PP corrugated sheets, also known as polypropylene corrugated sheets, are a versatile and lightweight plastic material finding increasing application across various industries. Their unique corrugated design offers a combination of strength, durability, and affordability, making them a compelling alternative to traditional materials like wood, metal, and cardboard. This article delves into the world of PP corrugated sheets, guiding you through material selection, applications, and frequently asked questions.

Understanding PP Corrugated Sheets

PP corrugated sheets are manufactured using polypropylene, a thermoplastic polymer known for its chemical resistance, high melting point, and recyclability. The manufacturing process involves extruding molten polypropylene into sheets, followed by forming corrugations that run through the thickness of the sheet. These corrugations provide structural rigidity, similar to the fluting found in cardboard, but with enhanced strength and water resistance.

Benefits of PP Corrugated Sheets

1. Lightweight: PP corrugated sheets are significantly lighter than traditional materials like wood or metal, making them easier to transport and handle. This translates to lower transportation costs and simpler installation.

2. Durability: Despite their lightweight nature, PP corrugated sheets offer impressive strength and impact resistance. They can withstand significant loads without deforming or breaking.

3. Water Resistance: Unlike cardboard, PP corrugated sheets are not susceptible to water damage. This makes them ideal for outdoor applications and environments with high humidity.

4. Chemical Resistance: PP corrugated sheets exhibit excellent resistance to a wide range of chemicals, including acids, alkalis, and oils. This opens doors for their use in industrial settings.

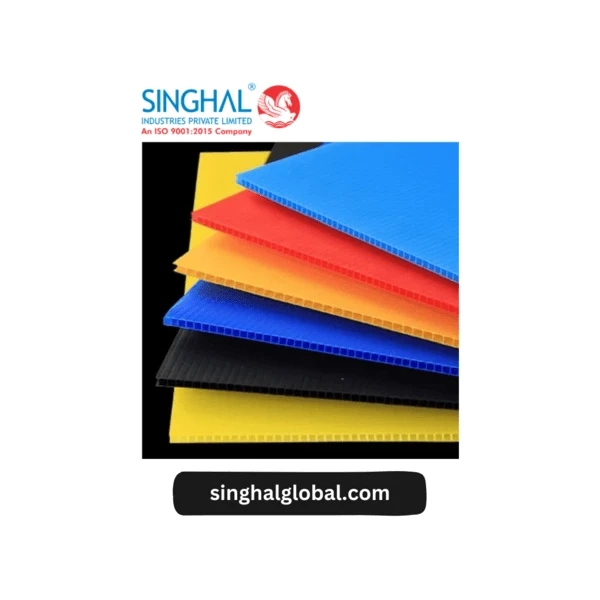

5. Versatility: PP corrugated sheets come in various thicknesses, sizes, and colors, allowing for customization to suit specific needs. Additionally, they can be easily cut, drilled, and shaped, facilitating on-site modifications.

6. Insulation: The air pockets created by the corrugations provide good thermal and acoustic insulation properties, making them suitable for applications requiring temperature or noise control.

7. Recyclability: Polypropylene is a recyclable plastic, and PP corrugated sheets can be reprocessed into new products, minimizing environmental impact.

Selecting the Right PP Corrugated Sheet

With the diverse range of PP corrugated sheets available, choosing the right one for your project requires careful consideration. Here are some key factors to keep in mind:

1. Thickness: Sheet thickness directly impacts its strength and load-bearing capacity. Thicker sheets offer superior sturdiness for demanding applications, while thinner sheets are ideal for lightweight projects.

2. Flute Size: The size and depth of the corrugations (flutes) influence the sheet\'s rigidity. Larger flutes provide greater structural support, whereas smaller flutes offer improved flexibility.

3. Surface Finish: PP corrugated sheets come in both smooth and textured finishes. Smooth finishes are aesthetically pleasing and easy to clean, while textured finishes provide better grip and slip resistance.

4. Color: PP corrugated sheets are available in a variety of colors, allowing you to match your project\'s aesthetics or enhance visibility for signage applications.

5. Additive Requirements: Depending on your specific needs, you may require sheets with UV protection for outdoor use, anti-static properties for handling electronic components, or fire retardancy for safety considerations.

Applications of PP Corrugated Sheets

The widespread popularity of PP corrugated sheets stems from their adaptability to numerous applications. Here are some prominent examples:

1. Signage and Displays: PP corrugated sheets are a cost-effective and lightweight alternative to traditional signage materials like wood or metal. Their printability allows for vibrant graphics and easy customization.

2. Packaging: PP corrugated sheets offer a durable and sustainable packaging solution for various products. They are perfect for protecting goods during transportation and storage, particularly for items sensitive to moisture.

3. Construction: PP corrugated sheets are increasingly used in the construction industry for temporary walls, roofing underlayment, concrete floor protection, and even prefabricated building components.

4. Agriculture: PP corrugated sheets find extensive use in greenhouses, providing a lightweight, translucent material for controlled environments. Additionally, they are used for crop protection, fencing, and signage within agricultural settings.

5. Automotive Industry: PP corrugated sheets are utilized for car part packaging, vehicle underbody protection during transport, and temporary workshop partitions.

6. Other Applications: PP corrugated sheets have numerous other applications, including partitions for trade shows and events, furniture components, protective flooring for exhibitions, and even creative DIY projects.

Finding the Right PP Corrugated Sheet Manufacturer

With the growing demand for PP corrugated sheets manufacturers offer this versatile material. When selecting a manufacturer, consider the following factors:

1. Product Range: Look for a manufacturer offering a diverse range of thicknesses, flute sizes, colors, and surface finishes to cater to your specific requirements.

2. Customization Options: Some manufacturers offer customization options like pre-cutting, printing, or adding specific additives to the sheets.

3. Reputation and Experience: Choose a reputable manufacturer with a proven track record of delivering high-quality PP corrugated sheets and excellent customer service.

4. Competitive Pricing: Compare quotes from several manufacturers to find one that offers the best value for your budget.

PP Corrugated Sheet Manufacturers in India

India boasts a thriving market for PP corrugated sheets, with numerous manufacturers catering to domestic and international needs. Here are some prominent PP corrugated sheet manufacturers in India (note: due to advertising restrictions, specific company names cannot be mentioned, but you can find them through online searches):

1. These manufacturers offer a wide range of PP corrugated sheets in various thicknesses, flute sizes, and colors.

2. Many Indian manufacturers are export-oriented, ensuring compliance with international quality standards.

3. It\'s recommended to research and compare offerings from various Indian manufacturers to find one that aligns with your project requirements and budget.

Conclusion

PP corrugated sheets offer a compelling combination of benefits, making them a versatile and cost-effective solution for various applications. By understanding their properties, considering key selection factors, and finding a reliable manufacturer, you can leverage the potential of PP corrugated sheets in your next project. With their continued development and growing popularity, PP corrugated sheets are poised to play an even more significant role in the future of sustainable and efficient material use.

Frequently Asked Questions(FAQs)

Q1. What is the temperature range for PP corrugated sheets?

A1. PP corrugated sheets typically have a usable temperature range from -10°C to +100°C. However, this can vary depending on the specific grade and additives used in the manufacturing process.

Q2. Can PP corrugated sheets be painted?

A2. While PP corrugated sheets can be painted, their smooth surface may require pre-treatment with a primer to ensure proper paint adhesion.

Q3. How long do PP corrugated sheets last?

A3. The lifespan of PP corrugated sheets depends on factors like exposure to sunlight, UV radiation, and mechanical stress. Under normal conditions, they can last for several years, especially when UV-stabilized grades are used outdoors.