It is imperative to keep one step ahead of the competition in the dynamic world of business. One way to achieve this is by leveraging a powerful Material Requirements Planning (MRP) system. This comprehensive guide will delve into the intricacies of MRP systems, highlighting their benefits, functionality, and implementation strategies to help you optimize your business operations.

What is an MRP System?

An MRP system is a software solution designed to manage manufacturing processes, inventory levels, and production scheduling. By ensuring that materials and components are available when needed, an MRP system helps businesses maintain optimal inventory levels, reduce waste, and improve overall efficiency.

The Importance of MRP Systems in Modern Business

1. Enhanced Inventory Management

The management of inventory is an essential component of any business. An MRP system provides real-time visibility into inventory levels, ensuring that businesses can meet customer demands without overstocking or understocking products. This balance is crucial for maintaining customer satisfaction and minimizing carrying costs.

2. Improved Production Planning

An MRP system streamlines production planning by accurately forecasting demand and aligning it with production schedules. This ensures that resources are allocated efficiently, reducing lead times and enhancing the overall production process.

3. Cost Reduction

By optimizing inventory levels and production schedules, an MRP system helps businesses reduce costs associated with excess inventory, production delays, and stockouts. This cost reduction directly impacts the bottom line, improving profitability.

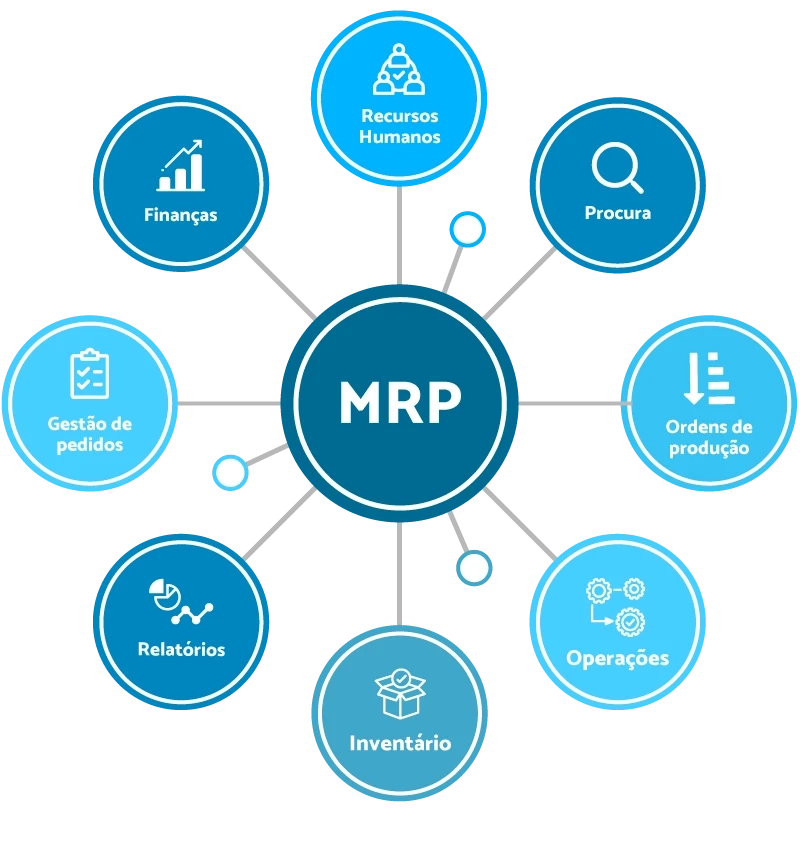

Key Features of an Effective MRP System

1. Demand Forecasting

The ability to forecast demand is essential to any MRP system. Accurate forecasts enable businesses to plan their production schedules effectively, ensuring that they can meet customer demand without overproducing or underproducing goods.

2. Inventory Control

Efficient inventory management is crucial to reducing waste and increasing productivity. An MRP system provides real-time data on inventory levels, helping businesses maintain the right balance of materials and components.

3. Production Scheduling

Production scheduling is a complex process that requires careful coordination of resources, labor, and equipment. An MRP system automates this process, ensuring that production runs smoothly and efficiently.

4. Capacity Planning

Determining the production capacity required to satisfy fluctuating needs is the process of capacity planning. An MRP system helps businesses plan for future growth by analyzing historical data and predicting future requirements.

How to Implement an MRP System

1. Assess Your Business Needs

Before implementing an MRP system, it is crucial to assess your business needs. This involves identifying the specific challenges you face in inventory management, production planning, and demand forecasting.

2. Choose the Right MRP System

There are various MRP systems available on the market, each with its unique features and capabilities. It is essential to choose a system that aligns with your business needs and goals.

3. Train Your Team

Implementing an MRP system requires a well-trained team. Provide comprehensive training to ensure that your employees understand how to use the system effectively.

4. Monitor and Evaluate

Once the MRP system is in place, continuously monitor its performance and evaluate its impact on your business operations. Make the required changes to maximize its functionality.

Benefits of MRP Systems

1. Increased Efficiency

An MRP system automates many of the manual processes involved in inventory management and production planning, leading to increased efficiency and productivity.

2. Better Decision Making

With real-time data and accurate forecasts, an MRP system enables businesses to make informed decisions about inventory levels, production schedules, and capacity planning.

3. Enhanced Customer Satisfaction

By ensuring that products are available when customers need them, an MRP system helps businesses improve customer satisfaction and loyalty.

4. Reduced Waste

An MRP system helps businesses minimize waste by ensuring that materials and components are used efficiently and effectively.

Challenges of MRP Systems

1. High Initial Costs

There are expenses involved in implementing an MRP system, including those related to software, hardware, and training.

2. Complexity

MRP systems can be complex to implement and require significant time and resources to set up and maintain.

3. Data Accuracy

The precision of the data entered into an MRP system determines its efficacy. Inaccurate data can lead to incorrect forecasts and production schedules.

Conclusion

In conclusion, an MRP system is a powerful tool that can help businesses optimize their inventory management, production planning, and overall efficiency. While there are challenges associated with implementing an MRP system, the benefits far outweigh the costs. By choosing the right system, training your team, and continuously monitoring its performance, you can achieve significant improvements in your business operations.

FAQs

1. What is an MRP system?

An MRP system is a software solution designed to manage manufacturing processes, inventory levels, and production scheduling to ensure optimal efficiency.

2. How does an MRP system improve inventory management?

An MRP system provides real-time visibility into inventory levels, helping businesses maintain the right balance of materials and components, reducing waste and carrying costs.

3. What are the key features of an effective MRP system?

Key features include demand forecasting, inventory control, production scheduling, and capacity planning.

4. What are the challenges of implementing an MRP system?

Challenges include high initial costs, system complexity, and the need for accurate data input.

5. How can businesses benefit from an MRP system?

Benefits include increased efficiency, better decision-making, enhanced customer satisfaction, and reduced waste.