caster tip is used for crystallization forming and size control of aluminum strips and foil blanks in Aluminum Strip Casting. Email: sales@adtechamm.com

The adjustment of the Caster tip's opening degree and the plate shape's adjustment is important and reused in the production of aluminum products. Therefore, it has a great impact on product quality.

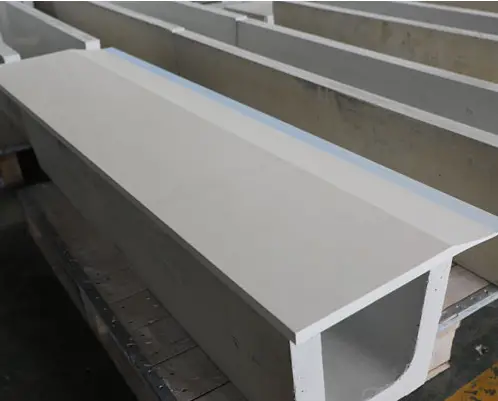

In the related art, the caster tip includes an upper clamping plate located at the upper part of the casting nozzle and a lower clamping plate located at the lower part of the casting nozzle. The upper clamping plate and the lower clamping plate clamp the casting nozzle through a threaded connection.

The influence of Adtech high-aluminum Castertip on the casting speed, the height of the nozzle cavity exit, and the total length of the cavity.

The numerical simulation results of variable density and constant density melts were compared, and the flow field and temperature field distribution of high-temperature shallow aluminum melts were revealed, and it was concluded that the numerical simulation should adopt a three-dimensional model.

The melt flow direction and outlet temperature increase with the casting speed. Changing the inlet velocity distribution can improve the uniformity of the melt outlet temperature and velocity in the cavity.

Changing the number of shunt blocks can improve the outlet velocity distribution and temperature distribution uniformity.

Appropriately reducing the opening degree of the cavity can obtain a more uniform outlet velocity distribution and temperature distribution.

Increasing the cavity length can obtain a more uniform melt outlet velocity distribution and a more uniform temperature distribution.

In practical engineering applications, it is reasonable to regard variable density as constant density. Numerical simulation results and analysis conclusions provide an important basis for the best matching parameters of continuous casting and rolling, especially rapid casting.

ADTECH conducted a real measurement experiment on the surface temperature of the caster tip and collect relevant data. The results show that the numerical simulation conclusions are consistent with the experimental test data conclusions. The temperature test experiment establishes the basis for the simulated temperature boundary conditions and verifies the correctness of the relevant conclusions. Sex.

On the basis of the simulation calculation of the convection field and temperature field of the high aluminum Castertip, the fixed shunt block of the existing casting nozzle cavity is eliminated, and a row of controllable headboxes are set in the front box close to the casting nozzle.

0