In a world that is increasingly conscious of environmental impact, innovative solutions that combine effectiveness with sustainability are highly sought after. Shot Blaster, a trailblazer in the industry, has harnessed the power of steel shots to offer an eco-friendly approach to surface preparation.

This article delves into the sustainable advantages of using steel shots for surface preparation and how Shot Blaster is leading the charge in promoting environmentally conscious practices.

Introduction

The process of surface preparation is essential in various industries, from manufacturing to construction. Traditionally, this has involved abrasive methods that can generate waste and harmful byproducts. However, with the rise of eco-consciousness, the need for sustainable alternatives has become paramount.

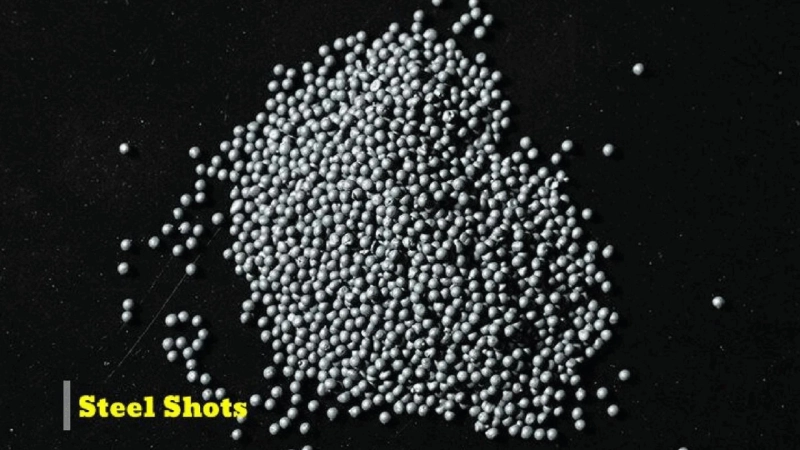

Enter steel shots—a solution that combines effective surface preparation with environmental responsibility.

Eco-Friendly Surface Preparation with Steel Shots

Reduced Waste Generation

One of the standout features of using steel shots is the reduction in waste generation. Unlike traditional abrasives that wear down and need frequent replacement, steel shots are highly durable and can be collected, cleaned, and reused multiple times.

This not only minimizes waste but also reduces the consumption of resources required for abrasive materials. Check now - Steel shots case studies

Recycling and Reusability

Shot Blaster's utilization of steel shots aligns perfectly with the principles of recycling and reusability. Steel shots used in surface preparation can be collected, cleaned, and reintroduced into the process, significantly lowering the environmental footprint.

This circular approach reduces the demand for new abrasive materials and contributes to a more sustainable industry.

Shot Blaster's Eco-Friendly Commitment

Pioneering Green Practices

Shot Blaster's commitment to sustainability extends beyond its innovative use of steel shots. They prioritize eco-friendly practices throughout their operations, from sourcing materials to waste management.

This holistic approach ensures that their clients receive a solution that is aligned with their own environmental goals. Als Know: - Right Steel Shots for Your Application

Reduced Environmental Impact

By choosing Shot Blaster's eco-friendly surface preparation services, industries can contribute to reducing their environmental impact.

This choice not only improves operational efficiency but also showcases a dedication to sustainable practices that resonate with today's environmentally conscious consumers.

Economic Benefits of Eco-Friendly Surface Preparation

Long-Term Cost Savings

Incorporating steel shots into the surface preparation process brings not only environmental benefits but also economic advantages.

The durability and re-usability of steel shots result in fewer material replacements, translating to long-term cost savings for businesses.

Enhanced Efficiency

Steel shots' uniform shape and hardness enhance the efficiency of surface preparation processes.

This efficiency translates to quicker project turnaround times, minimizing energy consumption and associated costs.

Embracing a Sustainable Future

Industry Transformation

Shot Blaster's pioneering use of steel shots for eco-friendly surface preparation is emblematic of an industry-wide shift toward sustainability.

As more businesses adopt eco-conscious practices, the cumulative impact on the environment becomes increasingly positive. Also check: - Steel Shots App

Collaborative Efforts

The journey toward sustainability is a collective effort. By collaborating with innovative partners like "Shot Blaster", industries can share knowledge, resources, and best practices, creating a ripple effect of positive change.

Conclusion

Steel shots have emerged as a beacon of hope in the quest for eco-friendly surface preparation solutions. Shot Blaster's commitment to sustainable practices and their innovative use of steel shots underscores the potential to achieve both effective surface preparation and environmental responsibility.

By embracing such solutions, industries can not only enhance their operational efficiency but also contribute to a greener, more sustainable future.

As Shot Blaster leads the way, others are inspired to follow suit, shaping an industry that prioritizes both quality and the well-being of the planet.

For more details visit - Steel Shots Supplier & Steel Shots Manufacturer

FAQs

Can steel shots be recycled multiple times?

Yes, steel shots used for surface preparation can be collected, cleaned, and recycled multiple times, making them a highly sustainable option.

How does Shot Blaster ensure the eco-friendliness of their operations?

Shot Blaster incorporates eco-friendly practices throughout their operations, from material sourcing to waste management, ensuring a holistic approach to sustainability.

What industries can benefit from Shot Blaster's eco-friendly surface preparation services?

Industries across the board, including manufacturing, construction, and automotive, can benefit from adopting eco-friendly surface preparation practices offered by Shot Blaster.

Does eco-friendly surface preparation with steel shots compromise effectiveness?

Not at all. Steel shots offer effective surface preparation with the added advantage of sustainability, making them a win-win solution.

Where can I learn more about Shot Blaster's eco-friendly practices and services?

To explore how Shot Blaster is revolutionizing surface preparation through eco-friendly practices, visit their official website at www.steelshots.co.