In the intricate landscape of fluid management across industries, the role of dosing pumps stands out as a critical element in achieving precision, efficiency, and control. From pharmaceuticals to water treatment, the versatility and reliability of Dosing Pump have positioned them as indispensable tools. This comprehensive guide delves into the world of dosing pumps, exploring their mechanisms, applications, and the transformative impact they have on various industrial processes.

Understanding Dosing Pumps:

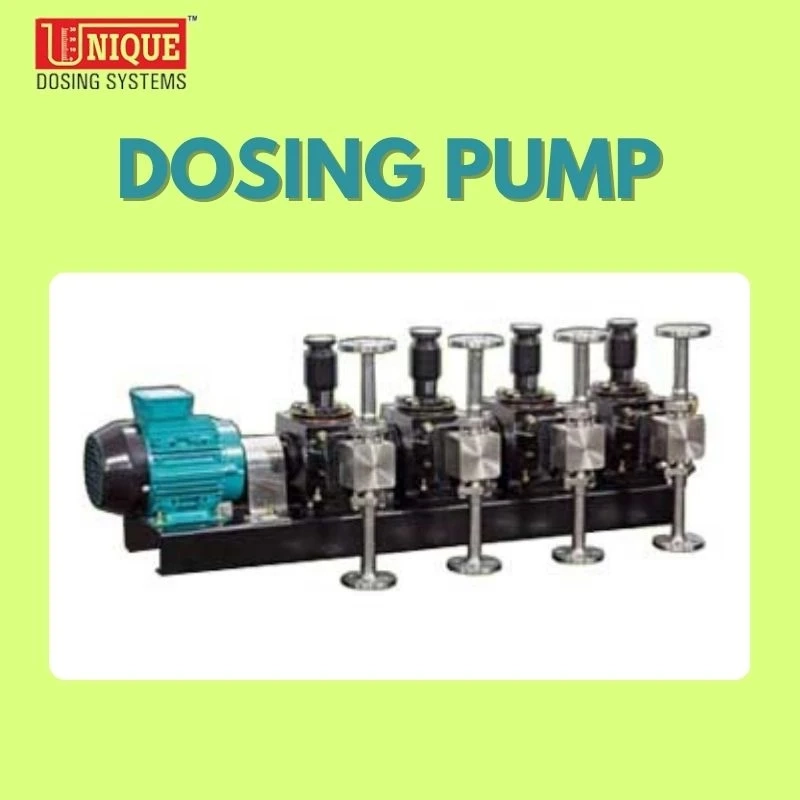

Dosing pumps are specialized devices designed to accurately dispense precise volumes of liquids or chemicals. These pumps operate on the principle of positive displacement, ensuring a consistent flow rate regardless of changes in pressure or viscosity. The core components of a dosing pump typically include a pump head, a motor or drive mechanism, and a control system that regulates the dosing process.

Types of Dosing Pumps:

Diaphragm Dosing Pumps:

Diaphragm dosing pumps utilize a flexible diaphragm to create a pumping action. This design is particularly advantageous for dosing corrosive or abrasive substances, as the diaphragm acts as a barrier, preventing contact between the fluid and the pump components. Diaphragm dosing pumps are widely used in chemical processing and water treatment applications.

Peristaltic Dosing Pumps:

Peristaltic pumps employ a rotating mechanism to compress and decompress a flexible tube, creating a pulsatile flow of fluid. These pumps are known for their ability to handle a wide range of viscosities and are commonly used in pharmaceutical and food processing industries where hygienic conditions are paramount.

Plunger Dosing Pumps:

Plunger pumps operate by using a reciprocating plunger to displace fluid. These pumps are valued for their high-pressure capabilities, making them suitable for applications such as injecting chemicals into pressurized systems or controlling the flow of liquids in industrial processes.

Benefits of Dosing Pumps:

Accuracy and Precision:

Dosing pumps excel in providing accurate and precise dosing, minimizing the risk of errors and ensuring consistency in processes.

Efficiency and Cost Savings:

By delivering precise volumes of substances, Dosing Pumps contribute to operational efficiency, reducing waste and lowering overall production costs.

Flexibility and Customization:

Many dosing pumps come equipped with user-friendly interfaces, allowing operators to customize dosing parameters based on specific requirements. This flexibility enhances adaptability to varying production needs.

Reliability and Consistency:

The consistent dosing provided by these pumps enhances overall product quality, ensuring that end products meet regulatory standards consistently.

Reduced Environmental Impact:

Dosing pumps contribute to sustainability efforts by minimizing waste and preventing the overuse of chemicals, thus reducing the environmental impact of industrial processes.

Challenges and Considerations:

While Dosing Pump offer numerous advantages, it's essential to consider factors such as maintenance requirements, compatibility with different substances, and the need for periodic calibration. Regular maintenance and adherence to manufacturer guidelines are crucial to ensuring the longevity and optimal performance of dosing pumps.

Conclusion:

Dosing pumps represent a cornerstone in the landscape of industrial fluid management, embodying precision, reliability, and efficiency. Their application spans across diverse industries, contributing to the production of high-quality pharmaceuticals, the purification of water, and the precise formulation of chemical products. As technology continues to advance, dosing pumps will play an increasingly pivotal role in shaping the future of industrial processes. Mastering the intricacies of dosing pumps is key to unlocking their full potential and harnessing the benefits they bring to the ever-evolving world of fluid management.

Visit: https://www.uniquedosing.com/dosing-pump.html

Contact: +91-9822420535