Timex Metals is known as one of the leading Wire Mesh Manufacturers in India. We offer the finest quality Stainless Steel Wire Mesh to various industries around the globe. Our aptitude in heat treatment gives us a preferred position in producing and exporting with a nearby and specified chemistry and accomplishing the required mechanical properties.

Understanding Wire Mesh

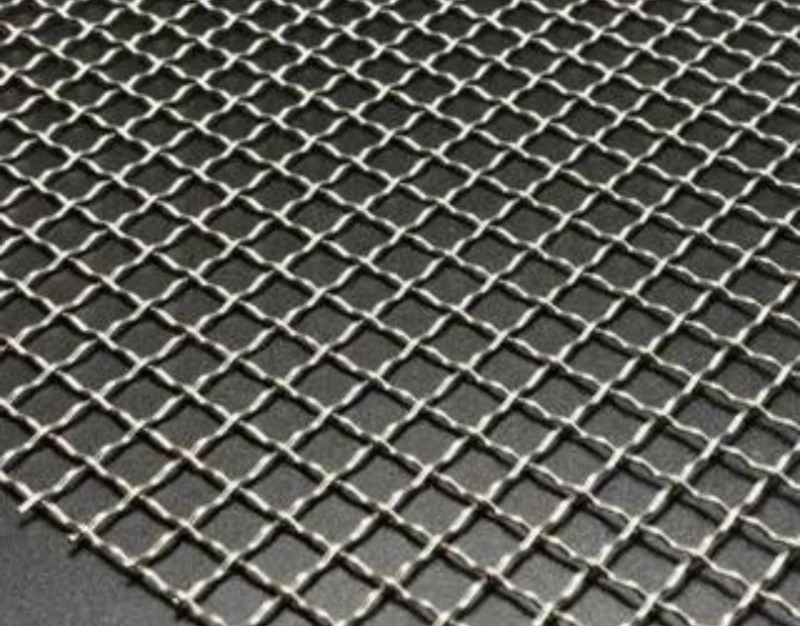

Before delving into the manufacturing intricacies, let's first grasp the essence of wire mesh itself. Wire mesh is a versatile material of interconnected wires, typically made from metals like stainless steel, galvanized steel, or aluminum. These woven or welded meshes offer a unique combination of strength, durability, and flexibility, making them ideal for various applications.

Types of Wire Mesh

The wire mesh industry in India encompasses a diverse array of products, each tailored to specific requirements. Here are some of the most common types:

Woven Wire Mesh: Crafted by interweaving wires at perpendicular angles, this mesh offers excellent strength and versatility and is suitable for filtration, reinforcement, and security applications.Welded Wire Mesh: Formed by welding intersecting wires at their junctions, this mesh boasts exceptional rigidity and load-bearing capacity, making it ideal for concrete reinforcement and industrial flooring.Perforated Metal Mesh: Created by punching or stamping holes in metal sheets, this mesh offers precise openings and is commonly used in filtration, ventilation, and architectural applications.Knitted Wire Mesh: This mesh, featuring a flexible and porous structure, is produced by knitting or interlooping wires. It finds applications in erosion control, insect screening, and decorative purposes.Applications of Wire Mesh

The versatility of wire mesh extends across numerous industries, each leveraging its unique properties for specific applications. Some prominent examples include:

Construction: Wire mesh is widely used for concrete reinforcement, security fencing, and architectural cladding, contributing to the structural integrity and aesthetic appeal of buildings.Industrial: Wire mesh is crucial in various industrial processes, from filtration and screening to machine guarding and conveyor belts, ensuring efficiency and safety.Agriculture: Employed in animal enclosures, crop protection, and soil reinforcement, wire mesh products are essential for sustainable agricultural practices.Automotive and Aerospace: Wire mesh components are utilized in vehicle interiors, engine components, and aircraft structures, providing strength, durability, and weight reduction benefits.

Wire Mesh Manufacturing Process

Manufacturing wire mesh in India involves intricate processes, each contributing to the final product's quality and performance. Here's a detailed overview of the wire mesh manufacturing process:

Raw Material Procurement:

The journey begins with sourcing high-quality raw materials, primarily metal wires and rods. Indian manufacturers often rely on domestic suppliers or import premium-grade materials to meet specific requirements. Common materials include stainless steel, galvanized steel, aluminum, copper, and various alloys.

Wire Drawing:

The raw materials undergo a wire drawing process, where they are pulled through a series of progressively smaller die openings, reducing their cross-sectional area and increasing their length. This process ensures the wires' uniform thickness, strength, and surface finish, which is essential for producing consistent wire mesh products.

Weaving or Welding:

Depending on the desired mesh type, the drawn wires are either woven or welded to create the mesh structure:

Weaving: For woven wire mesh, the wires are interlaced at perpendicular angles using specialized weaving machines, creating a flexible and robust mesh structure.Welding: In welded wire mesh, the wires are arranged in a grid pattern, and the intersections are fused using resistance welding or laser welding techniques, resulting in a rigid and durable mesh.

Finishing Processes

Once the mesh structure is formed, it may undergo various finishing processes to enhance its properties or meet specific application requirements. These processes may include:

Heat Treatment: Annealing, quenching, or tempering to modify the mesh's mechanical properties, such as strength, flexibility, or hardness.Surface Treatment: Galvanizing, powder coating, or electroplating to improve corrosion resistance, aesthetics, or conductivity.Cutting and Forming: Laser cutting, shearing, or bending to create custom shapes, sizes, and profiles for specific applications.

Quality Control

Wire Mesh Manufacturer in India strongly emphasise quality control measures to ensure their products meet stringent industry standards and customer requirements. These measures may include:

Dimensional Inspections: Verifying mesh aperture sizes, wire diameters, and overall dimensions to ensure conformity to specifications.Mechanical Testing: Conducting tensile strength, elongation, and hardness tests to evaluate the mesh's performance under various loading conditions.Corrosion Resistance Testing: The mesh's resistance to corrosive environments is assessed through salt spray or chemical immersion tests.Visual Inspections: Examine the mesh for surface defects, weld integrity, and overall appearance to maintain consistent quality.

Wire Mesh Suppliers in India understand their client's needs and offer high-quality items that meet industry standards. We provide the most dependable Shaft Sleeve Pump Manufacturer in India, Stainless Steel Manhole Cover Manufacturers in India, and Stainless Steel Column Pipe Adapter Manufacturers in India.

Product Source: Wire Mesh Supplier in India