The global 3D Metrology Market is estimated to be valued at $6,647.9 million by 2028, surging from $3,711.1 million in 2020, at a noteworthy CAGR of 7.8%

COVID-19 Impact on 3D Metrology Market

The COVID-19 outbreak caused a scarcity of staff and raw materials, affecting the majority of factories to close. The world is undergoing an economic crisis as a result of the COVID-19 pandemic. The pandemic, like other markets, has reduced the growth rate of the industrial 3D metrology market, mainly in 2020 and 2021. This is due to the fact that organizations in the majority of the foremost demand- creating verticals are currently, or were previously, non-operational in various countries, negatively impacting the 3D metrology market. The COVID-19 pandemic has affected industries on a large scale, and manufacturers are attempting to assess the impact. Lockdowns in the past and present have resulted in the shutdown of manufacturing facilities which has put a significant strain on the industrial sector.

Request Exclusive Free Sample @ https://www.researchdive.com/download-sample/8544

Global 3D Metrology Market Analysis

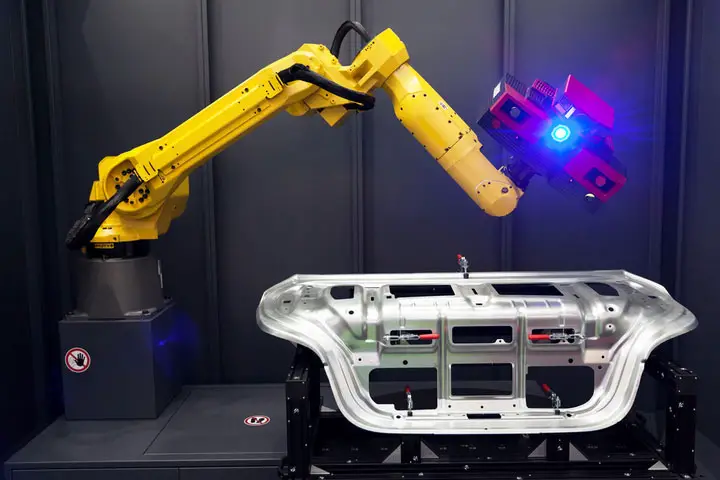

Demand for metrology in the global market is driven by a variety of factors. The drive in the market demand in the global market during the review period is due to a sudden increase in semiconductor inspection, energy harvesting, use of various high-tech robots serviceable in automation, and high demand for technically advanced devices used specifically for measuring. As many physical changes occur during the operational process, 3D metrology is widely used to measure the dimensions of objects. It is commonly used in rubber products because it has a tendency to change its technical and physical properties over time.

Despite the fact that the metrology market is growing at an incredible rate in the global market, some factors are limiting its growth. The lack of awareness about this technology, combined with a lack of expertise in technical departments in various emerging countries is impeding global market growth. In addition, the use of a metrology system for measuring equipment becomes prohibitively expensive for small and medium-sized businesses, limiting market growth.

Connect with our expert analyst to get more details@ https://www.researchdive.com/connect-to-analyst/8544

The increasing demand for 3D metrology is creating the opportunities of growth for the market. Increasing cloud service growth provides a broad scope for automating the manufacturing process, which provides various growth opportunities for the 3D metrology market forecast period. Various major key players, such as Carl Zeiss, Nikon, and FARO Technologies, also provide cloud services, which aid in the management of metrological data, resulting in increased demand during the review period. It will aid them in providing software solutions to their clients. Furthermore, the rapid adoption of cloud computing and Industry 4.0 are also boosting the growth of the market. The combination of CMM and IIoT allows manufacturers to exchange precise details of a workpiece via a cloud platform between facilities, customers, or suppliers in the supply chain, assisting other manufacturers in reducing manufacturing waste and minimizing production errors. Furthermore, the integration of CMM and Industry 4.0 allows manufacturers to track and optimize the supply chain, as well as obtain real-time data on production and product performance, allowing businesses to provide better services to customers and create new revenue streams. For example, ZEISS Group, a leading technology company, and Microsoft declared a multi-year strategic business in October 2020, to accelerate ZEISS' transformation into a provider of digital services through a cloud-first approach. ZEISS will be able to provide enhanced digital experiences to its customers, respond to shifting market requirements more quickly, and increase productivity by standardizing its equipment and processes in Microsoft Azure as its preferred cloud platform.

Global 3D Metrology Market, Segmentation

The global 3D metrology market is segmented based on offering, products, application, end-use, and region.

Offering:

The offering segment is further classified into software, hardware, and services. The hardware sub-segment is expected to have the largest market share, with revenues exceeding $2,582.0 million by 2028, up from $1,478.6 million in 2020. With technological advancements, dimensional metrology equipment has evolved tremendously over the last decade. To remain competitive, end-users want to reduce manufacturing errors and improve product quality. Accuracy is critical in the automotive, aerospace, and medical device industries: even minor flaws can have fatal consequences. The hardware sub-segment of the 3D metrology market accounted for a sizable share of the global market. This can be attributed to its increasing use in automotive design & styling, surface analysis, aircraft component inspection, and power train components.

