Polyvinyl chloride (PVC) is one of the most widely used plastic materials in the world, valued for its versatility, durability, and cost-effectiveness. From construction and automotive to packaging and healthcare, PVC is embedded in our everyday lives. However, it’s the inclusion of additives that truly unlocks PVC’s potential—enhancing its performance, processability, and lifespan. As industries demand more efficient, flexible, and sustainable solutions, the PVC additives market is gaining remarkable momentum.

Additives play a critical role in tailoring the characteristics of PVC for specific applications. Without them, raw PVC would be brittle and unsuitable for many of the uses we take for granted. The expanding scope of applications and advancements in additive technologies are propelling the global PVC additives market into a new era of growth and innovation.

Free Copy: https://www.stellarmr.com/report/req_sample/PVC-Additives-Market/2471

What Are PVC Additives?

PVC additives are substances blended with raw PVC resin to modify or enhance its physical, chemical, and processing properties. These additives ensure that PVC materials meet the specific demands of various end-use industries. Common types of additives include:

- Stabilizers: Protect PVC from heat and UV degradation during processing and usage.

- Plasticizers: Increase flexibility and softness, especially in applications like cables, films, and synthetic leather.

- Impact Modifiers: Improve toughness and resistance to cracking or breaking under stress.

- Lubricants: Aid in processing by reducing friction during extrusion or molding.

- Fillers and Processing Aids: Enhance mechanical strength or reduce production costs.

- Flame Retardants: Increase fire resistance for safety-critical applications.

The correct combination and proportion of these additives are essential to ensure the desired performance in different applications.

Free Copy: https://www.stellarmr.com/report/PVC-Additives-Market/2471#

Market Growth Drivers

1. Rising Demand from the Construction Industry

PVC is a staple in the construction sector, used in pipes, window profiles, flooring, roofing membranes, and insulation. As urbanization and infrastructure development continue globally, especially in emerging economies, the demand for durable and cost-effective PVC products—and the additives that make them viable—is steadily increasing.

2. Expanding Use in Automotive and Electrical Applications

Lightweight, corrosion-resistant, and affordable, PVC is extensively used in automotive interiors, wire insulation, and electrical conduit systems. Additives enhance its heat resistance, flexibility, and strength, making PVC ideal for demanding environments.

3. Shift Toward Sustainable and Lead-Free Additives

Environmental concerns and regulatory pressures are driving the industry away from traditional lead-based stabilizers toward calcium-zinc and tin-based alternatives. This shift is boosting innovation and opening opportunities for eco-friendly additive formulations that meet safety and performance standards.

4. Advancements in Polymer Processing Technologies

Modern extrusion and injection molding techniques require additives that can perform under high-speed, high-temperature conditions. The development of specialized processing aids and lubricants is enabling manufacturers to improve efficiency and reduce energy consumption.

5. Increasing PVC Applications in Healthcare and Packaging

The medical industry uses flexible PVC in IV bags, tubing, and medical-grade containers, while the packaging industry utilizes it for films, blister packs, and containers. These applications demand high-performance additives that ensure safety, compliance, and long shelf life.

Market Segmentation

The PVC additives market can be segmented based on:

- Type: Stabilizers, plasticizers, lubricants, impact modifiers, processing aids, flame retardants, and fillers.

- Form: Powder, liquid, and pellets.

- End-Use Industry: Building & construction, automotive, electrical & electronics, packaging, healthcare, and consumer goods.

- Region: North America, Europe, Asia-Pacific, Latin America, Middle East & Africa.

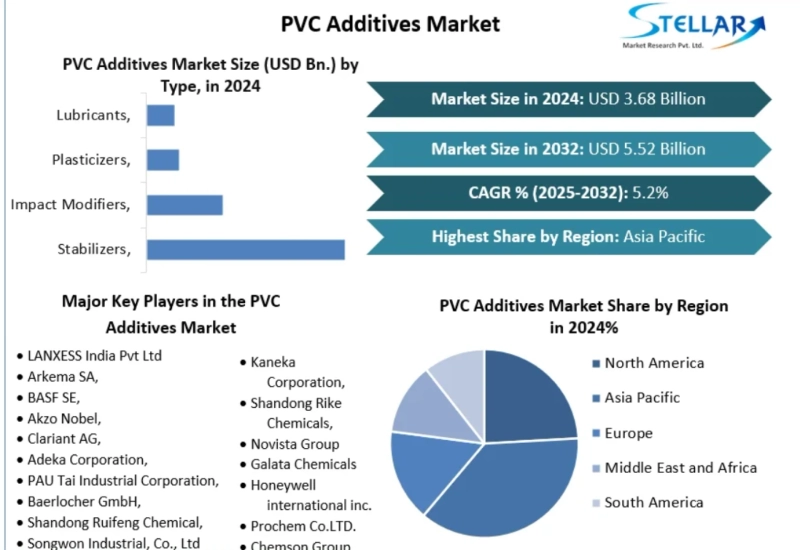

Among these, stabilizers and plasticizers account for the largest market share, given their widespread use across multiple sectors.

Regional Insights

- Asia-Pacific is the largest and fastest-growing market, driven by massive infrastructure projects, rapid industrialization, and a thriving manufacturing base in countries like China and India.

- North America and Europe are mature markets emphasizing high-performance and environmentally friendly additives, with strong demand in automotive and construction.

- Latin America and Middle East & Africa are emerging markets where increasing construction activity and urban development are driving PVC usage and, consequently, additive demand.

Challenges and Opportunities

Challenges:

- Environmental and Regulatory Compliance: Restrictions on toxic additives, such as phthalates and heavy metals, require manufacturers to invest in R&D for safer alternatives.

- Price Volatility of Raw Materials: Fluctuating oil prices and supply chain disruptions can impact the cost of producing certain additives.

- Compatibility Issues: Not all additives work well with all types of PVC or manufacturing processes, making formulation precision critical.

Opportunities:

- Green and Bio-Based Additives: Growing interest in sustainable materials is driving research into plant-based plasticizers and biodegradable stabilizers.

- Smart Additives: Development of additives with multifunctional benefits (e.g., UV resistance, antimicrobial properties) presents new product possibilities.

- Customization and Innovation: Tailored additive solutions that meet specific performance criteria for niche applications offer a competitive edge.

Future Outlook

As industries look for cost-effective, high-performance, and environmentally friendly materials, the role of PVC additives will only become more significant. The future of the market lies in innovation, sustainability, and customization. Companies that can balance performance with environmental responsibility will lead the way in redefining what's possible with PVC.

From construction to healthcare, PVC additives are the unseen drivers behind some of the world’s most essential products. With continued investment and technological progress, the PVC additives market is well-positioned to meet the growing demands of a rapidly changing world.

About us:

Established in 2018, Stellar Market Research is India Based consulting and advisory firm focused on helping clients to reach their business transformation objectives with advisory services and strategic business. The company’s vision is to be an integral part of the client’s business as a strategic knowledge partner. Stellar Market Research provides end-to-end solutions that go beyond key research technologies to help executives in any organization achieve their mission-critical goals.

Address

Phase 3, Navale IT Zone, S.No. 51/2A/2, Office No. 202, 2nd floor, Near, Navale Brg, Narhe, Pune, Maharashtra 411041

sales@stellarmr.com

Mobile

+91 9607365656