hat are Titanium Sheets?

Titanium is a fantastic alloy composed of iron and a few other metals. Titanium is a chemical alloy with a chemical composition of 6% aluminum, 4% vanadium, 0.5% iron, and 0.2% oxygen. The spectacular properties of titanium are due to the precise proportions of these metals and chemicals. One of the best characteristics of this alloy is its high tensile strength. Titanium is lighter and more corrosion resistant due to the presence of aluminum. Titanium can withstand a wide range of temperatures and environmental conditions.

Because titanium is more expensive than other metals, it is primarily used in military and medical applications. The solid solubility of the alloy varies dramatically with temperature, allowing it to be strengthened through precipitation. This heat treatment is applied after the alloy has been worked into its final shape but before it is used, making the fabrication of a high-strength product much easier.

What are Titanium Grade 2 Sheets?

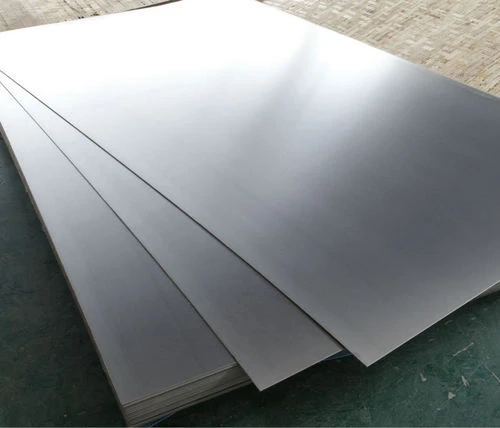

Titanium alloy Grade 2 contains 0.20 percent iron, 0.08 percent carbon, and 0.18 percent oxygen. Grade 2 has a tensile strength of 49900 Psi, yield strength of 39900 Psi, an elongation of 20%, and a melting point of 1665 C. Titanium Grade 2 Sheets would meet the following specifications: ASTM B265 / ASME SB 265 / AMS 4940, and would be available in sizes ranging from 8mm to 100mm. Grade 2 can be forged into a sheet, plates, coils, flat, strips, profile, blank, circle, ring, and other shapes.

A sheet is just that: a metal sheet. The thickness of the sheet is limited, but it is not as thick as a plate. A sheet is much thinner than a plate, whereas a plate is similar to a sheet but much thicker, indicating the difference between the two. Shim sheets are simply sheets made of any metal that come in a variety of colors, textures, and patterns. Because it is stronger and more durable, titanium Grade 2 makes excellent sheets, plates, and shim sheets. As a result, these sheets, plates, and shim sheets can all be used outside or exposed to the elements.

Applications of Titanium Grade 2 Sheets

Titanium Grade 2 sheets, plates, and shim sheets are used in a variety of industries. The Oil & Gas Industry, Petrochemicals Plants, Chemical Plants, Industrial Machinery, Power Industry, Paper & Pulp Industry, Food Processing Industry, and Refineries are the industries that use these products the most. Sheets and plates are used for a variety of purposes in this location.

The Sheets are widely used for a variety of purposes. Titanium Grade 2 plate is widely used in the automobile manufacturing industry to provide the strength and quality required for crash testing. Furthermore, Grade 2 sheets are used in the aviation and transportation industries.

It includes fundamental areas for ships, military vehicles, railroads, and trucks. Alloy sheets, also known as Cold Rolled Products, can be shaped to make cookware such as grills, sinks, pots, and cookers.