The most common practice followed for chiller plant operation is through the Building Management System (iBMS). However, the chiller plant performance is dependent on various factors like Ambient Temperature, Chilled Water Temperature and the Load Variation, which standard BMS might not be able to consider. In other words, operating a chiller plant just based on the water temperature is not the efficient way. We need a dedicated operating and optimized power & running solution for the chiller plant.

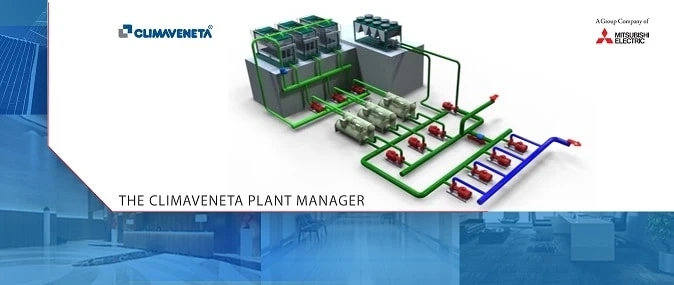

The objective of Chiller Plant Manager is to manage & optimize the operation of Chillers, Water Pumps, and other ancillary equipment in a plant room.

The Climaveneta Plant Manager is designed & developed to operate the plant room in an efficient way without any manual intervention.

CLIMAVENETA CPM – KEY FEATURES

LOAD MANAGEMENT

Temperature Control of CHW Soft Start – gradual loading at start Inrush Current Control Fail Proof – continued operation of the plant based on last command, in case of CPM failure Adaptive Set Point

SEQUENCING

Chiller Rotation Standby takeover-in case of chiller failure Chiller start up sequencing Chiller shut down sequencing

III. USER INTERFACE

System Status Display Alerts & Alarm Logging System Security for Various Levels Third Party Interface Cloud Integration Remote Monitoring

For more details visit us

0