Industrial usage requires a constant supply of dry air, and it's nearly hard to get it from the atmosphere. Moisture-sensitive gear might be damaged if compressed air is not properly dehumidified before it is used in industrial processes.

What exactly is a Desiccant Air Dryer, and how does it work?

High-quality desiccant material is used in the manufacture of desiccant air dryers, which are ideal for applications requiring exceptionally low dew points. As a result, regenerative desiccant air dryers are often constructed as a pair of towers, with one tower drying the compressed air while the other tower is regenerating. If you monitor the dew point at the desiccant dryer's outlet, you can regulate the regeneration process more effectively by only regenerating when necessary.

How Does Desiccant Work?

Adsorbent substance desiccants have extremely high compatibility with water. The hygroscopic qualities of this unique substance allow it to sustain a dry atmosphere by attracting and retaining water molecules.

These dryers are utilized in compressed air systems that require dew points lower than those that refrigerated dryers can achieve. Industrial desiccant dryers come in three varieties: heatless, heated, and blower purge.

Heatless Regenerative Air Dryers

It is recommended that these dryers be used with lower airflow rates, higher intake temperatures, and extremely low dew points. The media bed is regenerated using compressed air that has been expanded, also known as purge air. This procedure uses 15 to 20 percent of the dryer's nominal capacity to regenerate.

Heated purge regenerated dryers

With the help of an electric air heater, these dryers warm up the expanded purge air to a comfortable temperature. They utilize about a quarter of the energy of heatless dryers while only requiring about a tenth of the purge flow.

Blower regenerated dryers

To rehydrate the desiccant, a fan blows outside air over an electric heater. This moistens the desiccant. Energy consumption is reduced by 40% when using this dryer type since compressed air isn't utilized to replenish the desiccant material.

For many plants, only regenerative desiccant air dryers can fulfill their needs. It's a sad fact that too many people base their choice of the regenerative dryer only on the price tag at the time of purchase. This choice does not take into account the cost of operating the dryer. Including the cost of energy in a buying decision can have a significant impact.

Conclusion

To dry compressed air, desiccant dryers employ a medium of desiccant. Desiccant media adsorbs moisture from the air as it travels through the desiccant medium. After a limited amount of moisture absorption, the desiccant medium must be dried out or regenerated. When this is done, the desiccant medium in the tower is depressurized and the water that has collected is pushed out using purge air, heat, or a good mix of both. There are two towers in a desiccant dryer, with one bed of desiccant in each tower. During the regeneration process, one bed might be used to dry compressed air.

The Best Place To Buy A Regenerative Desiccant Air Dryer

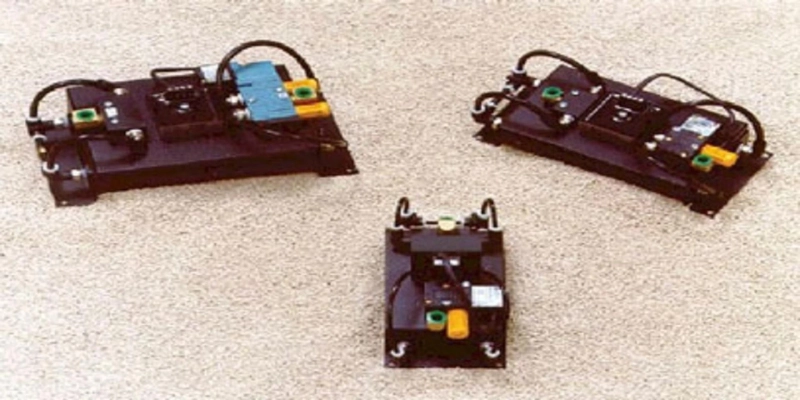

Air & Vacuum Process INC., provides a great selection of Aircel Heatless Desiccant Air Dryers in several price ranges—each of which is entirely dependent on your requirements. AHLD E-Series Aircel Desiccant Dryers include an integrated Energy Management System (EMS) for purging reduction while still being dependable and fully automated desiccant dryers. These dryers are the most dependable heatless dryers on the market because of creative engineering and technologically superior, very durable components.

Heatless Desiccant Air Dryers from Aircel may be put up fast and take up less floor space because of the ready-to-install style available at AVP. Take a look at their offerings right now by going to their website.

For more information about Portable Compressed Air Dryers and Air Compressor Drain Valve Please visit: Air & Vacuum Process Inc.