Lithium mining has gained significant attention in recent years due to the rise of electric vehicles (EVs) and the rapid growth of e-mobility. However, the current methods of lithium extraction are proving to be energy- and mineral-intensive, raising concerns about their sustainability and environmental impact. As the world strives for reduced carbon emissions and a greener future through e-mobility, it becomes crucial to explore more sustainable and efficient approaches to lithium mining.

The Need for Sustainable Lithium Production

The EV industry in south Africa is witnessing a transformative shift, with major players like Volkswagen Group and Mercedes-Benz leading the way. These companies are reevaluating their value chains and actively seeking alternatives to traditional mining methods. The aim is to develop a more sustainable lithium production process that minimizes environmental footprint and can potentially replace conventional mining in the future.

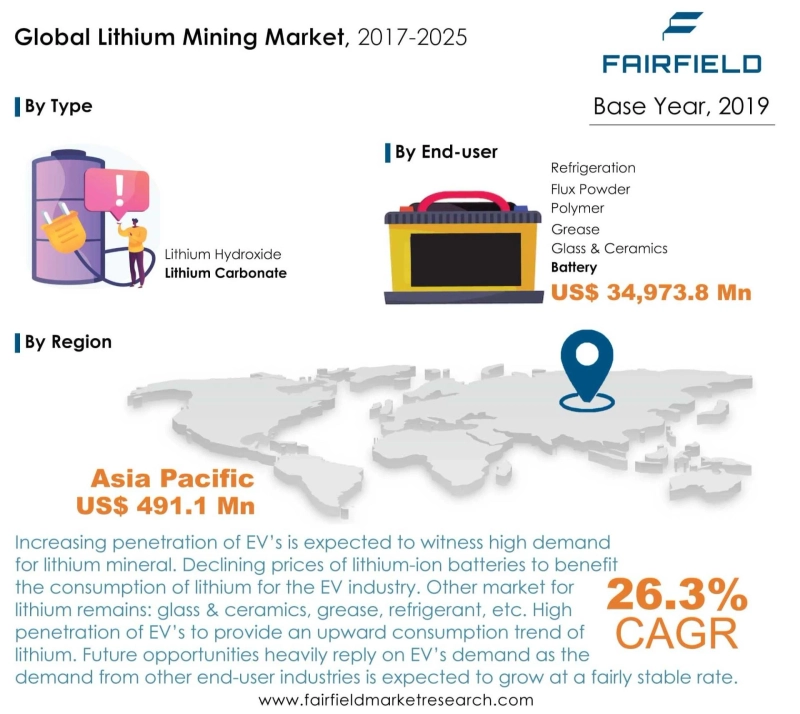

For more information, please refer to the full report: https://www.fairfieldmarketresearch.com/report/lithium-mining-market

Exploring Promising Alternatives

One promising avenue for sustainable lithium extraction is the use of geothermal brines. Research suggests that these brines could serve as a viable source for lithium recovery. By harnessing this natural resource, we can reduce the dependence on traditional mining methods and mitigate the environmental impact associated with them.

Additionally, the recycling of lithium from batteries and electronic devices is being considered as a viable option. However, the existing quantity of recycled lithium is not sufficient to meet the current global demand. According to the World Bank, if we consider the lithium consumption solely by EVs, we would need nearly five times the amount of currently mined lithium to achieve the global climate targets set for 2050.

Transitioning to a Circular Economy

While it is evident that lithium will remain a crucial raw material for electric cars in the coming decades, the majority of it is expected to come from recovered or recycled sources rather than new mining operations. However, the process of collecting and recycling a sufficient quantity of high-quality Li-ion batteries will take time and may not reach an optimal level until the end of this decade.

The shift towards a circular economy, where lithium-ion batteries are recycled and reused, holds great potential for reducing the demand for new mining operations. This transition will require collaboration between the EV industry, battery manufacturers, and recycling facilities to establish efficient collection and recycling systems.

Conclusion

The contentious angle of lithium mining presents both challenges and opportunities for the future of e-mobility. While the current mining practices raise concerns about environmental impact and resource depletion, the industry is actively exploring sustainable alternatives. From geothermal brines to the recycling of lithium batteries, various avenues are being pursued to ensure a more sustainable and efficient lithium production process.

As the demand for electric vehicles continues to grow, it becomes imperative to address the environmental concerns associated with lithium mining. By adopting innovative and eco-friendly practices, we can pave the way for a greener future of e-mobility.

Frequently Asked Questions

What is the significance of lithium in the context of electric vehicles?Lithium plays a crucial role in the manufacturing of lithium-ion batteries, which are the primary power source for electric vehicles. These batteries provide the necessary energy storage for EVs to operate efficiently.

Why is sustainable lithium mining important?

Sustainable lithium mining is essential to minimize the environmental impact associated with traditional mining methods. It allows for the extraction of lithium while reducing carbon emissions and preserving natural resources.

What are geothermal brines, and how can they be used for lithium recovery?

Geothermal brines are naturally occurring underground water reservoirs with high temperatures. They can be a potential source for lithium recovery, offering a more sustainable alternative to traditional mining.

How does battery recycling contribute to sustainable lithium production?

Battery recycling involves the collection and reprocessing of used lithium-ion batteries to extract valuable materials such as lithium. It helps reduce the demand for new mining operations and promotes a circular economy.

When can we expect a significant shift towards recycled lithium?

While the transition towards a significant reliance on recycled lithium will take time, it is expected to gain momentum by the end of this decade as the quantity and quality of recycled Li-ion batteries increase.

Read More: https://www.fairfieldmarketresearch.com/