Products:

The products segment is further classified into coordinate measuring machine (CMM), optical digitizer & scanner (ODS), video measuring machine (VMM), and 3D automated optical inspection (AOI) system. The CMM sub-segment is expected to have a dominant market share of $2,495.7 million by 2028, up from $1,467.0 million in 2020. Coordinate measuring machines (CMM) are devices that are used in 3D metrology to measure the physical geometrical properties of an object. The demand for the CMM will grow continuously due to the technology advancements for improved flexibility, ease of use, and simplicity of coordinate measuring machines capable of meeting inspection requirements. Coordinate measuring machines are used for inspection & measurement in industries such as automotive, aerospace, electronics, energy & power, and others.

Application:

The application segment is further divided into quality control & inspection, reverse engineering, virtual simulation, and others. The quality control & inspection sub-segment has a dominating market share and it is expected to surpass $2,565.9 million by 2028, up from $1,477.2 million in 2020. In manufacturing, 3D metrology is becoming an essential part of any quality control, optimization, and cost-effective process. With the growing demand for quality control, virtual simulations, and inverse engineering in the manufacturing industry, the demand for cutting-edge 3D metrology machinery in industries such as aerospace, defense, automotive, construction, electronics, and others has increased significantly.

End-use:

The end-use segment is further divided into aerospace, automotive, medical, construction & engineering, heavy machinery, and others. The automotive sub-segment has a dominating market share and it is expected to surpass $2,146.3 million by 2028, up from $1,253.1 million in 2020. Inspecting, measuring, and inspecting the quality of various tools, castings, plastic and sheet metal parts in assemblies, and vehicle bodies are parts of 3D testing for capturing detailed data and running full-field evaluations. Furthermore, strong growth of the metrology solutions in the automotive industry is propelling market expansion. 3D metrology is widely used for scanning and inspecting complex components, as well as digitally recreating scanned parts. Among other things, it is used for corrosion inspection, hail damage depth, fixture measurement, part archival, and tooling measurement.

Region:

The 3D metrology market share for the APAC region is projected to have the fastest growing market share. The market in APAC generated a revenue of $846.9 million in 2020 and is projected to reach up to $1,716.5 million by 2028. China, India, Taiwan, and Japan account for the majority of APAC demand due to growth in the electronics and automotive industries, particularly for calibration services. Increased R&D spending on 3D metrology, increased request for quality control & inspection applications, and a high adoption of the 3D metrology in Asia-Pacific industries are driving the 3D metrology market demand.

Key Players in the Global 3D Metrology Market

Some of the leading global 3D metrology market players are

- Hexagon

- FARO Technologies

- KEYENCE Corp.

- Jenoptik, Nikon Corp.

- Mitutoyo Corp.

- ZEISS Group

- KLA Corp.

- Perceptron

- Renishaw

- 3D Systems, Inc.

Along with the company profiles of the key players in the market, the report includes the Porter’s five forces model that gives deep insights into the competitive environment of the market.

Porter’s Five Forces Analysis for the Global 3D Metrology Market

Bargaining Power of Suppliers: Suppliers in the 3D Metrology market are few, and product dependence, availability of raw materials, and pricing give suppliers significant bargaining power. As a result, the bargaining power of suppliers is high.

Bargaining Power of Buyers: Buyers have low negotiating power because establishing a 3D Metrology requires a significant capital investment. However, the high cost of the technologies will prevent users from adopting them..As a result, the bargaining power of buyers is low.

Threat of New Entrants: Startups entering this market face high capital investment costs, labor costs, and must adhere to government regulations. As a result, the threat posed by new entrants is low.

Threat of Substitutes: There are other methods available in the market. A variety of inspection equipment is available in industry to capture the points on a surface that will predict manufacturing form error. However, the market demand for 3Dd metrology is constantly increasing.Therefore, the threat of substitutes is low.

Competitive Rivalry in the Market: To stay ahead of the competition, companies in the global 3D metrology market are focusing on strategies such as business expansion, technological innovations, and product advancements. As a result, the market's competitive rivalry is high.

Request for this Report Customization & Get a 10% Discount on this Report@ https://www.researchdive.com/request-for-customization/8544

Related Reports:

About Us:

Research Dive is a market research firm based in Pune, India. Maintaining the integrity and authenticity of the services, the firm provides services that are solely based on its exclusive data model, compelled by the 360-degree research methodology, which guarantees comprehensive and accurate analysis. With unprecedented access to several paid data resources, a team of expert researchers, and a strict work ethic, the firm offers insights that are extremely precise and reliable. Scrutinizing relevant news releases, government publications, and decades of trade data, and technical white papers, Research dive delivers the required services to its clients well within the required timeframe. Its expertise is focused on examining niche markets, targeting their major driving factors, and spotting threatening hindrances. Complementarily, it also has a seamless collaboration with the major Market aficionado that further offers its research an edge.

Contact Us:

Mr. Abhishek Paliwal

Research Dive

30 Wall St. 8th Floor, New York

NY 10005 (P)

+ 91 (788) 802-9103 (India)

+1 (917) 444-1262 (US) Toll

Free: +1 -888-961-4454

Email: support@researchdive.com

LinkedIn: https://www.linkedin.com/company/research-dive

Twitter: https://twitter.com/ResearchDive

Facebook: https://www.facebook.com/Research-Dive

0