The textile industry is a dynamic landscape, constantly evolving with new technologies and materials. In this ever-changing environment, staying ahead of trends is crucial for manufacturers and brands alike. One material that has captured significant interest in recent years is PP (polypropylene) multifilament yarn. This article delves into the world of PP multifilament yarn, exploring its properties, applications, and how it can empower you to stay at the forefront of textile trends.

Understanding PP Multifilament Yarn

PP multifilament yarn, also known as Polypropylene multifilament yarn, is a synthetic yarn composed of numerous individual filaments bundled together. Polypropylene, a thermoplastic polymer, offers several advantages that make it a compelling choice for various textile applications.

1. Durability: PP fibers are known for their exceptional strength and resilience. They are resistant to abrasion, tearing, and chemicals, making them ideal for applications requiring high performance.

2. Lightweight: PP is one of the lightest commercially available fibers, offering weight savings in textiles compared to traditional materials like cotton.

3. Water Resistance: Polypropylene exhibits excellent water repellency, making fabrics created with PP multifilament yarn quick-drying and moisture-wicking.

4. Cost-Effective: PP is a relatively inexpensive material, offering a cost-effective solution for various textile applications.

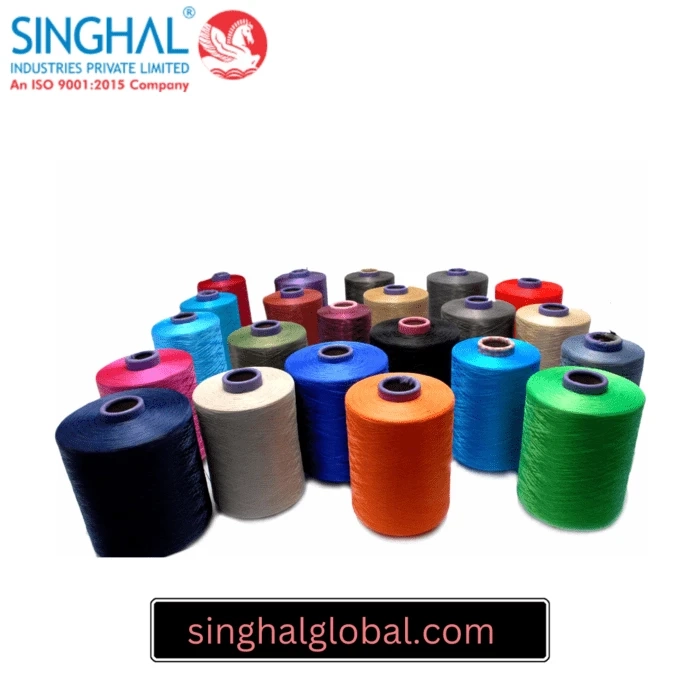

5. Versatility: PP multifilament yarn can be dyed in a wide range of colors, making it suitable for creating aesthetically pleasing textiles.

The "multifilament" aspect refers to the presence of multiple filaments within the yarn. This construction method enhances several properties of the yarn, including:

1. Strength: The combined strength of numerous filaments creates a more robust yarn compared to single-filament yarns.

2. Texture: The number and thickness of filaments can be manipulated to achieve different textures, from smooth and silky to bulky and textured.

3. Performance: Multifilament yarns can be engineered to offer specific performance characteristics, such as high breathability or improved wicking properties.

Applications of PP Multifilament Yarn

The versatility of PP multifilament yarn has led to its adoption across a wide range of textile applications. Here are some prominent examples:

1. Sportswear and Activewear: Due to its lightweight, breathable, and moisture-wicking properties, PP multifilament yarn is extensively used in sportswear and activewear apparel. It offers superior comfort and performance during physical activity.

2. Upholstery and Home Textiles: PP multifilament yarn\'s durability and stain resistance make it a suitable choice for upholstery fabrics and home textiles like carpets and rugs.

3. Industrial Fabrics: The strength and chemical resistance of PP multifilament yarn make it ideal for industrial applications like filtration fabrics, cargo straps, and geotextiles.

4. Packaging: PP multifilament yarn finds applications in creating woven bags and sacks for packaging due to its strength and water resistance.

5. Medical Textiles: The hypoallergenic nature and sterility of PP multifilament yarn make it suitable for specific medical textiles like surgical gowns and drapes.

Finding the Right PP Multifilament Yarn Manufacturer

The success of your textile project hinges on selecting a high-quality PP multifilament yarn manufacturer. Here are some key factors to consider when making your choice:

1. Product Range: Ensure the manufacturer offers a variety of PP multifilament yarn options in terms of denier (thickness), filament count, and color to meet your specific needs.

2. Customization Capabilities: Look for a manufacturer that can customize the yarn properties to achieve the desired performance characteristics for your application.

3. Quality Control: Reputable manufacturers prioritize stringent quality control measures to ensure consistent yarn quality throughout production.

4. Sustainability: Consider manufacturers who prioritize sustainable practices in their production processes.

PP Multifilament Yarn Manufacturers in India

India boasts a thriving textile industry, and several manufacturers specialize in producing high-quality PP multifilament yarn. Utilize online search engines to find a comprehensive list of "pp multifilament yarn manufacturer india" to explore your options.

Conclusion

In conclusion, staying ahead in textile trends requires a keen understanding of market dynamics and innovative materials like PP Multifilament Yarn. By leveraging insights and ideas, businesses can anticipate consumer demands, adapt to industry shifts, and propel their textile ventures forward. With its versatile properties and potential applications, PP Multifilament Yarn offers a promising avenue for textile professionals to explore and capitalize on emerging trends, ensuring they remain at the forefront of the ever-evolving textile landscape. Embracing this dynamic material opens doors to creativity, sustainability, and competitive advantage, paving the way for continued success in the fast-paced world of textiles.

FAQs (Frequently asked questions)

Q1. What are the advantages of PP multifilament yarn over other synthetic fibers like nylon?

A1. While both PP and nylon are synthetic fibers, PP offers several advantages. PP is generally lighter, more water-resistant, and often more cost-effective than nylon. However, nylon might be a better choice for applications requiring higher elasticity.

Q2. Is PP multifilament yarn eco-friendly?

A2. PP itself is not biodegradable. However, some manufacturers are exploring methods for recycling PP waste into new yarns. Look for manufacturers offering recycled PP multifilament yarn options for a more sustainable approach.

Q3. In what textile applications can PP Multifilament Yarn be used?

A3. PP Multifilament Yarn can be used in a wide range of textile applications, including apparel (such as activewear, outerwear, and performance clothing), home textiles (like upholstery, curtains, and bedding), technical textiles (such as geotextiles and industrial fabrics), and various other products like bags, ropes, and nets.