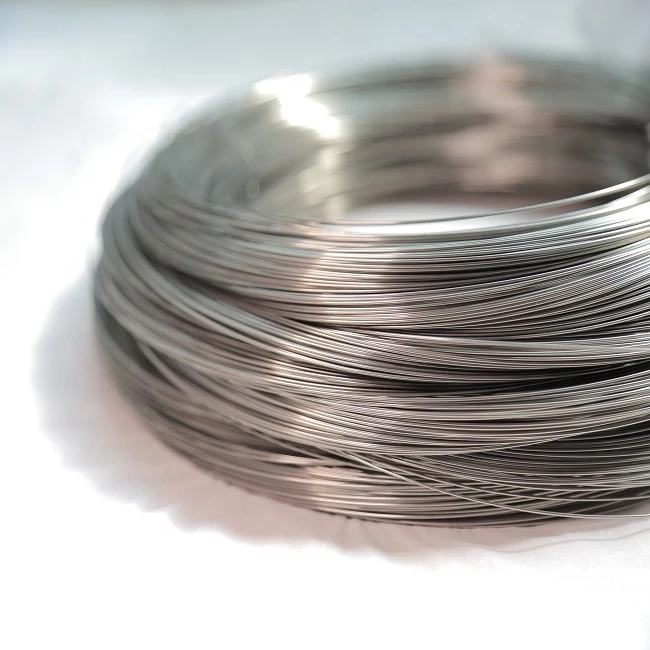

Superelastic Nitinol wire is made from a nickel-titanium (Ni-Ti) alloy known as Nitinol. It is known for its unique properties, including super-elasticity and shape memory, which make it useful in various applications, including medical devices, actuators, and sensors.

Superelastic Nitinol Wire exhibits both super-elasticity and shape memory. It can recover its original shape after deforming and be stretched to high strains without permanent deformation. This property is due to the alloys’ unique combination of high strength and low modulus of elasticity.

In medical applications, super-elastic Nitinol wire is often used for stents, catheter guides, and orthodontic archwires. In these applications, its super-elasticity and shape memory allow it to conform to the body’s contours and return to its original shape, improving patient comfort and reducing the risk of complications.

In addition to its unique properties, super-elastic Nitinol wire is also biocompatible. It does not cause adverse reactions in the body and is highly resistant to corrosion, making it suitable for harsh environments.

Properties of Superelastic Nitinol Wire

Super-elastic Nitinol wire is known for its unique properties, making it highly desirable in various applications, including medical devices, actuators, and sensors. Some of the critical properties of super-elastic Nitinol wire are:

Super-Elasticity: It can be stretched to high strains without undergoing permanent deformation. It can recover its original shape after being deformed. This property is due to the alloys’ unique combination of high strength and low modulus of elasticity.Shape Memory: Super-elastic Nitinol wire exhibits shape memory, meaning it can return to its original shape after deforming. This property is highly desirable in medical applications, allowing the wire to conform to the body’s contours and return to its original form, improving patient comfort and reducing the risk of complications.Biocompatibility: Super-elastic Nitinol wire is biocompatible, meaning it does not cause adverse reactions in the body, making it suitable for medical applications.Corrosion Resistance: Super-elastic Nitinol wire is highly resistant to corrosion, making it suitable for use in harsh environments, including those with high moisture levels or exposure to corrosive chemicals.High Strength: Super-elastic Nitinol wire has a high strength-to-weight ratio, making it suitable for high-stress applications, including those requiring high tensile strength.Industrial Applications Of Superelastic Nitinol Wire

Nitinol Shape Wire Uses & Applications In Various IndustriesApplications Of Superelastic Nitinol Wire has a wide range due to its unique properties, including super-elasticity, shape memory, biocompatibility, and corrosion resistance. Some of the most common applications of super-elastic Nitinol wire are:

Medical Devices: Super-elastic Nitinol wire is widely used in medical devices, such as stents, catheters, and orthodontic appliances, due to its biocompatibility and shape memory properties.Actuators: Super-elastic Nitinol wire is also used as an actuator in devices that require repeated and consistent movements, such as robotic arms and smart fabrics.Sensors: Super-elastic Nitinol wire can be used as a sensor due to its ability to change shape in response to changes in temperature or pressure, making it ideal for use in temperature- or pressure-sensitive devices.Aerospace: Super-elastic Nitinol wire is used in aerospace applications due to its high strength-to-weight ratio and resistance to corrosion, making it suitable for use in harsh environments.Industrial Applications: Super-elastic Nitinol wire is also used in industrial applications, such as valve actuators and fasteners, due to its shape memory and super-elasticity properties.Energy Harvesting: Super-elastic Nitinol wire can be used in energy harvesting applications, such as wearable devices and portable generators, to convert movement into electrical energy.In conclusion, due to its unique combination of properties, superelastic Nitinol wire has a wide range of applications in various fields, including medical devices, actuators, sensors, aerospace, industrial applications, and energy harvesting.