In today’s age of innovation and precision, industries demand heating solutions that are compact, efficient, and reliable. Polyimide flexible heaters have emerged as one of the most advanced options for applications requiring precise temperature control, flexibility, and durability. These ultra-thin heaters provide consistent thermal performance even in challenging environments — making them a popular choice in electronics, aerospace, medical, and automotive sectors.

What Are Polyimide Flexible Heaters?

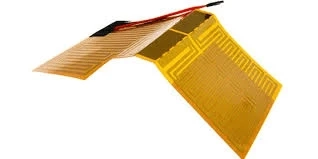

Polyimide flexible heaters are thin, lightweight heating elements made from a polyimide film (such as Kapton®) that encapsulates etched-foil resistive circuits, usually made of copper or nickel. The result is a highly durable and flexible heater that can deliver uniform heat across flat or curved surfaces.

Polyimide, known for its excellent dielectric strength and heat resistance, allows these heaters to operate efficiently in extreme conditions — from cryogenic temperatures to around 200°C. Despite their thinness, they maintain outstanding thermal stability, making them suitable for delicate devices and compact systems.

How Do Polyimide Flexible Heaters Work?

The working principle of polyimide flexible heaters is straightforward yet highly efficient. When electrical current passes through the resistive circuit, it generates heat through electrical resistance. The polyimide film evenly distributes this heat while protecting the internal components from oxidation, moisture, and chemicals.

Because of their uniform heating capability, these heaters ensure stable temperatures without hot spots or uneven heating. They can be powered by both AC and DC sources, and can easily integrate with temperature sensors or controllers for precise thermal regulation.

Key Features and Advantages

- Ultra-Thin and Lightweight Design:

- With a thickness typically below 0.2mm, polyimide flexible heaters can be easily integrated into compact systems without adding bulk or weight.

- High Flexibility:

- Their bendable nature allows installation on curved, irregular, or moving surfaces without compromising heating performance.

- Excellent Heat Transfer Efficiency:

- The etched-foil design ensures rapid and uniform heat distribution, minimizing energy loss.

- Chemical and Moisture Resistance:

- The polyimide layer protects against environmental factors like humidity, oils, and corrosion — ensuring longer lifespan and reliability.

- Wide Operating Temperature Range:

- Suitable for both low-temperature and high-temperature applications, ranging approximately from -200°C to +200°C.

- Precision Temperature Control:

- These heaters can be paired with thermistors, RTDs, or thermostats for highly accurate thermal management.

Applications of Polyimide Flexible Heaters

The versatility of polyimide flexible heaters makes them suitable for various industrial and commercial applications, including:

- Electronics: For maintaining consistent temperatures in battery packs, sensors, and circuit boards.

- Aerospace: Used in satellite instruments, navigation systems, and de-icing mechanisms due to their lightweight and reliability.

- Medical Devices: Ideal for patient warming systems, diagnostic equipment, and fluid temperature regulation.

- 3D Printing & Laboratory Equipment: To ensure precise temperature control in printing beds, incubators, and analyzers.

- Automotive: Applied in mirror defogging, camera modules, and battery temperature maintenance systems.

Why Choose Best-Heaters for Polyimide Flexible Heaters

Best-Heaters is a trusted manufacturer specializing in high-quality polyimide flexible heaters designed to meet the most demanding industrial requirements. With advanced manufacturing technology and strict quality control, the company ensures excellent performance, safety, and durability in every product.

Each heater is customizable based on voltage, watt density, shape, and size — offering tailor-made thermal solutions for diverse industries. Best-Heaters’ products comply with international standards such as UL, ISO, RoHS, and REACH, ensuring global reliability and certification compliance.

Whether you need heaters for precision instruments, medical systems, or aerospace devices, Best-Heaters delivers solutions that combine performance, innovation, and long-term dependability.

Energy Efficiency and Sustainability

In addition to performance, polyimide flexible heaters contribute to energy efficiency and sustainability. Their fast response time and low power consumption reduce operational costs, while their long lifespan minimizes maintenance and replacement requirements. These qualities make them a smart choice for companies aiming to optimize efficiency while reducing environmental impact.

Conclusion

As industries continue to evolve toward smarter and more compact systems, polyimide flexible heaters stand out as a key technology enabling precise, efficient, and flexible thermal control. Their exceptional performance in harsh environments, combined with their durability and adaptability, makes them indispensable across multiple sectors.

For cutting-edge, customizable, and reliable polyimide flexible heater solutions, Best-Heaters continues to lead the way — powering innovation with precision heating technology built for the future.