A welding power is equipment that supplies an electrical current to do the welding operation and sometimes uses a high current, usually over 80 amps. If you’re considering stocking welding equipment for customers then there are a few basic items your customers will expect and require. Are you looking to purchase some sort of welding equipment? Are you aware of the different types with this form of apparatus?.

Inside Convenient WHT machine Methods

WHT machine

Ost weld heat treatment machine

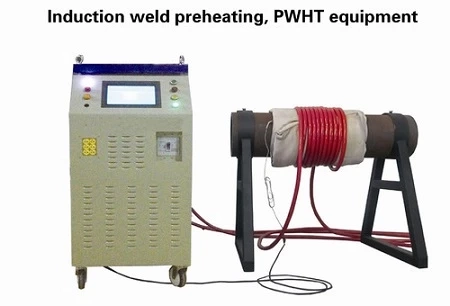

Induction pwht machine

Weld preheat machine

Induction post weld heat treatment machine

Other features comprise parts-in-place indicators, line voltage compensation, and thermostatic protection. The most intricate machine designs may be accomplished with these two processes. Thus, it ensures different work patterns and outputs. Including these with your range will appeal to the more experienced customers who demand ultra high spec equipment to complete the job. Whatever decision you’re making, when you find yourself comparing welding machines on the market just make sure that you don’t let yourself get scammed.

The current is often as high as 12000 amps, which can be required for spot welding. Power supply equipment incorporates a transformer, generator, and alternator and inverter. This means WHT machine you should think about factors such as the kind of metal you’ll be welding, how thick it can be, where the weld will probably be, the roughness with the material and just how long you have available to invest in your welding. Most operators are aware that MIG welders join metals faster than TIG welders. But, TIG welders produce greater degree of precision, so needed for certain varieties of jobs. Whether you might be an OEM or even a contract manufacturer, obtaining a competitive price for welding and fabrication services is essential.

The source useful for welding is dependent upon the work place. Scouting online can help you know the different varieties of welding, welders and welder equipment available available in the market. First you must look into the size of your project. Is it a large scale project or a small repair? Are you obtaining a profession or possibly this just your hobby?. You can select these models if you want mobility as these portable welders could be moved around with the aid of few wheeled accessories. MIG welders feed a constant stream of wire using a pull from the trigger. You must be additional cautious in choosing the consumables.

You never want to acquire something on the Internet and then not have the option to become able to return to the store. Thinking of starting a welding business? Then you have bigger concerns than simply buying welding supplies. One thing to note with this sort of Welding Equipment is that it really is typically best suited for thin sheets of metal – if you need to join thicker sheets then you might like to consider a different kind of welding machine which will do the position more successfully. Also you may want to have equipment which is multipurpose. For example a cutter and welder together will save you lots of space and cost rather than buying every person piece of apparatus.

If you are looking for pwht equipment, cmheat is the right place for you to find what really good for you.