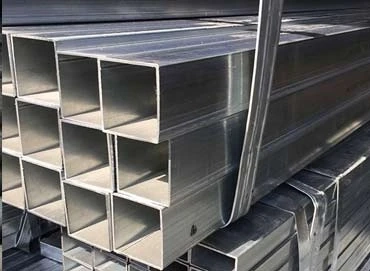

Steel IS 4923 Grade YST 310 Pipes are available from Hollow Section. which is a comprehensive supplier. Contact us right away if you are interested in purchasing pipes of a very high quality at costs that are extremely affordable.

Application and specification of IS 4923 YST 240 Cold Formed RHS Tubes

IS4923 That Was Formed in Cold The term "YST240 RHS" refers to a rectangular hollow section (RHS) that is manufactured out of cold-formed steel and complies with Indian Standard IS 4923. The YST240 designation denotes that the minimum yield strength of the steel used in the RHS is 240 MPa (240 MPa), and this value may be found in the designation. The production of cold-formed steel sections involves the cold-forming of steel sheets or strips into shapes that are analogous to RHS. The steel is shaped during the process at room temperature, and no heat is used at any point. This results in a product that is both more durable and more robust than the conventional hot-rolled steel pieces. IS 4923 is the Indian Standard for hollow steel sections for use in structural applications. This standard outlines the specifications for carbon steel that has been cold-formed into RHS, SHS (square hollow sections), and CHS (circular hollow sections). The standard calls for the use of multiple grades of steel, one of which, YST240, is designed specifically for use in structural applications that demand a high level of strength.

It is available in three classes, and each one has a composition and set of attributes that are distinct from the others depending on the ISO requirements, with a maximum of 0.12%. carbon, 0.03% to 0.08% silicon, 0.50% maximum manganese, 0.05% phosphorus, and 0.05% each of silicon and silicon. It is consistent with a certain minimum. Minimum tensile strength of 450 MPa or more. Maximum tensile strength of 310 MPa with a minimum. Raise the percentage for sizes between 25.4 and 8, as well as sizes between 25.4 and 10.

for more information you can contact us