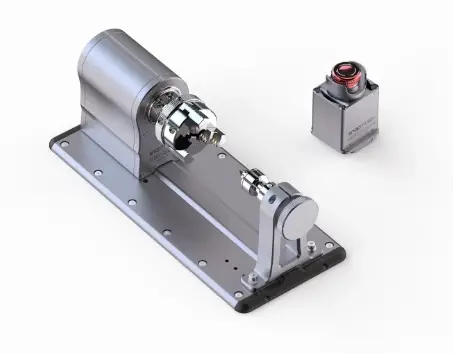

The Snapmaker 2.0 rotary module comes with very great features that are responsible for making the Snapmaker a very powerful CNC device. It has been characterized by the production of a three-dimensional work of art together with the printing of desktop miniatures and small sculptures. With the help of the rotary module, you're sure to get craftsmanship of the greatest level. Some of the reasons for using the Snapmaker 2.0 rotary module are as follows.

- No loss of detail

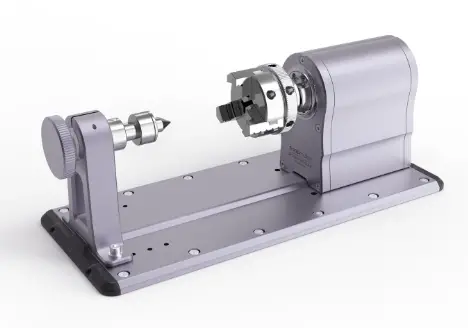

For the Snapmaker 2.0 rotary module, there is a 100:1 reduction gear that is converted to a lower output speed and a strain wave gear that is required. This gives room for the three-jaw chuck to have the ability to rotate at a minimum angle of 0.1 degrees, giving you the advantage of working on irregular surfaces and even uneven surfaces without missing a single step.

- Precise control

When the Snapmaker 2.0 rotary module is used, there is a continuous angle rotation of 360 degrees with an angular of 45 degrees per second in making the fastest sculptor. This type of rotary module has very precise control of 0.2, 1, and 5-degree rotation on the touchscreen, giving you the ability to see the difference in every motion that takes place.

- Multi-material and 4-axis project generation

The Snapmaker 2.0 rotary module supports dozens of materials such as wood, plastic, and leather, just to mention a few. This gives you the freedom to choose the type of material you want to use for your design, giving you the opportunity to make different prints. Snapmaker 2.0 rotary module has the ability to generate 4-axis projects directly with free Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) software that will help you to create designs easily from scratch to the finished product.

- Ability to carve hollow objects

When it comes to carving, there are objects that are very hollow, and at the same time, their outer shells are not equally shaped. It is very difficult to make the desired curves from such objects. However, when you have a Snapmaker 2.0 rotary module, it has software that does an important job of carving hollow objects and unequally shaped outer shells. For the rotary module to have complete control, there is 4-axis connection support that enables the X, Y, Z, and B axes to move together and at the same time.

- Safety

When you are carving, something might go wrong. The Snapmaker 2.0 Emergency Stop Button has been installed where you get to press in case something goes awry. It has been designed to provide an extra layer of safety when you're doing laser engraving and CNC carving by simply pressing the stop button when there is an emergency, and your operation comes to a halt, giving you the opportunity to fix the issue and start the process again instead of causing damage.

In addition, purchasing a Snapmaker rotary module is the best step you'll be making because it will be an important part of your career creation. It is equipped with 4-axis rotary milling cutter and laser engraving giving it the ability to be compatible with different materials. Before you choose the one to buy, check whether the price is something you can easily afford. The reputation of the company from where you are buying is another thing that you should take into consideration. Go through the customer reviews to be able to get more information on the company and the product itself to see whether it's something that has got positive reviews from other customers.