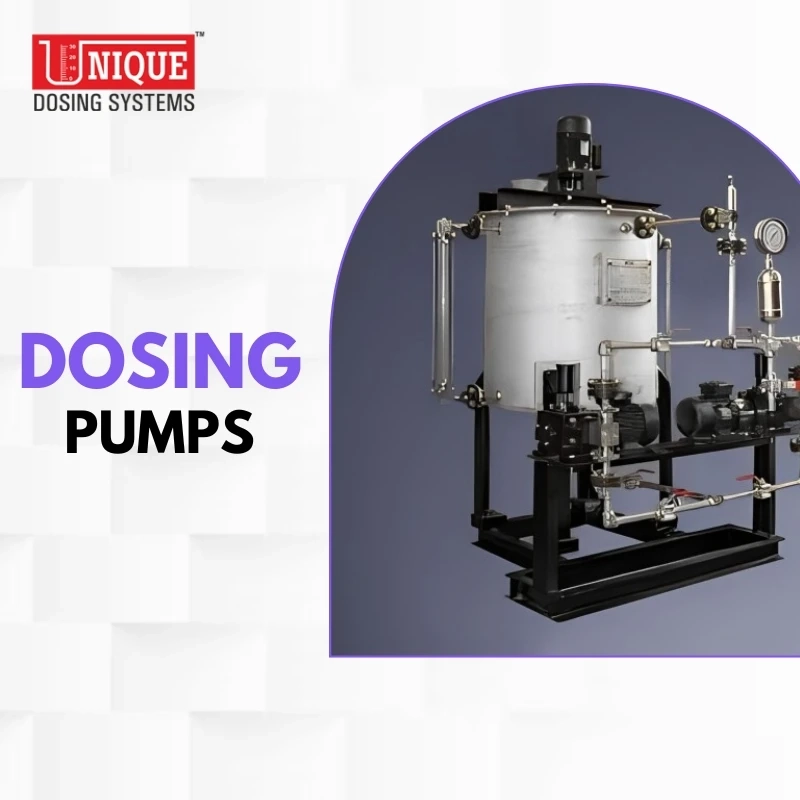

In the dynamic realm of industrial fluid management, the role of dosing pumps has emerged as a game-changer. These precision instruments have become integral to a diverse range of industries, ensuring accurate and controlled dispensing of fluids. In this guest post, we explore the significance of Dosing Pumps, their applications across sectors, and the transformative impact they have on industrial processes.

Understanding the Essence of Dosing Pumps:

Dosing pumps, at their core, are engineered to deliver precise volumes of fluids with consistency and reliability. This capability is crucial across industries where maintaining accurate dosing levels is imperative for operational efficiency, product quality, and compliance with regulatory standards.

Applications Across Industries:

The versatility of dosing pumps extends across various sectors, offering tailored solutions to distinct fluid management challenges. In water treatment facilities, dosing pumps are instrumental in adding chemicals for purification, ensuring water quality meets stringent standards. In the pharmaceutical industry, where precision is paramount, dosing pumps contribute to the accurate formulation of medications. Agriculture benefits from dosing pumps by facilitating the precise application of fertilizers and pesticides, optimizing crop yields while minimizing environmental impact.

Key Features and Functionalities:

Precision Engineering:

Dosing pumps leverage advanced technologies, such as peristaltic or diaphragm mechanisms, to maintain precise and consistent flow rates. This ensures that the desired volume is dispensed accurately, regardless of external variables.

Adaptability and Versatility:

One of the standout features of Dosing Pumps is their adaptability to a diverse range of liquids and applications. From corrosive chemicals to viscous fluids, dosing pumps can be configured to meet the unique requirements of each industry, providing a customizable and efficient solution.

User-Friendly Interface:

Modern dosing pumps come equipped with intuitive interfaces that simplify configuration and monitoring. Operators can easily set dosing parameters, monitor performance metrics, and make adjustments as needed, fostering a user-friendly and efficient operational environment.

Reliability in Harsh Environments:

The robust design of dosing pumps ensures durability and reliability, even in challenging operational conditions. Resistant to corrosion and wear, these pumps are built to withstand the demands of industrial processes, contributing to prolonged operational lifespans.

Cost-Efficiency:

Dosing pumps play a pivotal role in optimizing resource utilization. Their precise dosing capabilities result in reduced waste and minimized excess chemical usage, translating into tangible cost savings over time.

The Business Benefits:

The incorporation of dosing pumps into industrial processes offers a myriad of advantages for businesses:

Enhanced Accuracy and Product Quality:

Dosing pumps eliminate the inherent variability associated with manual dosing, ensuring consistent and accurate dispensing. This contributes to improved product quality, particularly in industries where precision is paramount.

Streamlined Operations:

The automation and precise control afforded by Dosing Pump streamline operations, reducing the need for manual intervention. This not only enhances overall efficiency but also allows personnel to focus on more intricate tasks.

Environmental Responsibility:

Dosing pumps contribute to environmental sustainability by minimizing excess chemical usage and reducing waste. This aligns with the growing emphasis on responsible industrial practices and compliance with environmental regulations.

Long-Term Cost Savings:

The cost-effective nature of dosing pumps, driven by reduced waste and optimized resource utilization, translates into tangible financial benefits for businesses over the long term.

Conclusion:

In conclusion, dosing pumps have evolved into indispensable tools, revolutionizing fluid management in industrial settings. Their precision, adaptability, and cost-efficiency make them a valuable asset across diverse industries. As businesses increasingly prioritize accuracy, efficiency, and environmental responsibility, Dosing Pumps are set to play an even more significant role in shaping the future of industrial fluid dispensing. Embrace the transformative power of dosing pumps and elevate your fluid management processes to new heights.

Visit: https://www.uniquedosingsystem.com/dosing-pump-manufacturers.php

Contact: +91 9822420535