Introduction:

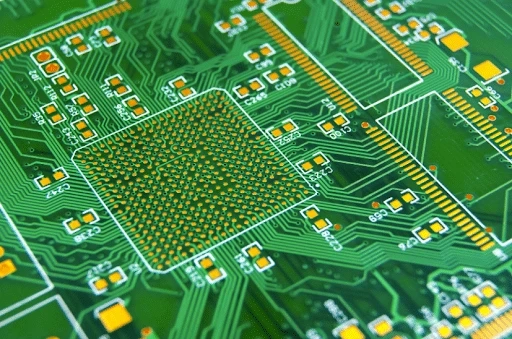

Prototyping is a crucial step in PCB (Printed Circuit Board) design and assembly. It helps in identifying and fixing issues before mass production, ensuring that the final product works as intended. In this blog, we will explore the importance of prototyping in electronic assembly, the benefits it offers, and the steps involved in creating a successful prototype.

What is PCB Prototyping?

PCB prototyping is the process of creating a preliminary version of a PCB to test its functionality. This prototype helps engineers and designers to see how the final product will perform, allowing them to make necessary adjustments.

Why is Prototyping Important in Electronic Assembly?

Prototyping plays a critical role in electronic assembly for several reasons:

Error Detection:

Identify Flaws Early: Prototypes allow for the early detection of design flaws, which can be corrected before full-scale production begins.

Avoid Costly Mistakes: Fixing errors in the prototype stage is much cheaper and easier than addressing them after production.

Functional Testing:

Performance Check: Testing the prototype helps ensure that the PCB functions correctly and meets all required specifications.

Real-World Conditions: Prototypes can be tested under real-world conditions to see how they perform in various environments.

Design Verification:

Verify Design: Prototyping allows designers to verify that their design works as expected.

Iterative Improvements: It provides an opportunity to make iterative improvements, refining the design before final production.

Steps in PCB Prototyping

Concept and Design:

Initial Concept: Start with an initial concept or idea for the PCB.

Schematic Design: Create a schematic diagram to outline the electrical connections.

PCB Layout:

Component Placement: Arrange the components on the PCB layout.

Routing: Connect the components with copper traces to ensure proper electrical connectivity.

Prototype Fabrication:

Fabrication: Use a PCB manufacturer to produce the physical prototype.

Component Assembly: Assemble the components onto the fabricated PCB.

Testing and Evaluation:

Functional Testing: Test the prototype to ensure it functions as intended.

Evaluation: Evaluate the prototype’s performance and identify any issues.

Iteration and Improvement:

Refinement: Make necessary improvements based on the testing results.

Re-Prototyping: Create a new prototype if significant changes are made.

Benefits of Prototyping in PCB Design and Assembly

Cost Savings:

Reduce Waste: Prototyping helps reduce waste by identifying issues early.

Optimize Resources: Use resources more efficiently by avoiding large-scale production errors.

Improved Quality:

High-Quality Products: Prototyping ensures high-quality final products by allowing for thorough testing and refinement.

Reliability: Increase the reliability of the PCB by addressing potential issues beforehand.

Faster Time to Market:

Speed Up Production: Identifying and fixing problems early can speed up the overall production process.

Competitive Advantage: Get your product to market faster, giving you a competitive edge.

Customer Satisfaction:

Meet Expectations: Ensure that the final product meets customer expectations and requirements.

Reduce Returns: Lower the chances of returns and dissatisfaction by delivering a high-quality, reliable product.

Best Practices for Effective PCB Prototyping

Use High-Quality Materials:

Reliable Components: Use high-quality, reliable components for your prototypes.

Durable Materials: Ensure the PCB is made from durable materials that can withstand testing.

Collaborate with Experts:

Expert Input: Work with experienced engineers and designers to ensure the prototype is accurate.

Feedback Loop: Create a feedback loop to continuously improve the design.

Thorough Testing:

Comprehensive Testing: Conduct thorough testing under various conditions to ensure the prototype meets all requirements.

Document Results: Document all test results and use them to make informed improvements.

Iterate Quickly:

Rapid Prototyping: Use rapid prototyping techniques to quickly create and test new versions.

Agile Approach: Adopt an agile approach to make continuous improvements.

Conclusion:

Prototyping is an essential part of the PCB design and assembly process. It helps identify and fix issues early, ensuring the final product is of high quality and performs reliably. By following best practices and thoroughly testing prototypes, you can save costs, improve quality, and speed up time to market. Whether you are designing PCBs for consumer electronics, industrial applications, or any other purpose, prototyping is a step you cannot afford to skip.