Looking to improve your material handling processes? Discover the benefits of a roller carriage. This comprehensive guide explores the functionality and advantages of a roller carriage, tips for selecting the right one, and insights into its applications across various industries. Whether you're involved in manufacturing, logistics, or warehouse management, the roller carriage can enhance efficiency and mobility in your material handling operations.

Introduction

Efficient material handling is essential in industries where the movement of goods and materials is a critical part of the workflow. The roller carriage is a versatile equipment component that plays a crucial role in enhancing efficiency and mobility in material handling tasks. Whether it's in manufacturing facilities, distribution centers, or warehouses, the roller carriage offers a range of benefits that streamline processes and optimize productivity. In this guide, we'll delve into the functionality, advantages, and applications of the roller carriage, helping you make informed decisions for your material handling needs.

Understanding the Roller Carriage

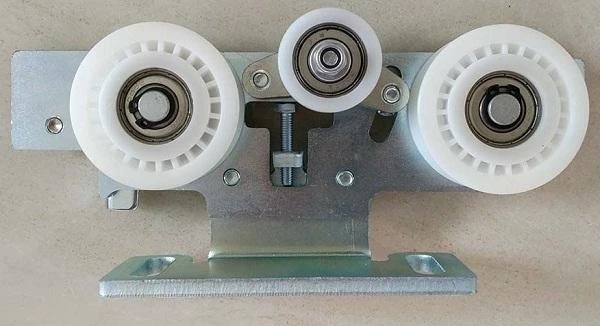

The roller carriage is a component that forms an integral part of various material handling systems. It consists of a framework with built-in rollers or wheels that facilitate the movement of objects along a predetermined path. The design and configuration of the roller carriage can vary depending on the specific application and requirements. It can be used in conjunction with conveyors, tracks, or other support structures to create efficient material flow and transportation systems.

Advantages of the Roller Carriage

The roller carriage offers numerous advantages that contribute to improved efficiency and mobility in material handling operations. Here are some key benefits:

Ease of Movement: With its built-in rollers or wheels, the roller carriage enables smooth and effortless movement of objects. This reduces the need for manual pushing or pulling, minimizing physical strain on workers and increasing operational efficiency.

Flexibility and Adaptability: The roller carriage can be customized and configured to accommodate various types of materials, sizes, and weights. This flexibility allows for easy adaptation to changing production requirements or handling different product lines.

Enhanced Speed and Throughput: By utilizing the roller carriage, materials can be transported quickly and efficiently from one location to another. This results in improved productivity and reduced cycle times, ultimately enhancing overall throughput.

Reduced Damage and Product Loss: The roller carriage provides a controlled and stable surface for transporting goods, reducing the risk of damage or product loss during handling. The smooth movement of materials minimizes the likelihood of collisions or mishaps that could result in costly damages.

Space Optimization: The compact design of the roller carriage allows for efficient use of space in warehouses or production facilities. It can be integrated into existing systems or incorporated into new layouts, optimizing storage capacity and material flow.

Selecting the Right Roller Carriage

To maximize the benefits of the roller carriage, it's important to select the right one for your specific needs. Consider the following factors when choosing a roller carriage:

Load Capacity: Determine the maximum weight and size of the objects you'll be handling. Select a roller carriage with a load capacity that exceeds your requirements to ensure safe and efficient transportation.

Roller Type: There are different roller types available, such as gravity rollers, ball transfer rollers, or powered rollers. Choose the appropriate roller type based on your material handling processes and the nature of the objects being transported.

Durability and Maintenance: Look for roller carriages constructed from durable materials that can withstand the demands of your industry. Additionally, consider the maintenance requirements and ensure easy access for cleaning and lubrication.

Compatibility: If integrating the roller carriage into an existing material handling system, ensure compatibility with the conveyors, tracks, or support structures in place. Proper alignment and connection will optimize performance and prevent disruptions